Anti-reflection halogen color steel plate and manufacturing method thereof

A color steel plate, anti-halogenation technology, used in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve the problems of high cost, low efficiency, low output, etc. Production cost reduction and less environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

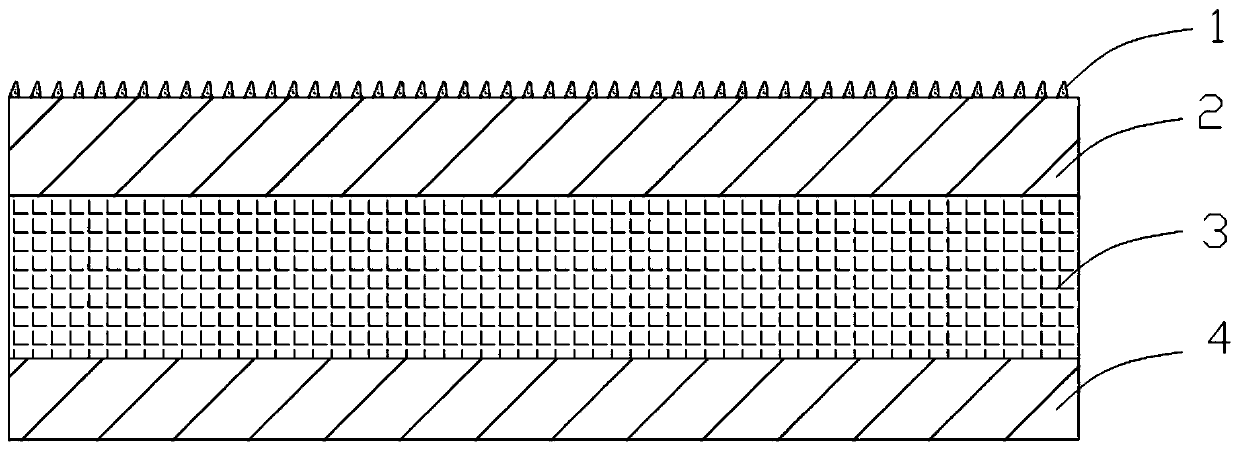

[0024] Such as figure 1 As shown, the anti-reflection halogen color steel plate includes a hydrophobic layer 1 , a back coat 2 , a substrate 3 and a top coat 4 .

[0025] The material used for the substrate 3 is galvanized steel sheet.

[0026] 1) Degrease the galvanized steel sheet with an alkaline degreasing spray agent. The main components of the spray agent are 0.1mol / L sodium hydroxide and a surfactant. The bath temperature is 50°C; the spray pressure is 2.0kg / cm2 ; The effective spraying time is 10 seconds, wash with hot water at 50°C and dry with hot air.

[0027] 2) Coating a fluorocarbon paint with a thickness of 20 μm on the upper surface of the cleaned galvanized steel sheet, and drying to obtain a top coat.

[0028] 3) At a temperature of 60° C. and 500 r / min stirring conditions, 65 wt % of polyurethane resin, 3 wt % of liquid paraffin, 12 wt % of butanone, 3 wt % of hpmc hydroxypropyl methylcellulose, 2 wt % of organically modified montmorillonite, 1wt% of modi...

Embodiment 2

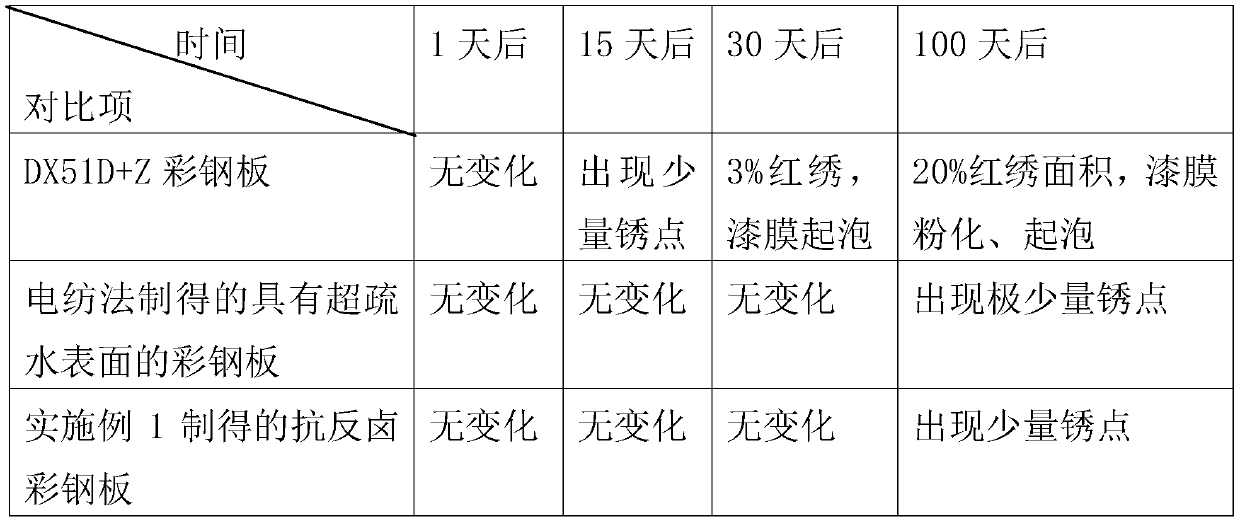

[0034] The following table is the color steel plate with super-hydrophobic surface prepared by DX51D+Z color steel plate, electrospinning method and the anti-reflection halogen color steel plate prepared in Example 1, and the anti-reflection halogen color steel plate in the present invention. On the basis of the manufacturing method, the color steel plate made in the case of a single variable; the above color steel plate is placed at an inclination angle of 20 degrees, and the surface of the hydrophobic coating is subjected to a 6h / time saturated magnesium chloride solution spray test. , 15, 30, 100 days observed corrosion resistance results.

