Method for preparing 1,4-butanediol

A technology of butanediol and diacetoxybutene is applied in the field of preparing 1,4-butanediol and can solve the problems of low yield and selectivity of 4-butanediol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

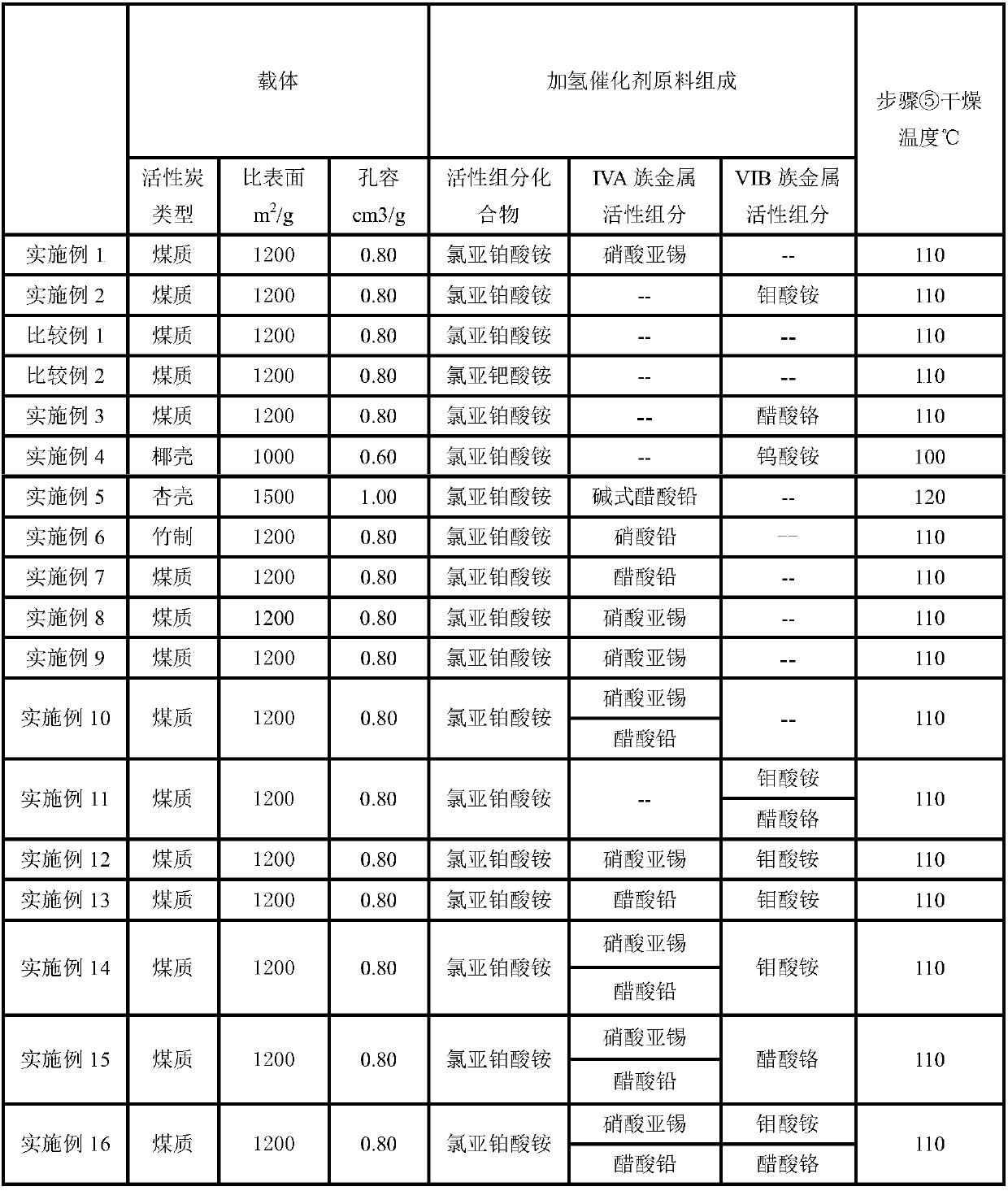

Embodiment 1

[0043] Preparation of hydrogenation catalyst:

[0044] ① Ammonium chloroplatinite ((NH 4 ) 2 PtCl 4 ) is dissolved in the hydrochloric acid aqueous solution that concentration is 8wt%, obtains impregnation solution 200ml, and 1L diameter 3mm, length 2cm, pore volume are 0.80cm 3 / g, the specific surface area is 1200cm 2 The coal-based cylindrical activated carbon carrier of / g is impregnated in the above-mentioned impregnating liquid, obtains catalyst precursor I;

[0045] ② Standing and aging for 24 hours to obtain catalyst precursor II;

[0046] ③ with a concentration of 8% (in N 2 h 4 ·H 2 The 500ml hydrazine hydrate of (2 weight ratio) reduces catalyst precursor II for 3h, obtains catalyst precursor III;

[0047] ④ washed with water to no chloride ion, dried at 50°C for 4 hours to obtain catalyst precursor IV;

[0048] ⑤Stannous nitrate (Sn(NO) containing 1.85g Sn 3 ) 2 ) 180ml of aqueous solution was impregnated on the catalyst precursor IV, and dried at 110° C...

Embodiment 2

[0054] Preparation of hydrogenation catalyst:

[0055] ① Ammonium chloroplatinite ((NH 4 ) 2 PtCl 4 ) is dissolved in the hydrochloric acid aqueous solution that concentration is 8wt%, obtains impregnation solution 200ml, and 1L diameter 3mm, length 2cm, pore volume are 0.80cm 3 / g, the specific surface area is 1200cm 2 The coal-based cylindrical activated carbon carrier of / g is impregnated in the above-mentioned impregnating liquid, obtains catalyst precursor I;

[0056] ② Standing and aging for 24 hours to obtain catalyst precursor II;

[0057] ③ with a concentration of 8% (in N 2 h 4 ·H 2 The 500ml hydrazine hydrate of (2 weight ratio) reduces catalyst precursor II for 3h, obtains catalyst precursor III;

[0058] ④ washed with water to no chloride ion, dried at 50°C for 4 hours to obtain catalyst precursor IV;

[0059] ⑤ Ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) 180ml of aqueous solution was impregnated on the catalyst precursor IV, and dried at 110° C....

Embodiment 3

[0089] Preparation of hydrogenation catalyst:

[0090] ① Ammonium chloroplatinite ((NH 4 ) 2 PtCl 4 ) is dissolved in the hydrochloric acid aqueous solution that concentration is 8wt%, obtains impregnation solution 200ml, and 1L diameter 3mm, length 2cm, pore volume are 0.80cm 3 / g, the specific surface area is 1200cm 2 The coal-based cylindrical activated carbon carrier of / g is impregnated in the above-mentioned impregnating liquid, obtains catalyst precursor I;

[0091] ② Standing and aging for 24 hours to obtain catalyst precursor II;

[0092] ③ with a concentration of 8% (in N 2 h 4 ·H 2 The 500ml hydrazine hydrate of (2 weight ratio) reduces catalyst precursor II for 3h, obtains catalyst precursor III;

[0093] ④ washed with water to no chloride ion, dried at 50°C for 4 hours to obtain catalyst precursor IV;

[0094] ⑤ Chromium acetate (Cr(OAc) containing 1.85g Cr 3 ·6H 2 O) Dissolved in hot water to obtain 180 ml of impregnating solution, impregnated on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com