Fluorinated graphene with carbonyl fluoride semi-ionic bonds and lithium battery positive pole material

A technology of fluorinated graphene and positive electrode materials, applied in graphene, battery electrodes, positive electrodes, etc., can solve problems such as reducing specific energy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Put 10g of graphene raw material into the fluorination equipment, pass in the fluorination gas nitrogen trifluoride, keep the pressure at 100 kPa, and react at 430°C for 12 hours to obtain about 22.7g of fluorinated graphene, and calculate the fluorine-to-carbon ratio is 0.8;

[0026] Step 2: The electrochemical performance test of the fluorinated graphene material obtained in step 1 as a lithium battery cathode material:

[0027] 1) Working electrode: a mixed material of fluorinated graphene, acetylene black and polyvinylidene fluoride in a mass ratio of 8:1:1;

[0028] 2) Counter electrode: lithium metal sheet;

[0029] 3) Solution: 1Mol / l lithium hexafluorophosphate solution dissolved in ethylene carbonate and dimethyl carbonate (volume ratio 1:1);

[0030] 4) Discharge cut-off voltage: 1.5 V;

[0031] 5) Discharge current: 20 mA / g, 1 A / g, 2 A / g, 5 A / g, 10 A / g;

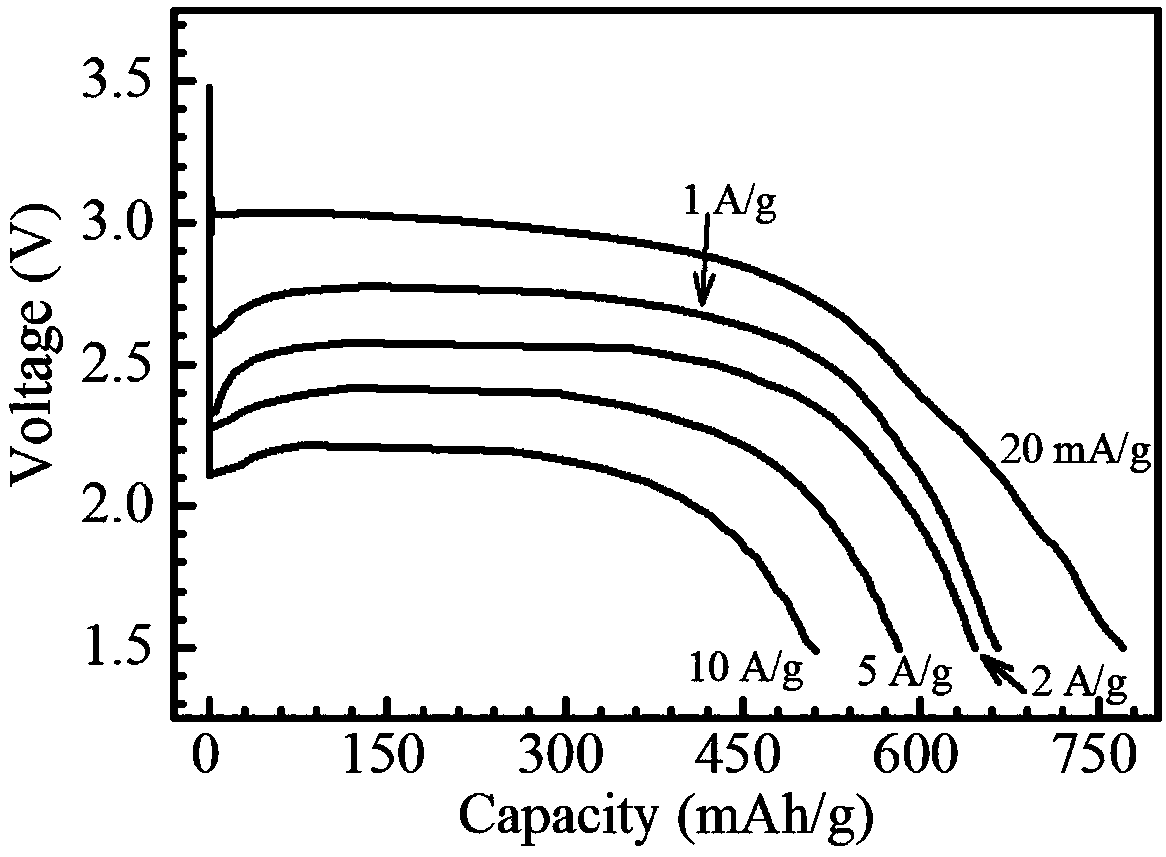

[0032] Performance results such as figure 1 As shown, the material exhibits excellent rate p...

