A kind of preparation method and application of macrolide antibiotic hollow porous molecularly imprinted polymer

A technology of macrolides and molecular imprinting, which is applied in the field of analytical chemistry pretreatment, can solve the problems that have not yet been reported on the preparation and application of antibiotic hollow porous imprinted polymers, and achieve the goal of improving the combination of mass transfer rate and unit mass Molecular ability, high extraction recovery, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1. Preparation method of macrolide antibiotic hollow porous molecularly imprinted polymer

[0029] (1) Step 1. Synthesis of mesoporous silicon microspheres: 40.5 mmol of NH 4 Dissolve F and 2.5mmol CTAB in 250mL distilled water, heat in a water bath at 80°C, and stir at 1000rpm. After it is completely dissolved into a colorless and transparent solution, add 4.5mLTEOS dropwise, continue heating and stirring for 6 hours, and centrifuge , washing with water, washing with alcohol, and drying, the resulting product was heated to 550°C at a rate of 5°C / min in an air atmosphere, and roasted for 6 hours to obtain an MCM-41 sample;

[0030](2) Step 2, synthesis of surface-imprinted polymer: Weigh 0.25 mmol of spiramycin and dissolve it in a mixed solvent of 16 mL of acetonitrile and 4 mL of methanol, add 1 mmol of methacrylic acid, and ultrasonicate the mixed solution at room temperature to make The template molecule is fully mixed with the functional monomer; then 5 mm...

Embodiment 2

[0032] Example 2. Validation of the effect of HPMIPs on the enrichment and concentration of macrolides

