Spherical nickel cobalt aluminum precursor and preparation method therefor

A spherical nickel-cobalt-aluminum precursor technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problem of affecting the electrochemical performance of nickel-cobalt-aluminum materials, unfavorable electrolyte full contact, and uneven primary particle morphology And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing the spherical nickel-cobalt-aluminum precursor described in the above technical solution, comprising the following steps:

[0025] (1) Adding the nickel-cobalt salt mixed solution and the ammonium oxalate solution into water synchronously to obtain a spherical oxalate precursor solution, and adjusting the pH value of the reaction system to 8.0-8.5 with concentrated ammonia water;

[0026] (2) adding the aluminum salt solution and the strong alkali solution into the spherical oxalate precursor solution obtained in the step (1), and reacting to obtain a spherical nickel-cobalt-aluminum precursor.

[0027] The present invention preferably provides nickel-cobalt salt solution, aluminum salt solution, strong alkali solution and ammonium oxalate solution respectively. In the present invention, the total concentration of nickel-cobalt ions in the nickel-cobalt salt mixed solution is preferably 1.0-2.0 mol / L, more prefe...

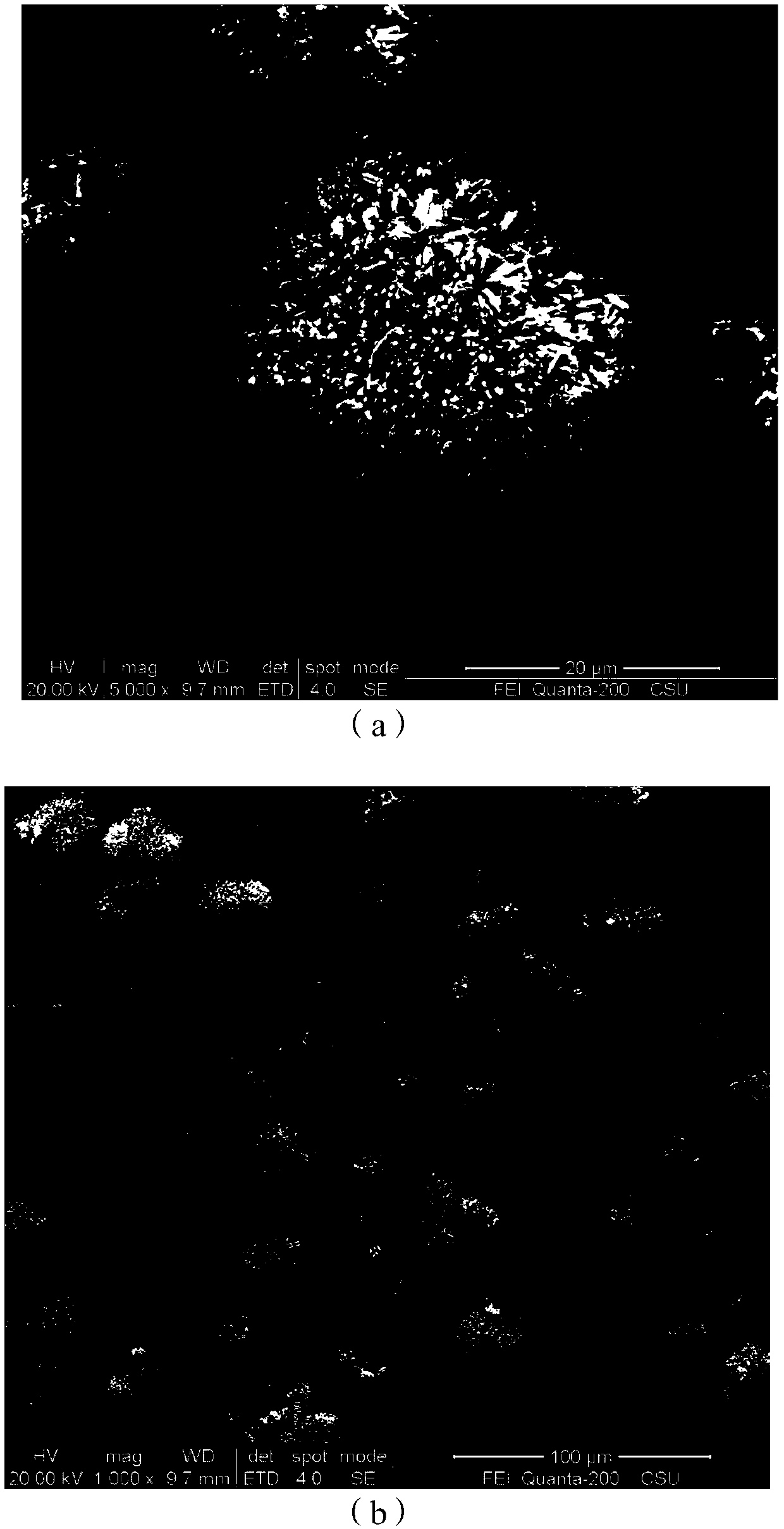

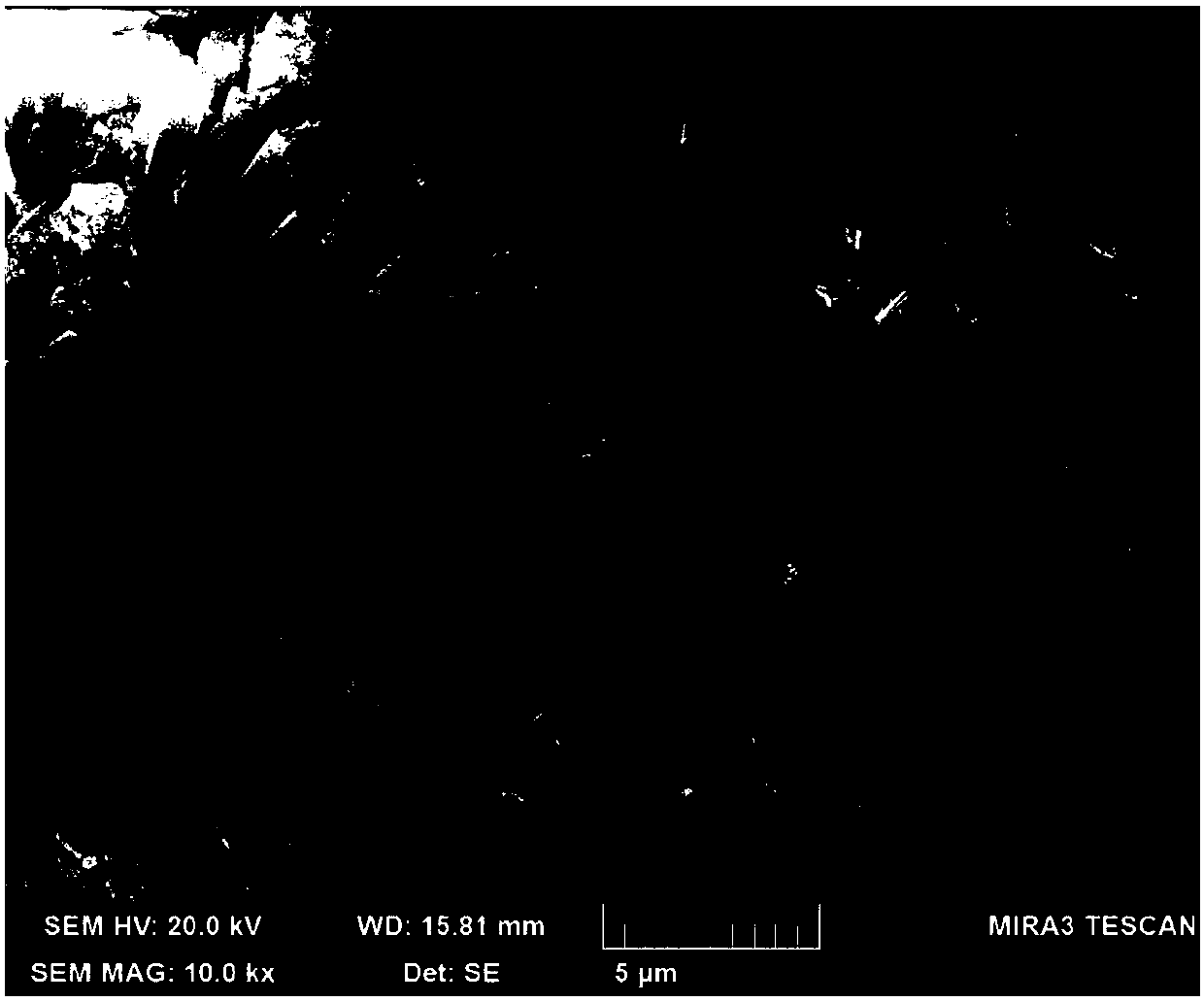

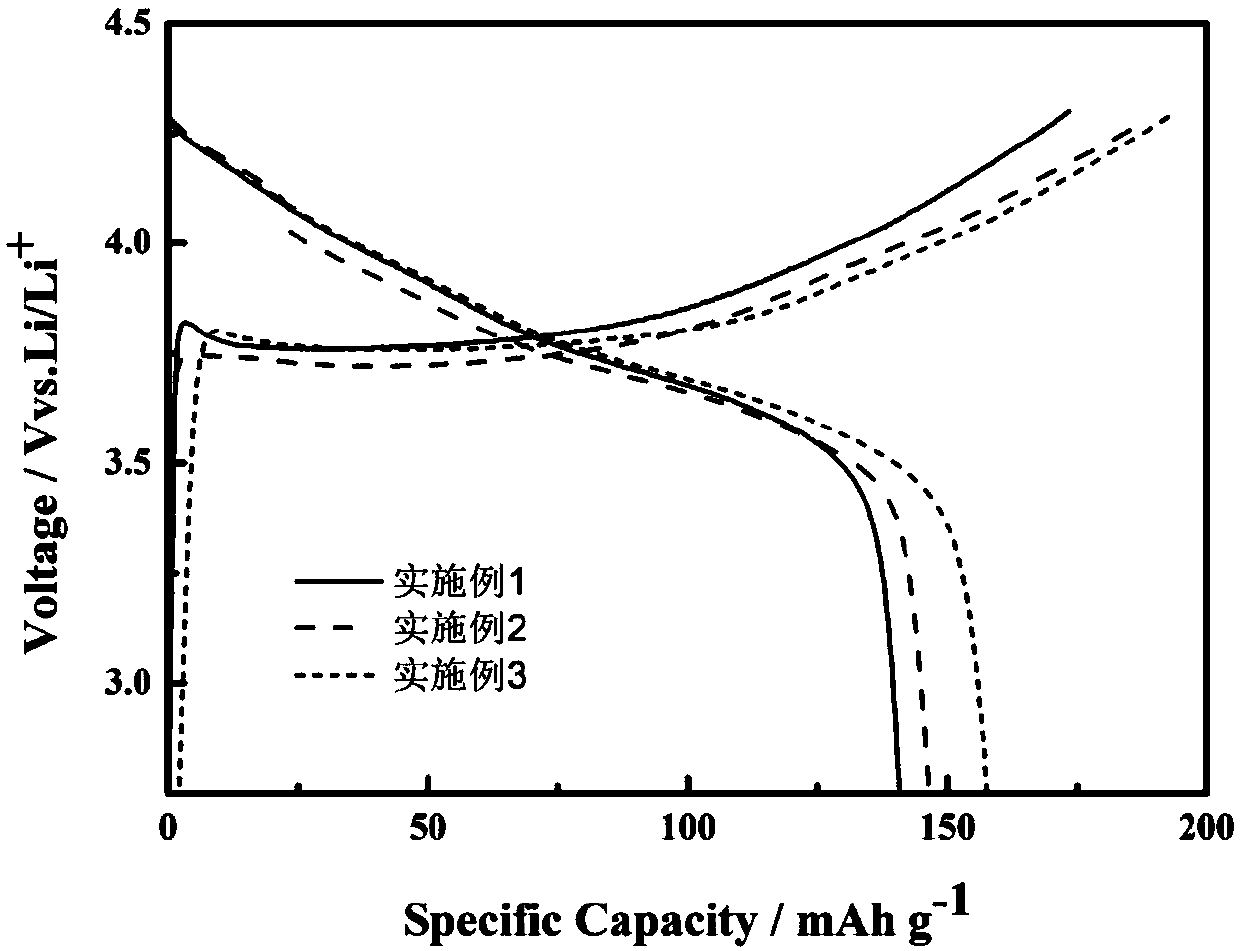

Embodiment 1

[0061] Weigh nickel sulfate, cobalt sulfate, and aluminum nitrate crystals sequentially with a molar ratio of 81.5:15:3.5, and dissolve nickel sulfate and cobalt sulfate in deionized water to obtain a uniform nickel-cobalt salt mixed solution with a volume of 100ml. The concentration is 1M, aluminum nitrate crystals are dissolved in 20ml of deionized water to obtain a 0.0175M solution, and the molar ratio of ammonium oxalate to metal is 1:1, and ammonium oxalate crystals are weighed to prepare a 0.3M solution.

[0062]Measure 1.4L of deionized water into a 3L reaction vessel, then raise the reaction temperature to 60°C, and add 1M nickel and cobalt salt mixed solution and 0.3M ammonium oxalate solution in parallel under constant temperature and continuous stirring. The feeding speed was 0.5ml / min and 1.5ml / min in turn, and during the whole feeding process, the pH value of the system was maintained at 8.0 by using concentrated ammonia water.

[0063] After the ammonium oxalate ...

Embodiment 2

[0066] Weigh nickel sulfate, cobalt sulfate, and aluminum nitrate crystals sequentially with a molar ratio of 81.5:15:3.5, and dissolve nickel sulfate and cobalt sulfate in deionized water to obtain a uniform nickel and cobalt salt mixed solution with a volume of 50ml. The concentration of aluminum nitrate is 2M, aluminum nitrate crystals are dissolved in 20ml of deionized water to obtain a 0.0175M solution, and the molar ratio of ammonium oxalate to metal is 1:1, and ammonium oxalate crystals are weighed to prepare a 0.3M solution.

[0067] Measure 1L of deionized water into a 3L reaction vessel, then raise the temperature of the reaction conditions to 60°C, add 2M mixed solution of nickel and cobalt salts and 0.3M ammonium oxalate solution in parallel under constant temperature and continuous stirring conditions, and proceed The feeding speed was 1.0ml / min and 3.0ml / min in turn, and during the whole feeding process, the pH value of the system was maintained at 8.0 by using co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com