Electrode loading with composite oxide magnetic nanowire and carbon nanotube and its preparation and application

A composite oxide, magnetic nanotechnology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large electrode loss and high voltage of liquid phase discharge technology , to achieve the effect of improving full contact, easy control of preparation process conditions, and increasing discharge electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

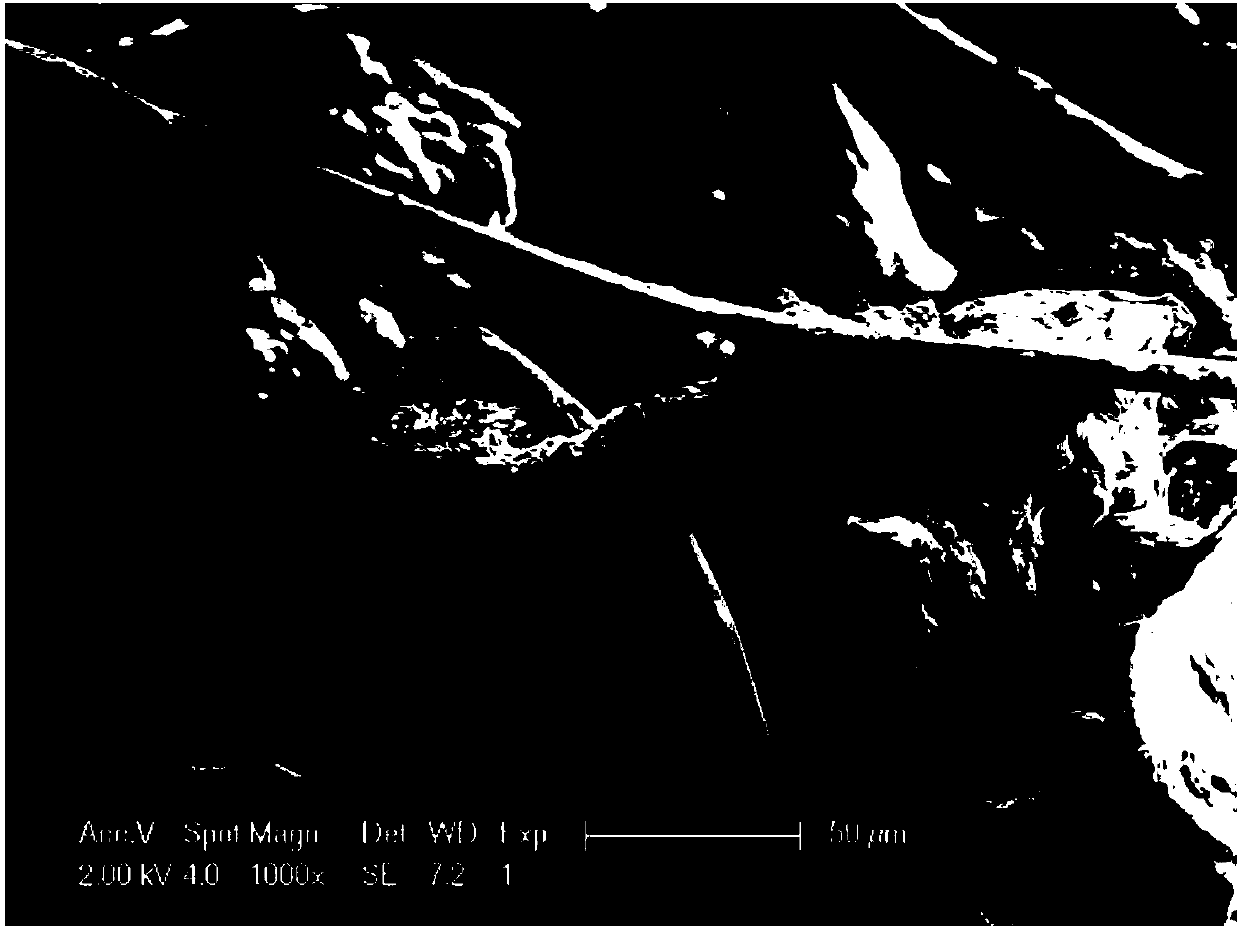

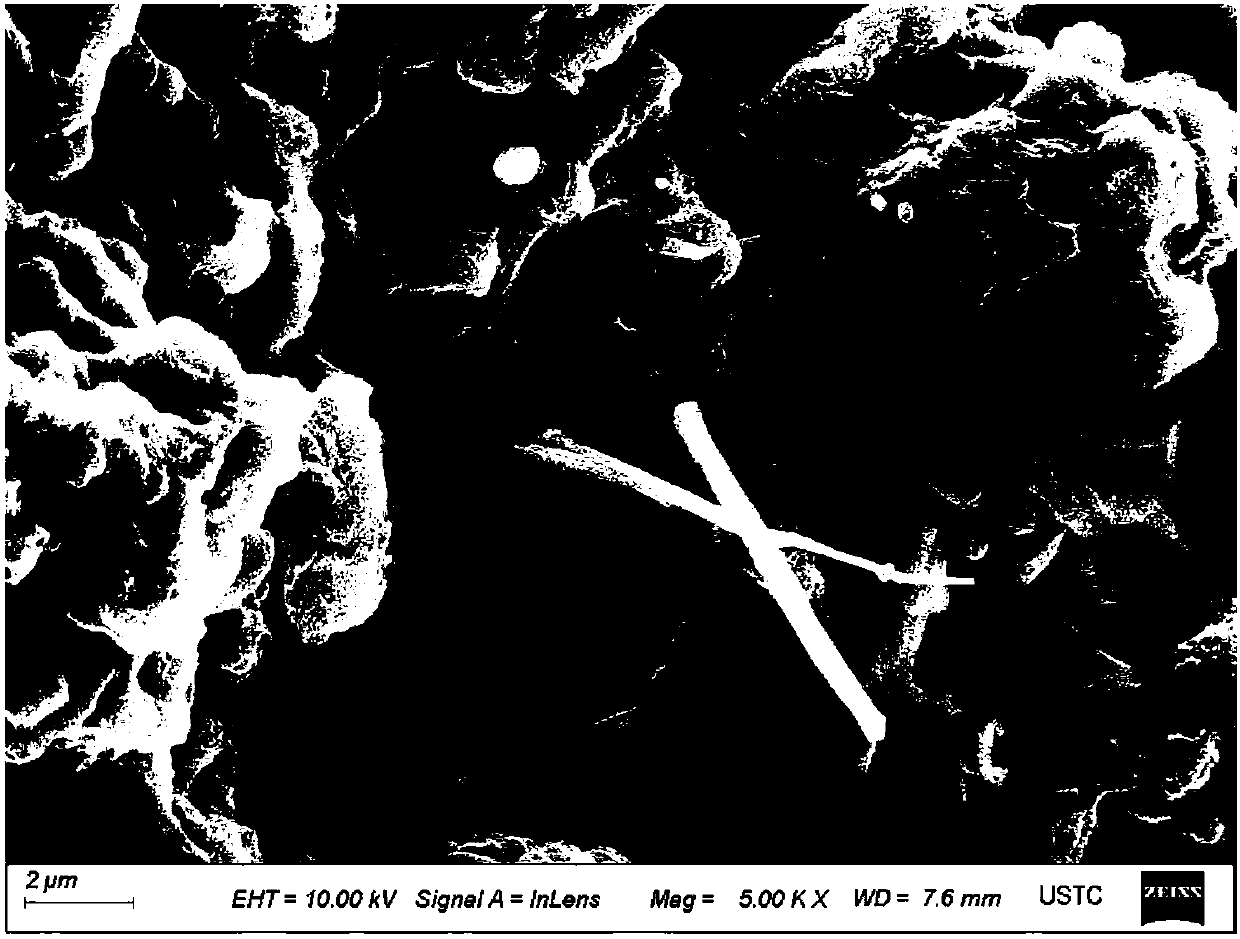

[0037] ZnCo 2 o 4 Preparation of nanowire / carbon nanotube electrodes

[0038] Mix 2.5g of cetyltrimethylammonium bromide (CTAB), 75mL of cyclohexane and 2.5mL of n-pentanol, and stir on a magnetic stirrer for 20 minutes to form. Add 3.75mL of 0.1M oxalic acid solution to the above solution system, and stir thoroughly for 30 minutes. Add 1.25ml of 0.05M Zn(NO 3 ) 2 solution and 0.1M Co(NO 3 ) 2 The mixed solution of the solution was stirred at room temperature for 24 hours, and the stirring was maintained throughout the operation. After the reaction, the obtained yellow microemulsion was centrifuged with alcohol to remove