Novel high-performance sunlight shielding coating and related adhesive and sunlight shielding membrane and base material

A high-performance technology for shading coatings, applied in the fields of solar shading coatings, adhesives, solar shading films and substrates, and new high-performance solar shading coatings. It can solve problems such as poor productivity, large shrinkage, and weak film strength. , to achieve high near-infrared shielding rate and ultraviolet shielding rate, suitable for large-scale production and application, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

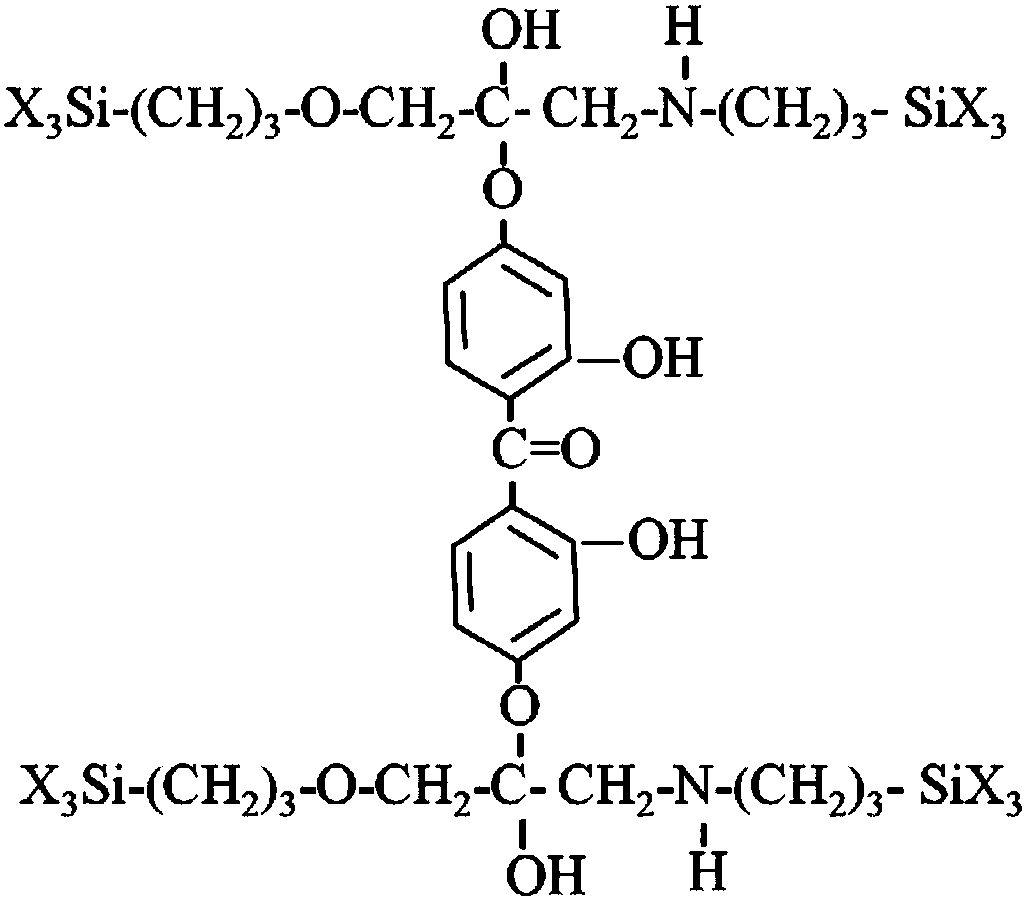

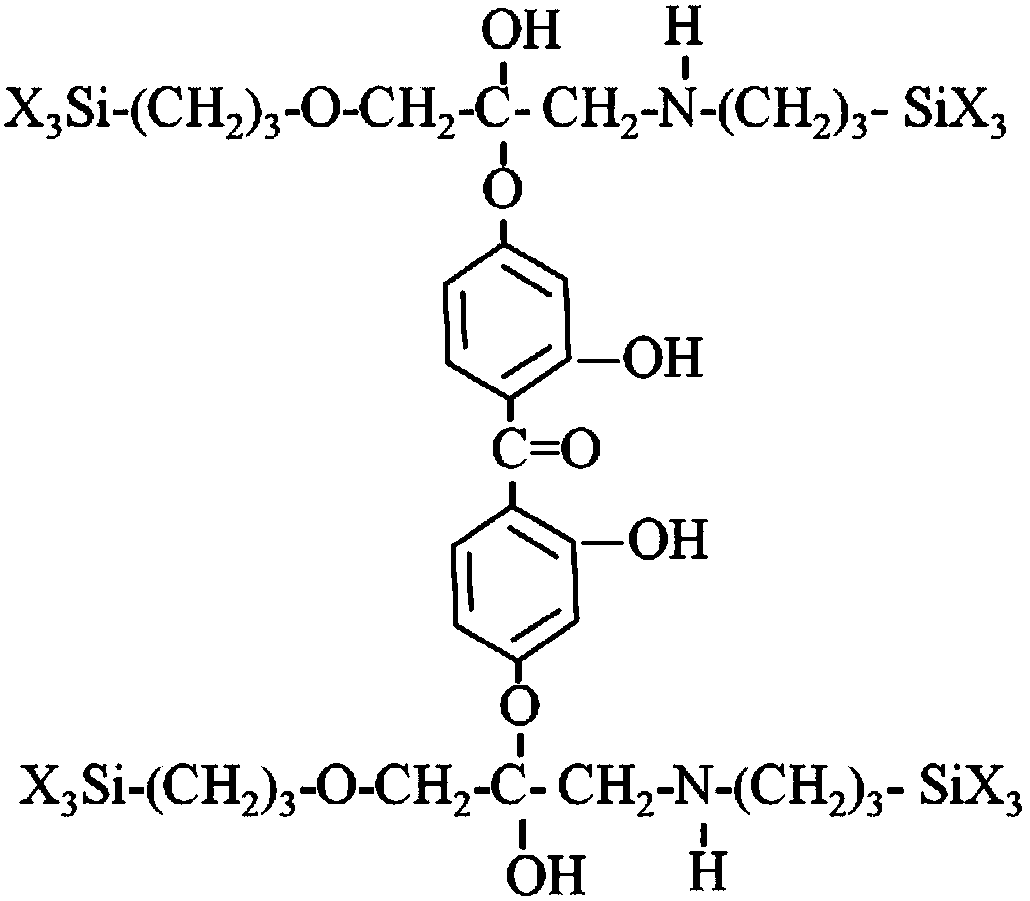

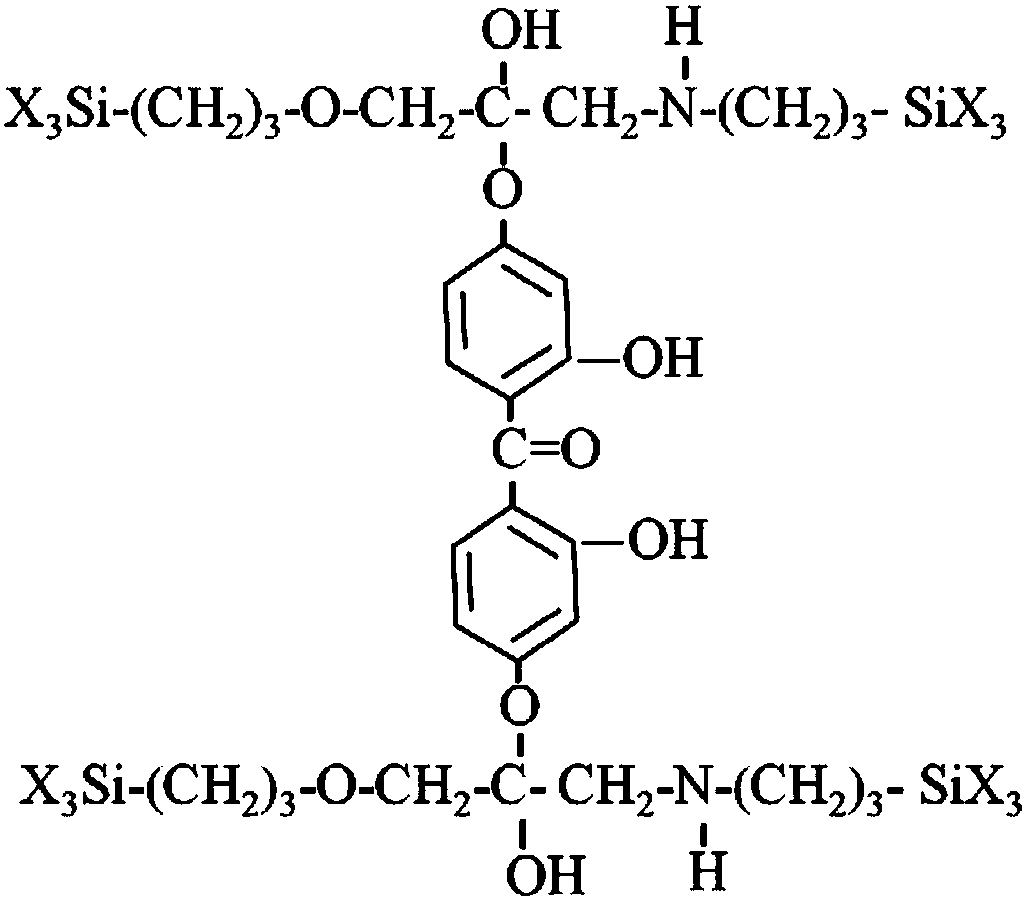

Embodiment 1

[0058] Multi-component doped tin oxide microparticles (average particle diameter 30nm) 15g, N-methyl-2-pyrrolidone (NMP) 23g, diacetone alcohol (DAA) 14g, methyl ethyl ketone 47.5g, and titanate series 0.5 g of the joint agent was mixed, and ball mill mixing was performed for 100 hours using zirconia balls with a diameter