PLGA/zwitterionic composite porous bone tissue engineering scaffold and preparation method thereof

A tissue engineering scaffold, zwitterion technology, applied in tissue regeneration, pharmaceutical formulations, coatings, etc., can solve the problems of unstable degradation rate, lack of efficient slow release performance of growth factors, tissue inflammatory response, etc., to improve the biological phase. Capacitive and biosafety properties, stable degradation, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

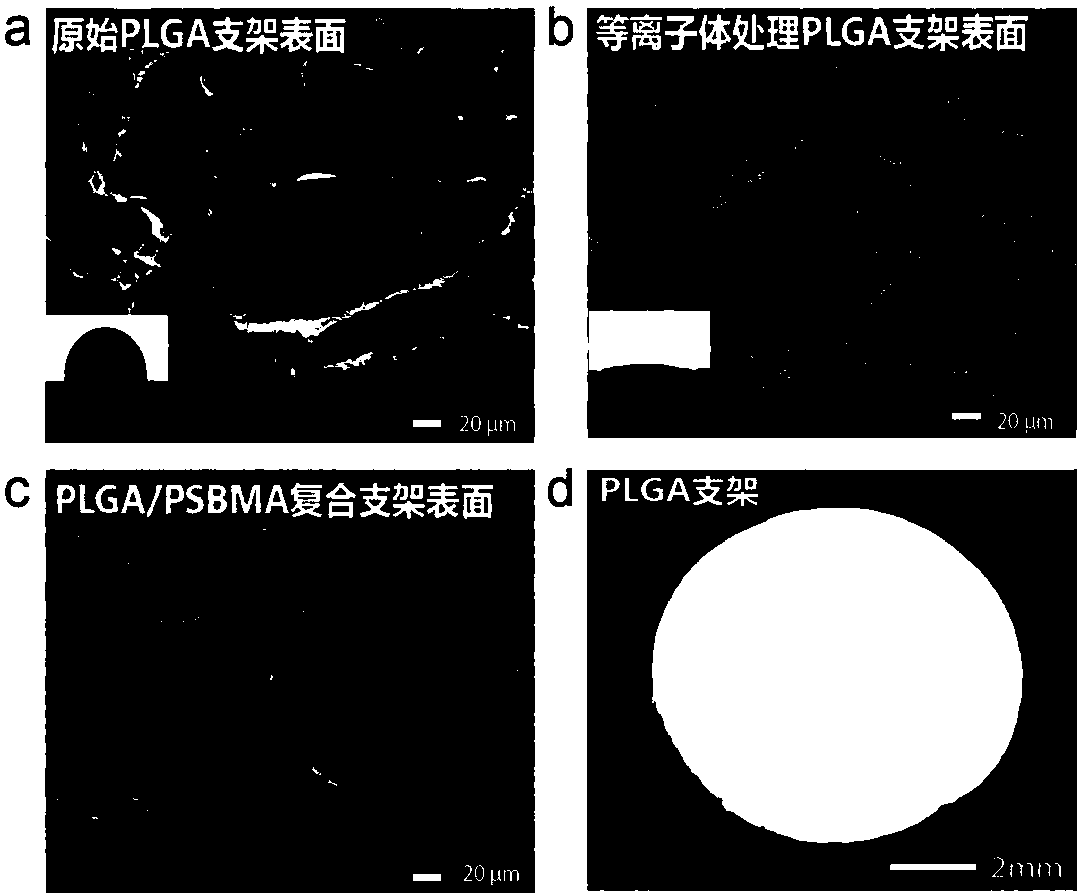

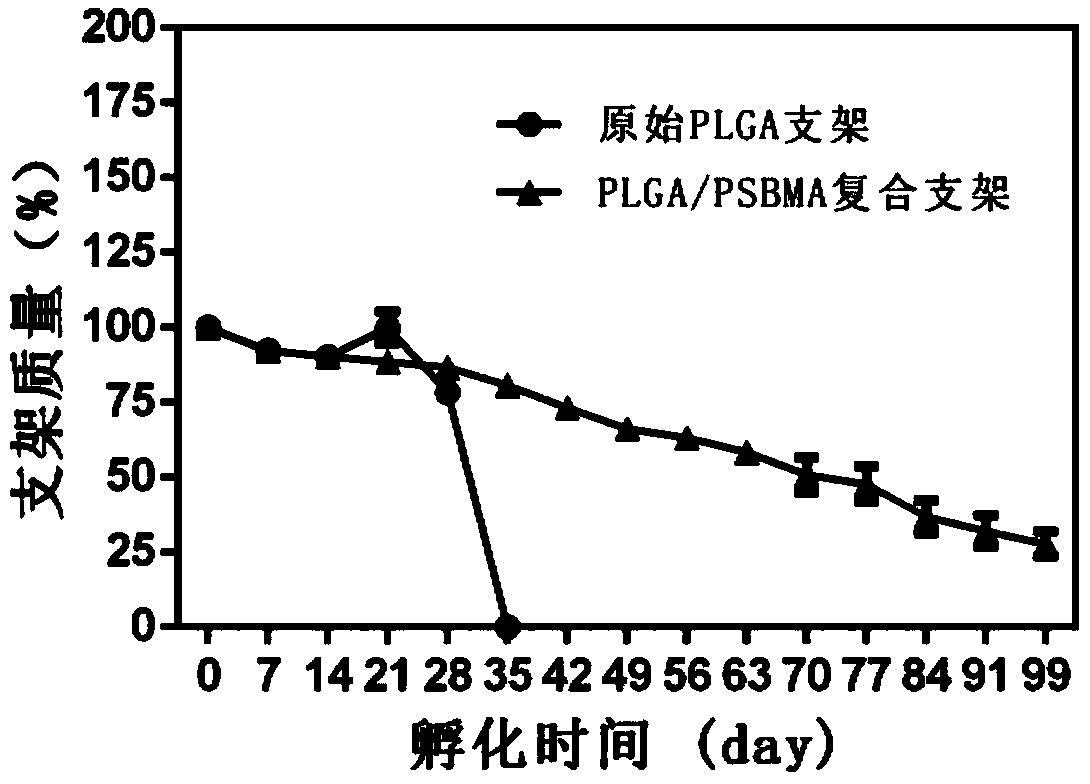

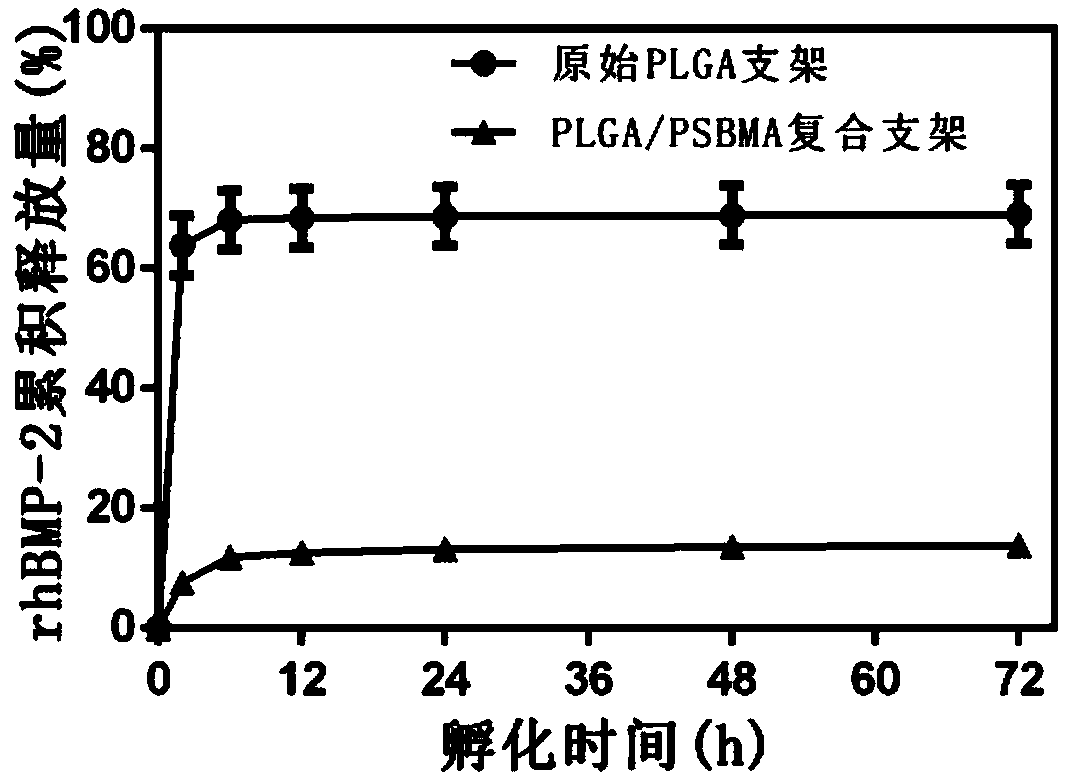

[0027] The preparation method of the PLGA / zwitterionic composite porous bone tissue engineering scaffold is as follows:

[0028] (1) Preparation of PLGA polymer

[0029] With 0.43g of polyethylene glycol (PEG) with a molecular weight of 700 as the initiator, and 100 μL of stannous isooctanoate as a catalyst with a concentration of 8% w / v, pass through 0.1g of lactide and 9.9g of glycolide at a temperature of 200 ° C. After reacting for 24 hours in methanol, it was settled in methanol and then dried under vacuum to obtain PLGA polymer.

[0030] (2) Preparation of porous PLGA scaffolds

