A kind of micro-arc oxidation composite water-based fireproof coating and its preparation method

A technology of micro-arc oxidation and fireproof coating, which is applied in the direction of fireproof coatings, coatings, and devices for coating liquid on the surface. It can solve the problems of few researches on fire protection, achieve low production costs, high expansion ratio The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

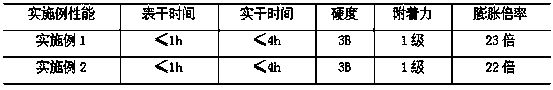

Embodiment 1

[0020] The base material is 6063 aluminum alloy; the composition of the electrolyte used in the micro-arc oxidation method is: 10g / L Na 2 SiO 3 , 10g / LNa 3 PO 4 , 5g / L (NaPO 3 ) 6 , 2g / L NaF, the solvent is deionized water; water-based fire retardant coating component content (by weight): 35 parts of water; 20 parts of base material, 25 parts of dehydration carbon-forming catalyst, 15 parts of char-forming agent, foaming 15 parts of additives, 8 parts of pigments and fillers, 1 part of additives, and 0.01 parts of graphene oxide.

[0021] Preparation of the micro-arc oxidation film layer: polish the 6063 aluminum alloy plate until the surface is smooth and smooth, then ultrasonically clean it with acetone for 5 minutes, then put it into the electrolyte, use the aluminum alloy as the anode, and stainless steel as the cathode; the micro-arc oxidation parameter setting: the frequency is 500Hz , the micro-arc oxidation reaction is carried out under the conditions that the mic...

Embodiment 2

[0029] The base material is 6063 aluminum alloy; the composition of the electrolyte used in the micro-arc oxidation method is: 10g / L Na 2 SiO 3 , 10g / LNa 3 PO 4 , 5g / L (NaPO 3 ) 6 , 2g / L NaF, the solvent is deionized water. Component content of water-based fireproof coating (by weight): 25 parts of water; 30 parts of base material, 25 parts of dehydration carbon-forming catalyst, 11 parts of char-forming agent, 12 parts of foaming agent, 5 parts of pigment and filler, and 0.8 parts of auxiliary agent part, 0.001 part of graphene oxide.

[0030] Preparation of the micro-arc oxidation film layer: polish the 6063 aluminum alloy plate until the surface is smooth and smooth, then ultrasonically clean it with acetone for 5 minutes, then put it into the electrolyte, use the aluminum alloy as the anode, and stainless steel as the cathode; the micro-arc oxidation parameter setting: the frequency is 500Hz , the micro-arc time is 30min, the duty ratio is 10%, the voltage is 480V, t...

Embodiment 3

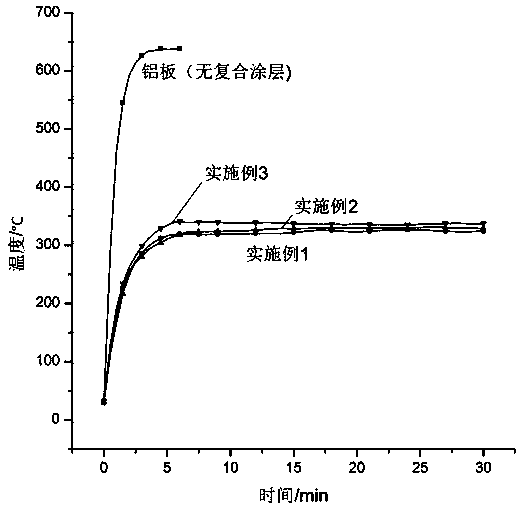

[0038] In order to compare the fire and heat insulation performance of the micro-arc oxidation composite water-based fireproof coating prepared by the present invention and a single water-based fireproof coating, the present embodiment 3 did not carry out micro-arc oxidation on the aluminum alloy in advance, but directly applied the water-based fireproof coating with brush The coating method is applied on the aluminum alloy substrate, and a single water-based fireproof coating is prepared after drying; the composition of the water-based fireproof coating is the same as that of the preparation method and Example 2, which is used as a comparison.

[0039] Refer to the requirements of the national standard GB / T15442.2-1995 "Fireproof Performance Classification and Test Method of Facing Fireproof Coatings Large Slab Fuel Method", simulate the large slab combustion method, carry out the combustion test on the prepared samples, and record the test time. The temperature change curve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com