Molybdenum disulfide intercalated hydrotalcite composite material and preparation method and application thereof

A technology of molybdenum disulfide and composite materials, which is applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve the problems of reduction of photocatalyst active sites, deterioration of catalyst performance, and easy recombination of photogenerated carriers. , to achieve the effect of improving photocatalytic performance, more active sites, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

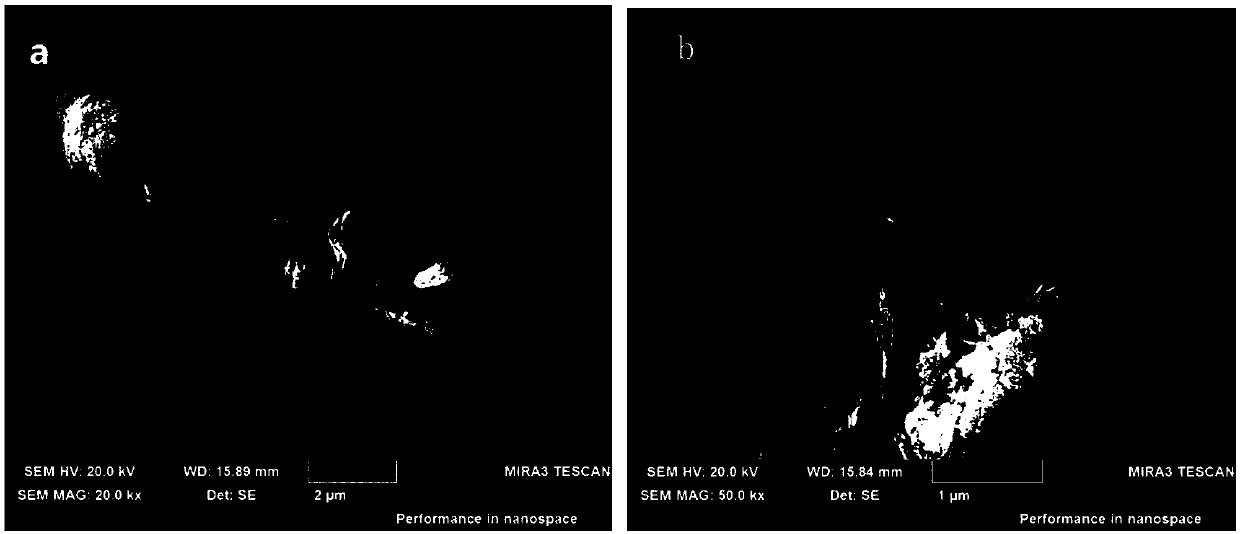

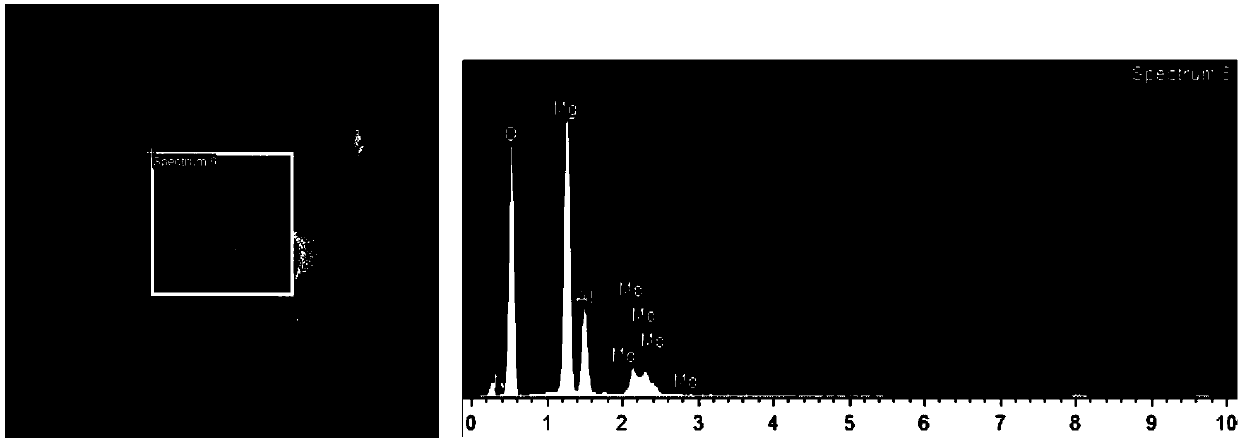

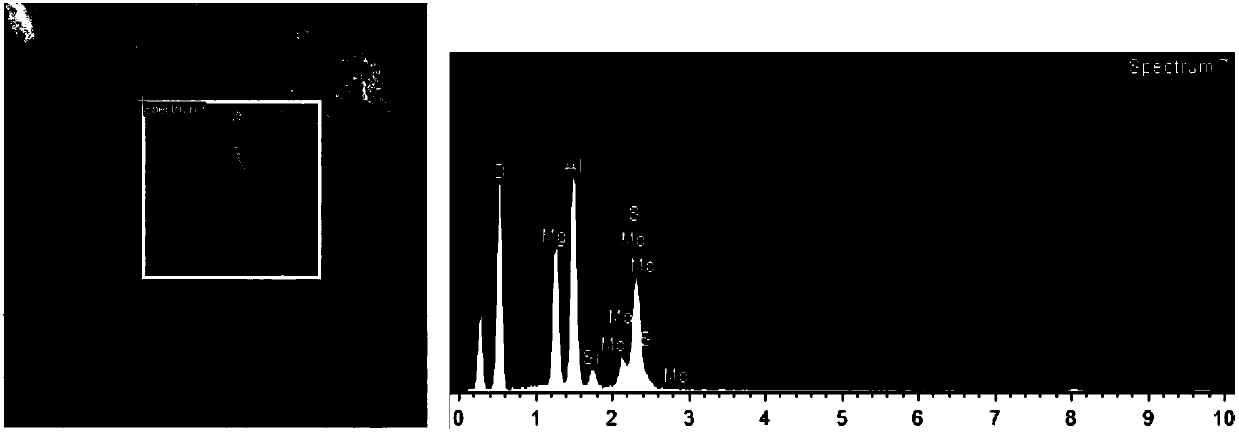

Image

Examples

Embodiment 1

[0049] A kind of preparation method of triethanolamine modified molybdenum disulfide intercalation MgAl hydrotalcite composite catalytic material of the present invention, it specifically comprises the following steps:

[0050] (1) Add 0.05mol magnesium chloride, 0.02mol aluminum nitrate, 0.04mol sodium molybdate and 0.06mol sodium hydroxide to 100mL water, stir and react at 35°C for 1h; then heat up to 85°C for 6h crystallization; crystallization is complete After suction filtration and washing, the filter cake was dispersed in 50mL water to make hydrotalcite prepolymer suspension;

[0051] (2) Take 50mL of the above-mentioned hydrotalcite prepolymer suspension, add 2.5g of thiourea and 1.5g of triethanolamine, ultrasonically disperse it, place it in a high-pressure reactor, and raise the temperature to 200°C at a heating rate of 3°C / min. ℃, heat preservation reaction for 900min, cooling after the completion of the reaction, washing with a mixed solution of water and ethanol ...

Embodiment 2

[0085] A kind of preparation method of ethylenediamine tetraethanol modified molybdenum disulfide intercalation MgFe hydrotalcite composite catalytic material of the present invention, its specific steps are as follows:

[0086] (1) Add 0.05mol magnesium chloride, 0.02mol ferric chloride, 0.04mol sodium molybdate and 0.06mol sodium hydroxide to 100mL water, stir at 35°C for 1h, then raise the temperature to 85°C for 6h, crystallization is complete After suction filtration and washing, the filter cake was dispersed in 50mL water to make hydrotalcite prepolymer suspension;

[0087] (2) Take 50mL of the above-mentioned hydrotalcite prepolymer suspension, add 2.5g of thiourea and 1.8g of ethylenediaminetetraethanol, after ultrasonic dispersion, put it in a high-pressure reactor, under the condition that the heating rate is 3°C / min Raise the temperature to 200°C, keep it warm for 900 minutes, cool down after the reaction, wash with a mixed solution of water and ethanol (50% mass fr...

Embodiment 3

[0091] A kind of preparation method of triisopropanolamine modified molybdenum disulfide intercalation ZnAl hydrotalcite composite catalytic material of the present invention, its specific steps are as follows:

[0092] (1) Add 0.05mol magnesium chloride, 0.02mol ferric chloride, 0.04mol sodium molybdate and 0.06mol sodium hydroxide to 100mL water, stir at 35°C for 1h, then raise the temperature to 85°C for 6h, crystallization is complete After suction filtration and washing, the filter cake was dispersed in 50mL water to make hydrotalcite prepolymer suspension;

[0093] (2) Take 50mL of the above-mentioned hydrotalcite prepolymer suspension, add 2.5g of thiourea and 1.8g of triisopropanolamine, after ultrasonic dispersion, put it in a high-pressure reactor, under the condition that the heating rate is 3°C / min Raise the temperature to 200°C, keep it warm for 900 minutes, cool down after the reaction, wash with a mixed solution of water and ethanol (50% by mass) for 3 to 5 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com