[0031] The PLGA polymer prepared in step (1) is dissolved in 1,4-dioxane to form a solution with a concentration ratio of 2 wt%, and after dissolving, it is injected into a polytetrafluoroethylene cake mold and frozen at -20°C After 4 hours, it was freeze-dried at -50° C. for 12 hours under vacuum conditions to obtain a porous PLGA scaffold with a pore size of about 300 μm.

[0032] (3) Plasm...

Embodiment 2

[0038] The preparation method of the PLGA / zwitterionic composite porous bone tissue engineering scaffold is as follows:

[0039] (1) Preparation of PLGA polymer

[0040] Using 0.3g of PEG with a molecular weight of 1000 as the initiator, and 100 μL of stannous octoate with a concentration of 8% w / v as the catalyst, react 7.5g of lactide and 2.5g of glycolide at a temperature of 140°C for 24h, and pass through methanol After settling in medium, dry under vacuum condition to obtain PLGA polymer.

[0041] (2) Preparation of porous PLGA scaffolds

[0042]Dissolving the PLGA polymer prepared in step (1) in 1,4-dioxane to form a solution with a concentration ratio of 10 wt%, inject it into a polytetrafluoroethylene cake mold after dissolving, and freeze at -60°C After 12 hours, it was freeze-dried at -60° C. for 36 hours under vacuum conditions to obtain a porous PLGA scaffold with a pore size of about 200 μm.

[0043] (3) Plasma surface treatment of porous PLGA scaffolds

[004...

Embodiment 3

[0049] The preparation method of the PLGA / zwitterionic composite porous bone tissue engineering scaffold is as follows:

[0050] (1) Preparation of PLGA polymer

[0051] Using 0.15g of PEG with a molecular weight of 2000 as the initiator, and 100 μL of stannous octoate with a concentration of 8% w / v as the catalyst, react 9.9g of lactide and 0.1g of glycolide at a temperature of 100°C for 72h, and pass through methanol After settling in medium, dry under vacuum condition to obtain PLGA polymer.

[0052] (2) Preparation of porous PLGA scaffolds

[0053] Dissolving the PLGA polymer prepared in step (1) in 1,4-dioxane to form a solution with a concentration ratio of 20 wt%, inject it into a polytetrafluoroethylene cake mold after dissolving, and freeze at -80°C After 36 hours, it was freeze-dried at -80° C. for 96 hours under vacuum conditions to obtain a porous PLGA scaffold with a pore size of about 20 μm.

[0054] (3) Plasma surface treatment of porous PLGA scaffolds

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com