Embodiment 2

[0035] Step 1: Put 10g of graphene raw material into the fluorination equipment, pass in fluorine gas, fluorine gas, keep the pressure at 120 kPa, and react at 350°C for 16 hours to obtain 17.9 g of fluorinated graphene, and the calculated fluorine-to-carbon ratio is 0.5 ;

[0036] Step 2: The electrochemical performance test of the fluorinated graphene material obtained in step 1 as a lithium battery cathode material:

[0037] 1) Working electrode: a mixed material of fluorinated graphene, acetylene black and polyvinylidene fluoride in a mass ratio of 8:1:1;

[0038] 2) Counter electrode: lithium metal sheet;

[0039] 3) Solution: 1Mol / l lithium hexafluorophosphate solution dissolved in ethylene carbonate and dimethyl carbonate (volume ratio 1:1);

[0040] 4) Discharge cut-off voltage: 1.5 V;

[0041] 5) Discharge current: 20 mA / g, 1 A / g, 2 A / g, 5 A / g, 10 A / g;

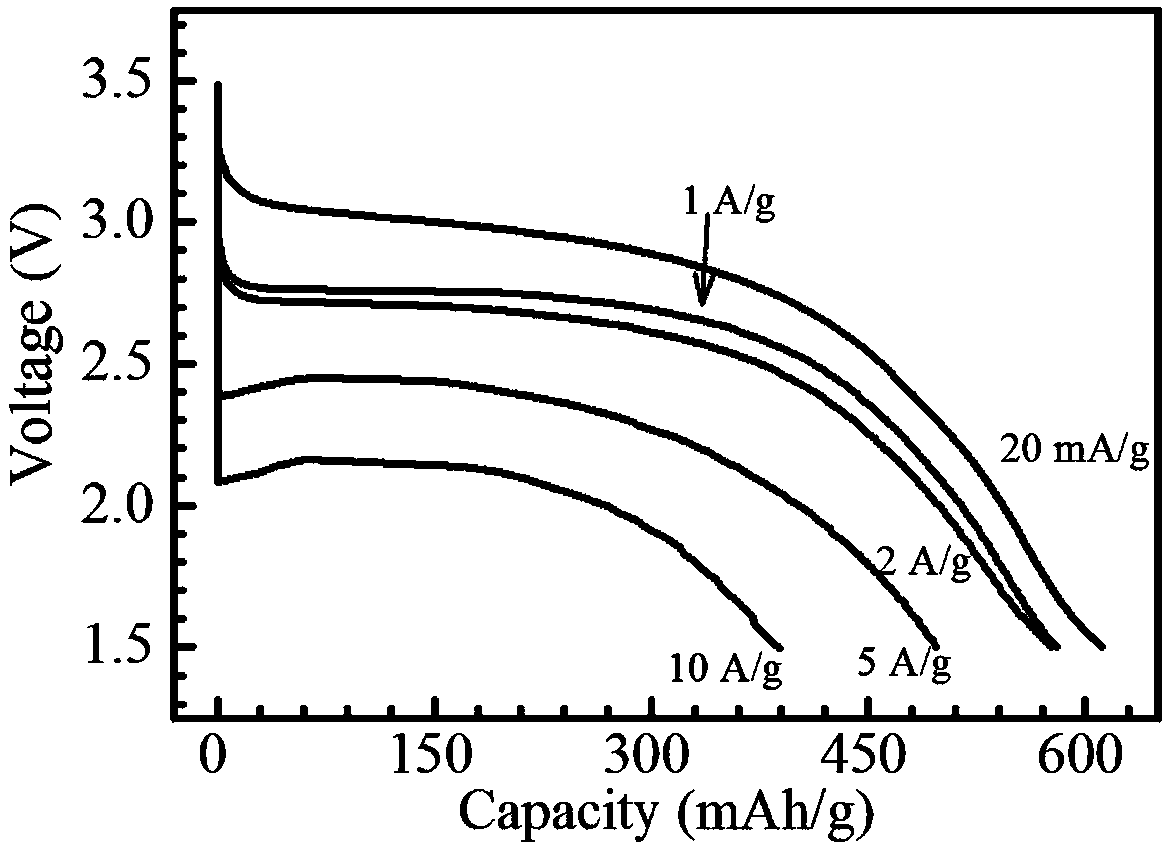

[0042] The result is as image 3 As shown, the material exhibits excellent rate performance, achieving a speci...

Embodiment 3

[0045] Step 1: Put 10g of graphene raw material into the fluorination equipment, pass in the fluorination gas boron trifluoride, keep the pressure at 90 kPa, and react at 500°C for 10 hours to obtain 24.1g of fluorinated graphene, in which the proportion of fluorine to carbon is about is 0.95;

[0046] Step 2: The electrochemical performance test of the fluorinated graphene material obtained in step 1 as a lithium battery cathode material:

[0047] 1) Working electrode: a mixed material of fluorinated graphene, acetylene black and polyvinylidene fluoride in a mass ratio of 8:1:1;

[0048] 2) Counter electrode: lithium metal sheet;

[0049] 3) Solution: 1Mol / l lithium hexafluorophosphate solution dissolved in ethylene carbonate and dimethyl carbonate (volume ratio 1:1);

[0050] 4) Discharge cut-off voltage: 1.5 V;

[0051] 5) Discharge current: 20 mA / g, 1 A / g, 2 A / g, 5 A / g, 10 A / g;

[0052] 3. The result is as follows Figure 5 As shown, the material exhibits good rate pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific energy | aaaaa | aaaaa |

| Specific power | aaaaa | aaaaa |

| Specific power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com