excess impurity ions, and the finally obtained sample was dried in air at 80° C. to obtain a pink powder. Separate the yellow powder in O 2 Heat treatment at 500°C for 3 hours to obtain the final product ZnCo 2 o 4 Nanowires.

[0039] Dissolve 0.01g of metal oxide, 0.4g of multi-walled carbon nanotubes and 4g of sodium dodecylbenzenesulfonate in 100...

Embodiment 2

[0041] CoFe 2 o 4 Preparation of nanowire / carbon nanotube electrodes

[0042] Mix 2.5g of cetyltrimethylammonium bromide (CTAB), 75mL of cyclohexane and 2.5mL of n-pentanol, and stir on a magnetic stirrer for 20 minutes to form. Add 3.75mL of 0.1M oxalic acid solution to the above solution system, and stir thoroughly for 30 minutes. Add 1.25ml of 0.05M Co(NO 3 ) 2 solution and 0.1M FeSO 4 solution and stirred at room temperature for 24 hours, maintaining stirring throughout the operation. After the reaction, the obtained yellow microemulsion was centrifuged with alcohol to remove excess impurity ions, and the finally obtained sample was dried in air at 80° C. to obtain a yellow powder. Separate the yellow powder in O 2 Heat treatment at 500°C for 3 hours to obtain the final product CoFe 2 o 4 Nanowires.