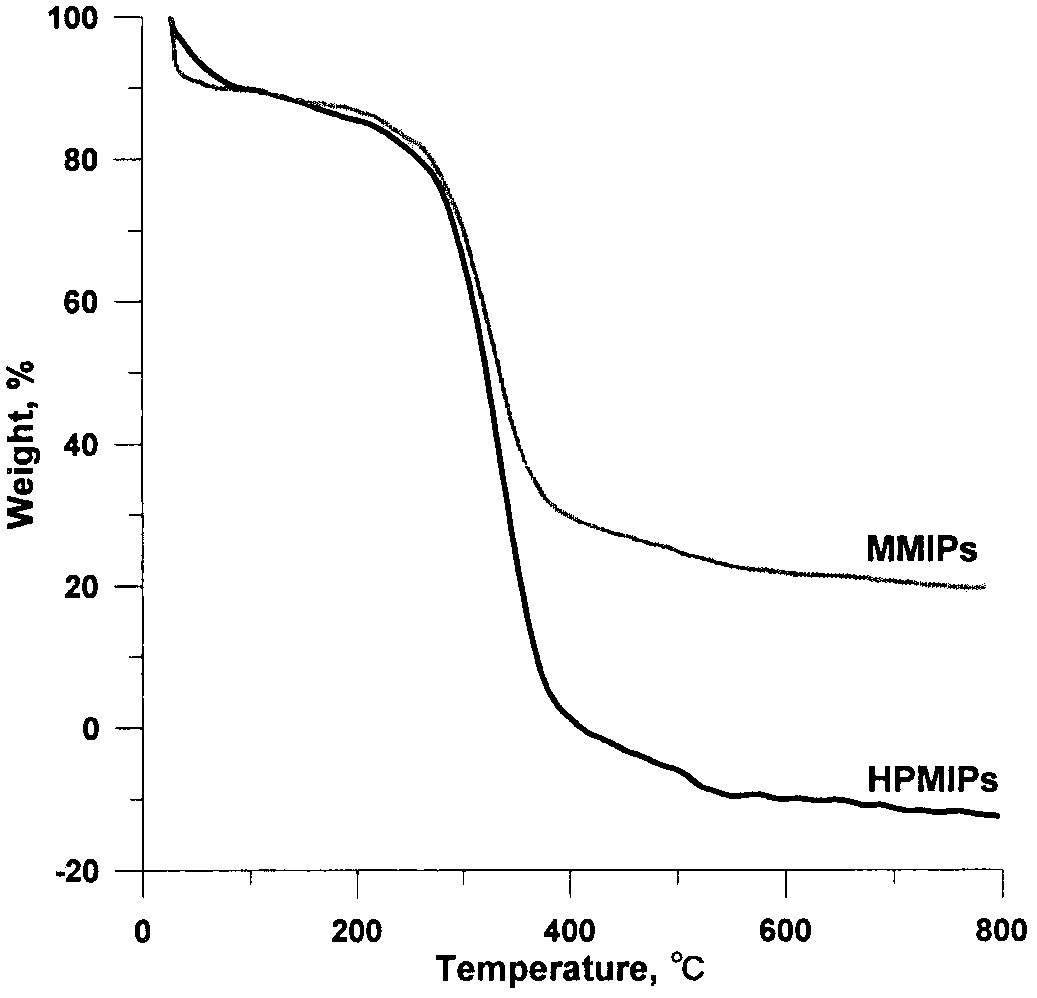

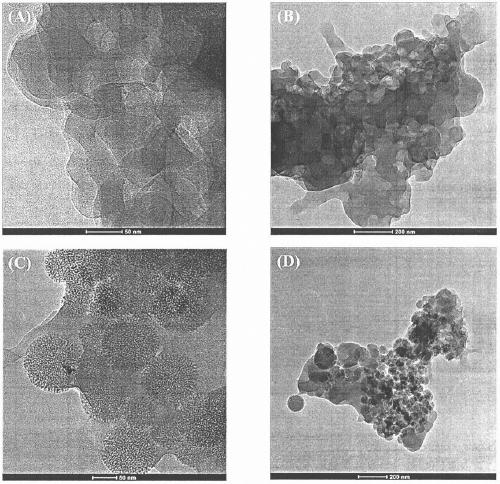

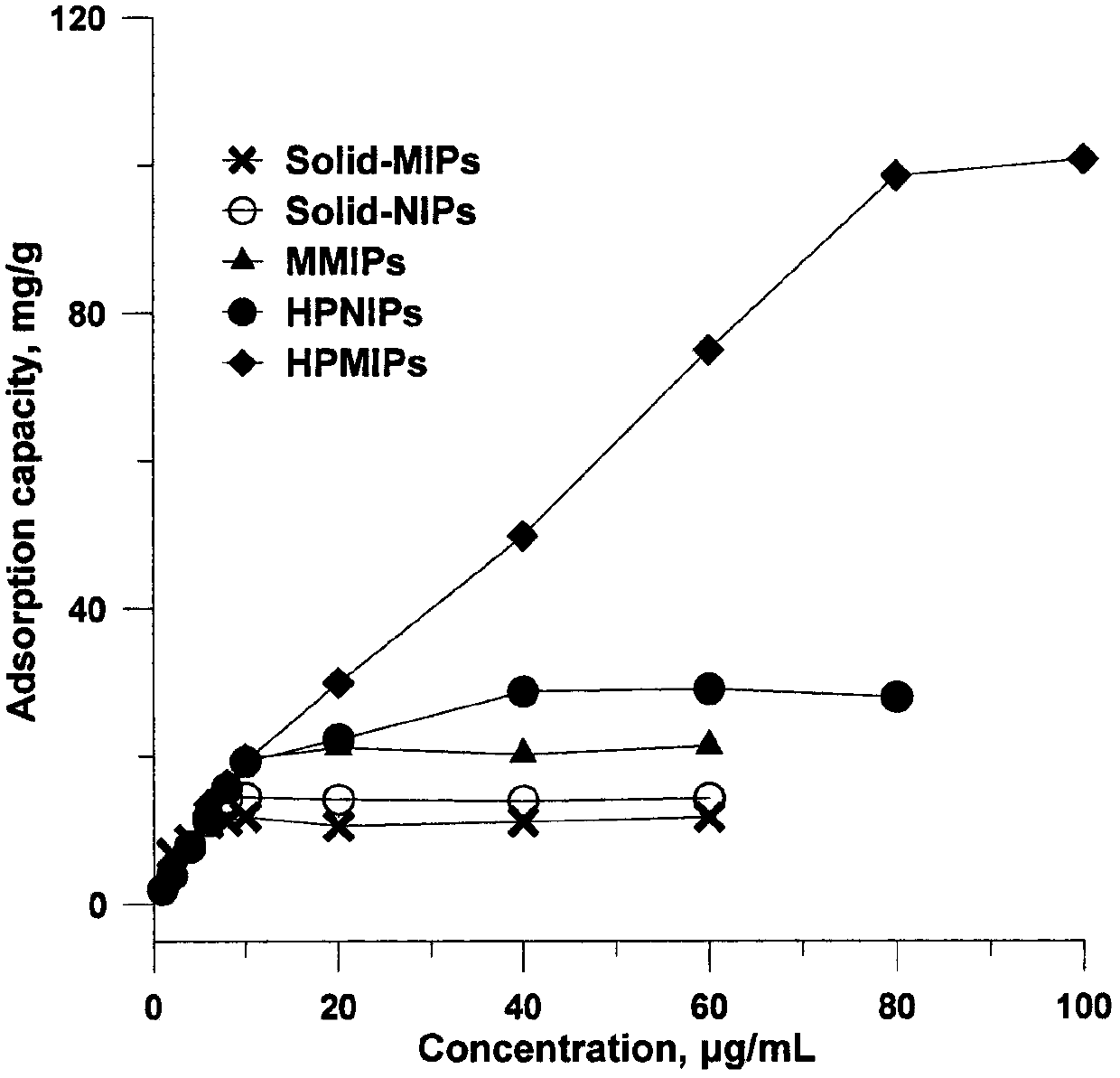

[0033] (1) The adsorption properties of molecularly imprinted polymers to template molecules were determined at different ratios, see Table 1. Finally, the optimal ratio of template molecule: functional monomer: crosslinking agent = 1:4:20 was established, and the enrichment effect was the best when the functional monomer was methacrylic acid. The resulting molecularly imprinted polymers were characterized by thermogravimetric analysis, see figure 1 . It can be seen from the thermogravimetric curve that in the range of 0 to 800 °C, the MMIPs material produces about 80% of the weight loss, and the HPMIPs material produces about 100% of the mass loss, indicating that the MCM-41 mesoporous silicon core in the obtained HPMIPs material ( About 20% by weight of MMIPs) has been completely removed.

[0034] Table 1 Optimization of the types and proportions of functional monomers...

Embodiment 3

[0040] Embodiment 3. HPMIPs material detects commercially available honey

[0041] (1) The hollow porous imprinted polymers (HPMIPs) obtained above were used as dispersive solid-phase extraction (DSPE) adsorbents. With a concentration of 20mmol / L K 2 HPO 4 Samples were loaded with buffer solution (pH=8.0), rinsed with 1.0 mL of water, and finally eluted with a mixture of HOAC / MeOH=2 / 98 (v / v), blown dry with nitrogen, and adjusted to 200 μL. The eluate was analyzed and detected by HPLC-MS / MS.

[0042] (2) Accurately weigh 2g of each blank honey sample, place it in a 15mL polypropylene plastic tube, and then add 10mL of K at a concentration of 20mmol 2 HPO 4 (Adjust the pH value to 8.0 with 6 mol / L HCl solution) buffer solution, vortex for 30s, centrifuge at 4500rpm for 10min, and use the centrifuged solution as the sample solution for solid phase extraction.

[0043] (3) Results

[0044] Such as Figure 5 Honey with a spiked concentration of 40mg / kg and seven macrolide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com