[0035]

[0036] When the brine phenomenon occurs, the brine composition formed is mainly magnesium chloride. This experiment simulates the extreme anti-halogen phenomenon. It can be seen from the above table that the anti-halogen color steel plate made by the present invention has significantly better anti-halogen characteristics than...

Embodiment 3

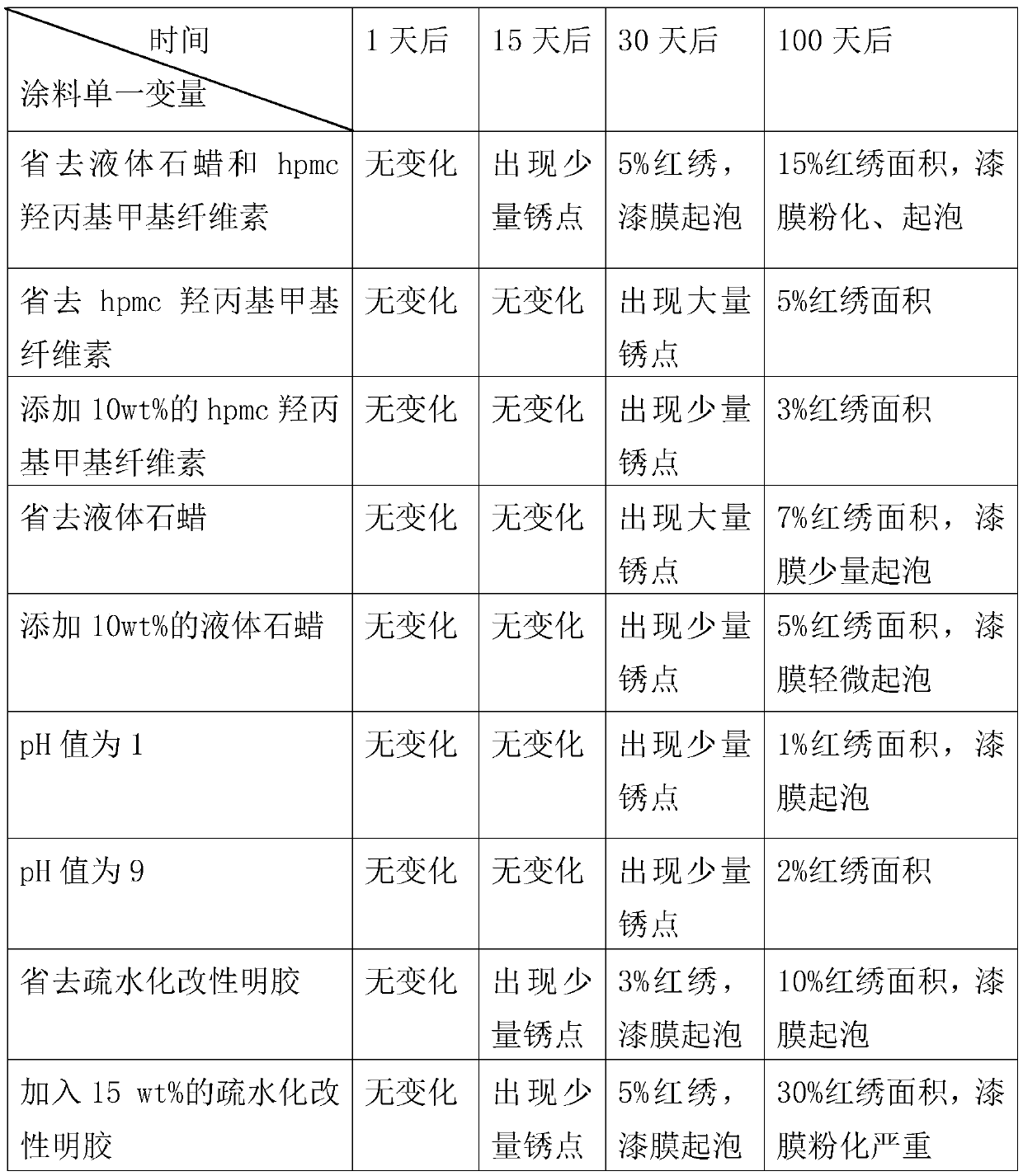

[0039] The following table is the color steel plate made by using the single variable method for the coating composition used in the back coating on the basis of the manufacturing method of the anti-halogen color steel plate of the present invention under the indoor environment; the prepared color steel plate is placed at an inclination angle of 20 degrees , the surface of its hydrophobic coating was sprayed with saturated magnesium chloride solution for 6h / time, and the corrosion resistance results were observed on the 1st, 15th, 30th, and 100th day of the experiment.

[0040]

[0041] Studies have shown that using acetic anhydride and benzyl alcohol to hydrophobize gelatin for acetylation and esterification reactions respectively, the gelatin after modification has enhanced hydrophobicity, is insoluble in water at room temperature, and the degradation rate is greatly slowed down. The sex, elasticity and plasticity are stronger than the original gelatin glue.

[0042] It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com