[0043] Dissolve 0.01g of metal oxide, 0.4g of multi-walled carbon nanotubes and 4g of sodium dodecylbenzenesulfonate in 100ml of ethylene glycol, and ultrasonicate ...

Embodiment 3

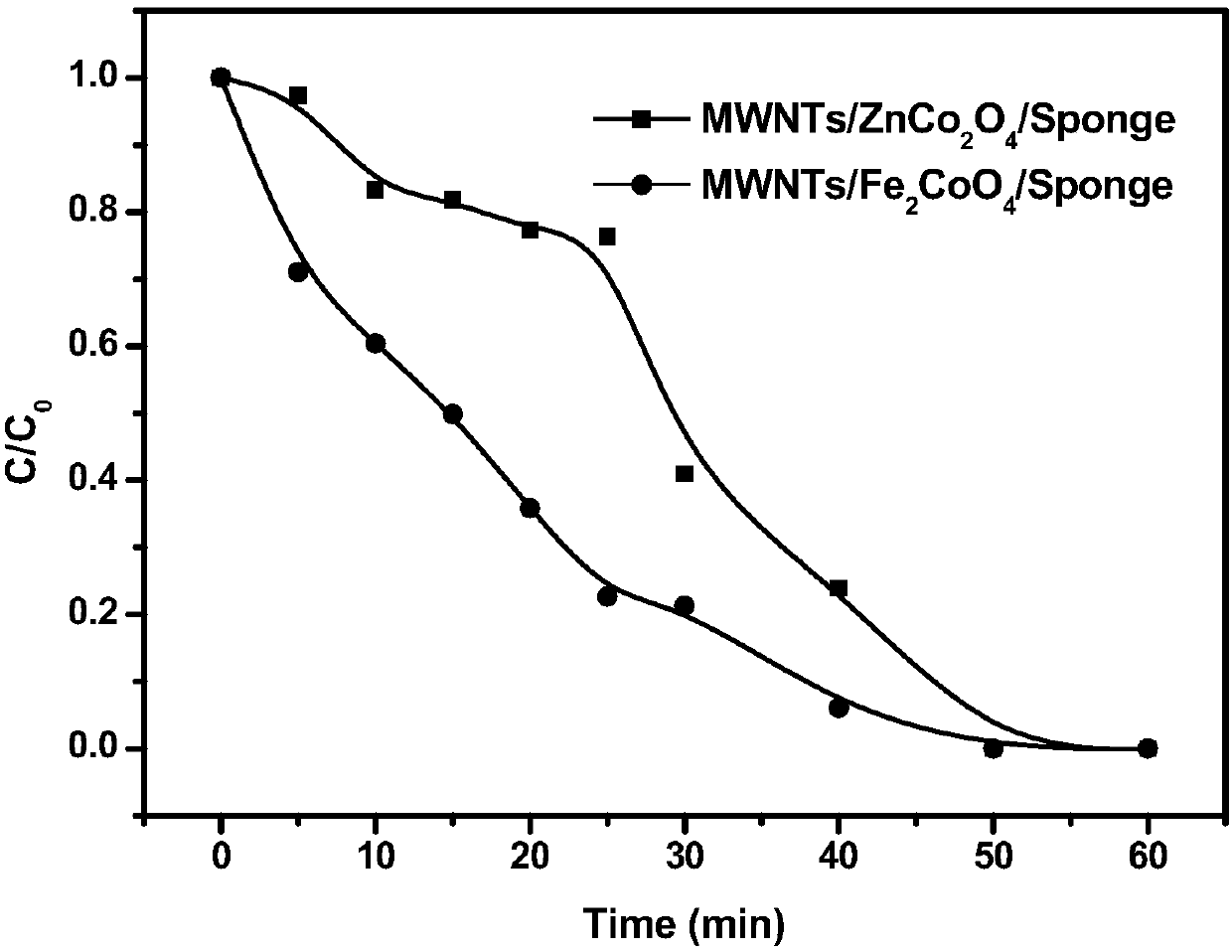

[0045] The gas-liquid interface micro-discharge experiment was carried out. Quartz glass is used as the high-voltage electrode to carry out dielectric barrier discharge, and the transition metal / cobalt composite oxide nanowire / carbon nanotube sponge electrode prepared in the embodiment (1) or (2) is used as the ground electrode, and the whole reactor is implemented Example (1) or (2) prepared electrodes. Use the compound electrode prepared by embodiment (1) or (2) to process 10mg / L phenol solution, wherein the size of the compound electrode is 6 * 7cm, add 100mL of configured phenol solution, set the distance 2mm between the electrode and the liquid surface, Close the reactor door. The reactor was turned on, and the reaction voltage was adjusted to 30V and the maximum reaction current at this voltage. The time of the phenol degradation process was set at 60 minutes, and a sample was collected every 5 minutes to 10 minutes. The sampling volume was about 1 mL. The content of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com