of 4 mm to prepare 100 g of a multi-component doped tin oxide dispersion (A liquid). Mix 600g of glycidyloxypropyltrimethoxysilane, 400g of aminopropyltriethoxysilane and 10g of hydroxybenzophenone, and use a magnetic stirrer in an oil bath at 60°C at a speed of 30-50rpm After stirring for 16 hours, it was aged at 60°C for 48 hours to obtain 1010 g of the target binder (synthetic liquid 1). 25 g of synthetic liquid 1, 38 g of isobutanol, 25 g of propylene glycol monoethyl ether, and 2 g of liquid A were mixed and stirred to prepare a coating material for forming a sunlight shielding film. This coating material for solar shielding film formation was apply|coa...

Embodiment 2

[0062] 15g of cesium tungsten bronze (CsxWO3) microparticles (average particle diameter 30nm), 23g of N-methyl-2-pyrrolidone, 14g of diacetone alcohol, 47.5g of methyl ethyl ketone, and 0.5g of titanate coupling agent The mixture was mixed, and ball mill mixing was performed for 100 hours using zirconia balls with a diameter of 4 mm to prepare 100 g of a dispersion liquid of cesium tungsten bronze (B liquid). 25 g of synthetic liquid 1, 14.7 g of B liquid, 23.3 g of isobutanol, 25 g of propylene glycol monoethyl ether, and 2 g of A liquid were mixed and stirred to prepare a coating material for forming a sunlight shielding film. Next, a sunlight shielding film was formed by the same procedure as in Example 1, and evaluation of the film was performed.

Embodiment 3

[0064] Antimony tin oxide (ATO) microparticles (average particle diameter 30nm) 15g, N-methyl-2-pyrrolidone 23g, diacetone alcohol 14g, methyl ethyl ketone 47.5g, and titanate-based coupling agent 0.5g The mixture was mixed, and ball mill mixing was performed for 100 hours using zirconia balls with a diameter of 4 mm to prepare 100 g of a dispersion liquid of antimony tin oxide (liquid C). 25 g of synthetic liquid 1, 38 g of isobutanol, 25 g of propylene glycol monoethyl ether, and 2 g of liquid C were mixed and stirred to prepare a coating liquid for forming a sunlight shielding film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com