Environmentally friendly degradable fibers and a preparing method thereof

A technology that degrades fibers and is environmentally friendly. It is applied in the direction of fiber chemical characteristics, conjugated synthetic polymer rayon, and conjugated rayon. It can solve problems such as poor thermal stability, limited applications, and low melting point, and achieve excellent resilience. , Improve the mechanical properties, the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

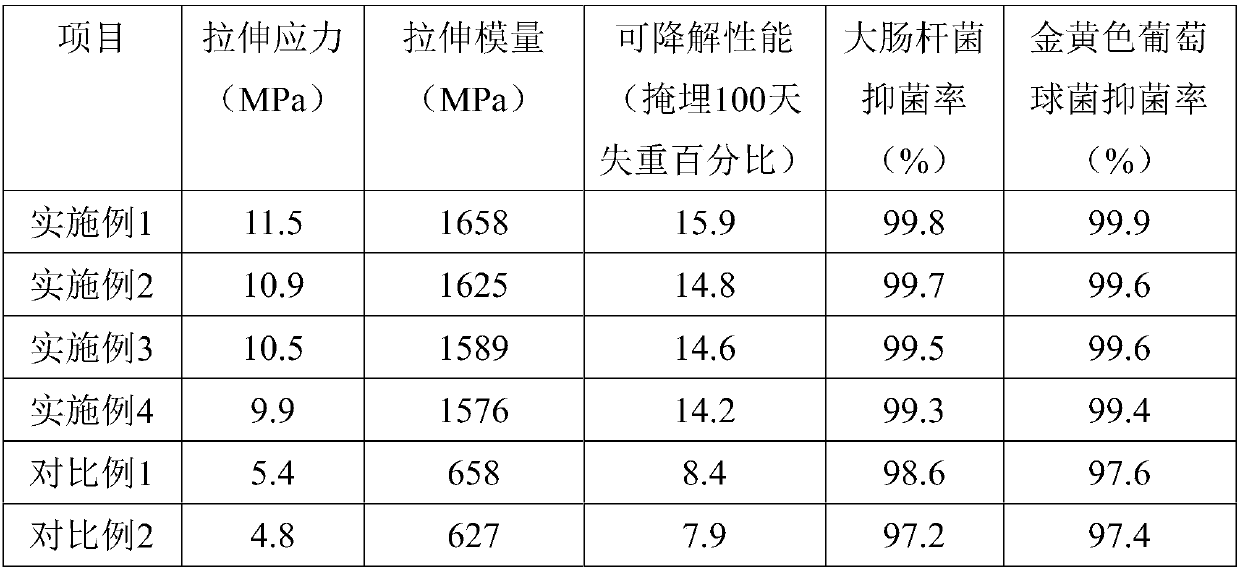

Examples

Embodiment 1

[0022] An environmentally friendly degradable fiber, including the following raw materials: 86g polylactic acid, 25g straw fiber, 12g tert-butyl peroxyacetate, 9g antibacterial agent, 6g isocyanate compatibilizer, acetic anhydride 10g, tert-butanol 5g, glycerin 22g, antioxidant sodium thiosulfate 4g, light stabilizer 944 0.7g. The antibacterial agent includes the following raw materials by weight: 4g of copper citrate, 2.25g of copper rosinate, 1.5g of sodium silicate, 0.6g of nano silicon dioxide, and 0.75g of attapulgite.

[0023] The preparation method of the above-mentioned environment-friendly degradable fiber comprises the following steps:

[0024] (1) Preparation of antibacterial agent: Add sodium silicate, nano-silica, and attapulgite to the mixer, stir at 250r / min for 26min, add copper citrate and copper rosinate, mix and stir for 36min, and then put it into a ball mill for grinding An antibacterial agent with a particle size of 200-300 meshes was obtained; wherein, ...

Embodiment 2

[0028] An environmentally friendly degradable fiber, including the following raw materials: 88g polylactic acid, 22g straw fiber, 16g tert-butyl peroxyacetate, 8g antibacterial agent, 8g isocyanate compatibilizer, 12g acetic anhydride, 5g tert-butanol , glycerol 20g, antioxidant citric acid 5g, light stabilizer 2908 0.7g; antibacterial agent includes the raw materials of following weight: copper citrate 3.7g, rosinic acid copper 2.1g, sodium silicate 1.1g, nano silicon dioxide 0.4 g, attapulgite 0.7g.

[0029] The preparation method of the above-mentioned environment-friendly degradable fiber comprises the following steps:

[0030] (1) Preparation of antibacterial agent: Add sodium silicate, nano-silica, and attapulgite to the mixer, stir at 300r / min for 20min, add copper citrate and copper rosinate, mix and stir for 34min, and then put it into a ball mill for grinding The antibacterial agent with a particle size of 200-300 meshes was obtained; wherein, the ball mill used a p...

Embodiment 3

[0034] An environmentally friendly degradable fiber, including the following raw materials: 92g of polylactic acid, 28g of straw fiber, 14g of tert-butyl peroxyacetate, 10g of antibacterial agent, 8g of isocyanate-type compatibilizer, 13g of acetic anhydride, and 5g of tert-butanol , glycerol 22g, antioxidant dibutylcresol 3g, light stabilizer 622 1.2g; antibacterial agent includes the raw materials of following weight: copper citrate 3.7g, copper rosinate 3g, sodium silicate 1.6g, nano silicon dioxide 0.9 g, attapulgite 0.8g.

[0035] The preparation method of the above-mentioned environment-friendly degradable fiber comprises the following steps:

[0036] (1) Preparation of antibacterial agent: Add sodium silicate, nano-silica, and attapulgite to the mixer, stir at 220r / min for 25min, add copper citrate and copper rosinate, mix and stir for 36min, and then put it into a ball mill for grinding The antibacterial agent with a particle size of 200-300 meshes was obtained; among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com