Roofing waterproof coating with high long-term water resistance and weathering resistance

A waterproof coating and performance technology, applied in fire-resistant coatings, polyether coatings, epoxy resin coatings, etc., can solve the problems of insufficient long-term water resistance and weather resistance, and it is difficult to meet the roofing environment, achieve good economic benefits, and improve long-term water resistance. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

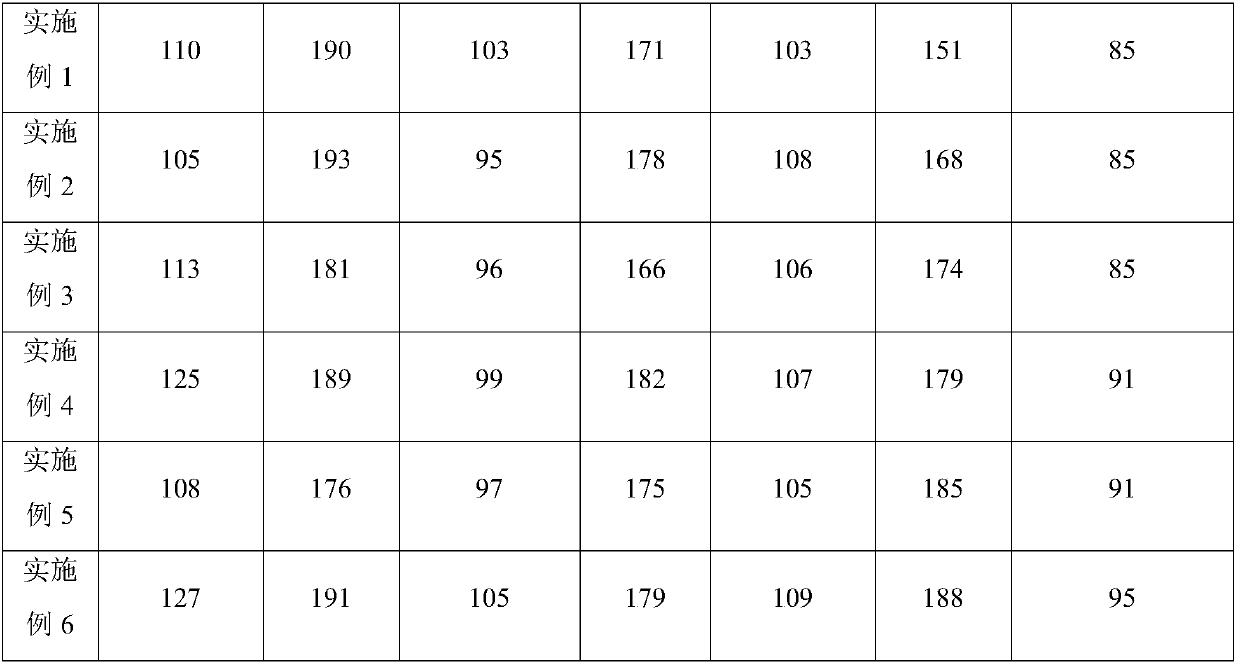

Embodiment 1

[0019] 300 parts of mixed emulsion, 300 parts of filler, 50 parts of water, 5 parts of 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 1 part of ammonium metavanadate, 5 parts of potassium hydrogen sulfate, poly 5 parts of 1,2-propanediol adipate, 2 parts of triethanolamine, 1 part of tetrabutylammonium bromide, 0.2 part of ultraviolet photoinitiator, and film-forming aids, dispersants, preservatives, defoamers, thickener.

[0020] The filler is kaolin. The mixed emulsion consists of 90 parts of pure acrylic emulsion and 5 parts of aqueous alicyclic epoxy resin emulsion in parts by weight. The alicyclic epoxy resin is 1,2 epoxy cyclohexane 4,5 diglycidyl dicarboxylate. The ultraviolet photoinitiator is diphenyl-(4-phenylthio)phenylsulfonium hexafluorophosphate.

Embodiment 2

[0022] 500 parts of mixed emulsion, 500 parts of filler, 200 parts of water, 10 parts of 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 3 parts of ammonium metavanadate, 10 parts of potassium hydrogen sulfate, poly 5-8 parts of 1,2-propanediol adipate, 5 parts of triethanolamine, 3 parts of tetrabutylammonium bromide, 3 parts of ultraviolet photoinitiator, and film-forming aids, dispersants, preservatives, defoamers agent, thickener.

[0023] The filler is kaolin. The mixed emulsion consists of 95 parts of pure acrylic emulsion and 10 parts of aqueous alicyclic epoxy resin emulsion in parts by weight. The alicyclic epoxy resin is 3,4-epoxycyclohexylmethyl methacrylate. The ultraviolet photoinitiator is diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate.

Embodiment 3

[0025] 200 parts of mixed emulsion, 400 parts of filler, 100 parts of water, 5 parts of 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 1 part of ammonium metavanadate, 5 parts of potassium hydrogen sulfate, poly 5 parts of 1,2-propanediol adipate, 2 parts of triethanolamine, 1 part of tetrabutylammonium bromide, 0.2 part of ultraviolet photoinitiator, and film-forming aids, dispersants, preservatives, defoamers, thickener.

[0026] The filler is kaolin. The mixed emulsion is composed of 90-95 parts of pure acrylic emulsion and 5-10 parts of aqueous alicyclic epoxy resin emulsion in parts by weight. The alicyclic epoxy resin is dicyclopentadiene epoxide. The ultraviolet photoinitiator is polymerized [2-hydroxyl-2-methyl-1-[4-(1-methylvinyl)phenyl]acetone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com