Hyperbranched polymer-modified polymer film, and production method and application thereof

A technology of hyperbranched polymers and polymer membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of uncontrollable hydrophilic modification and easy contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

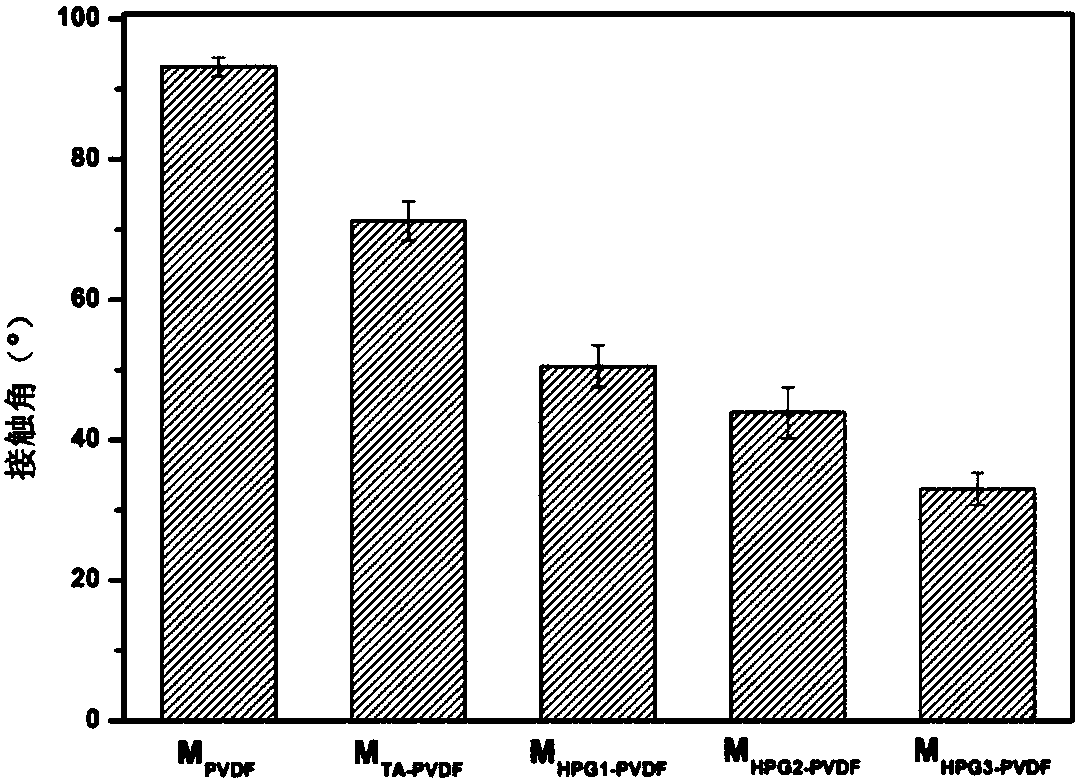

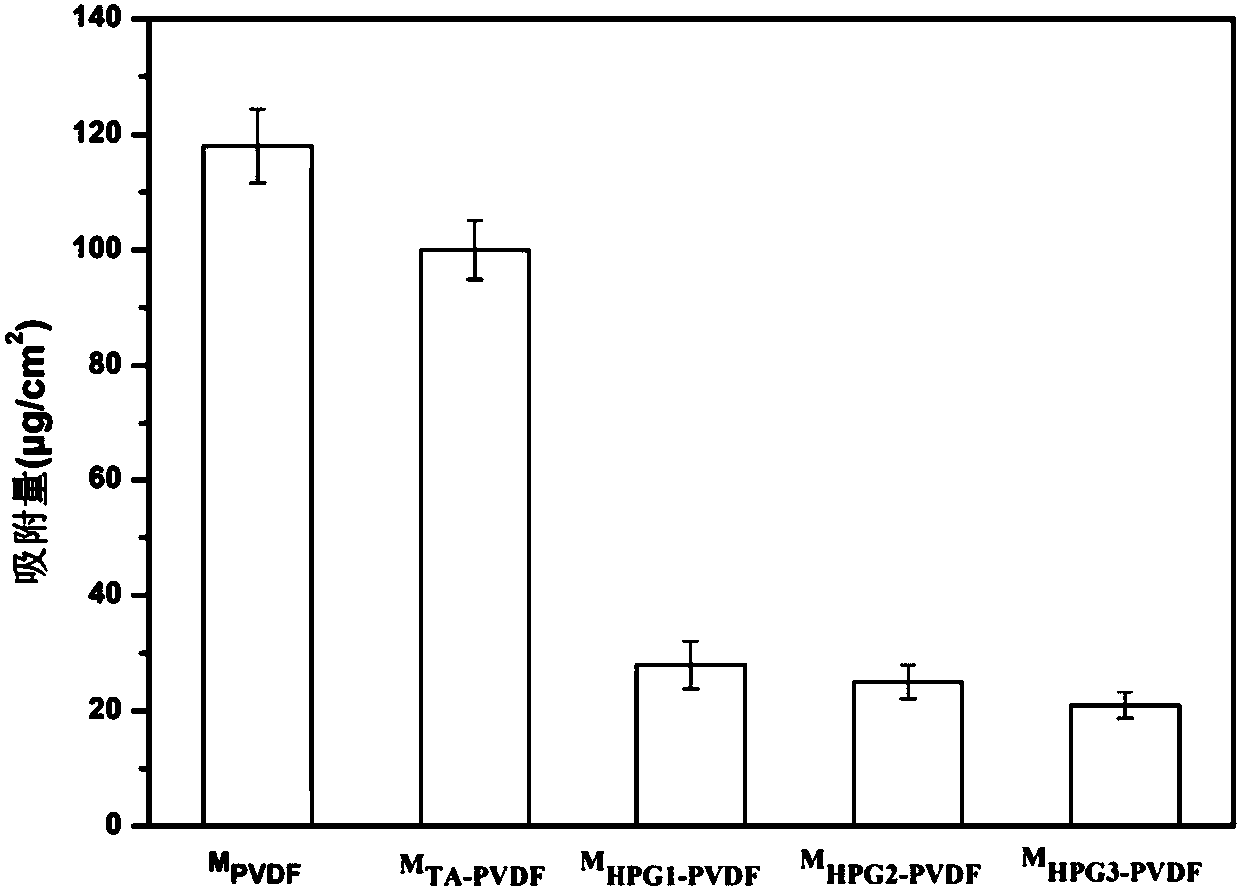

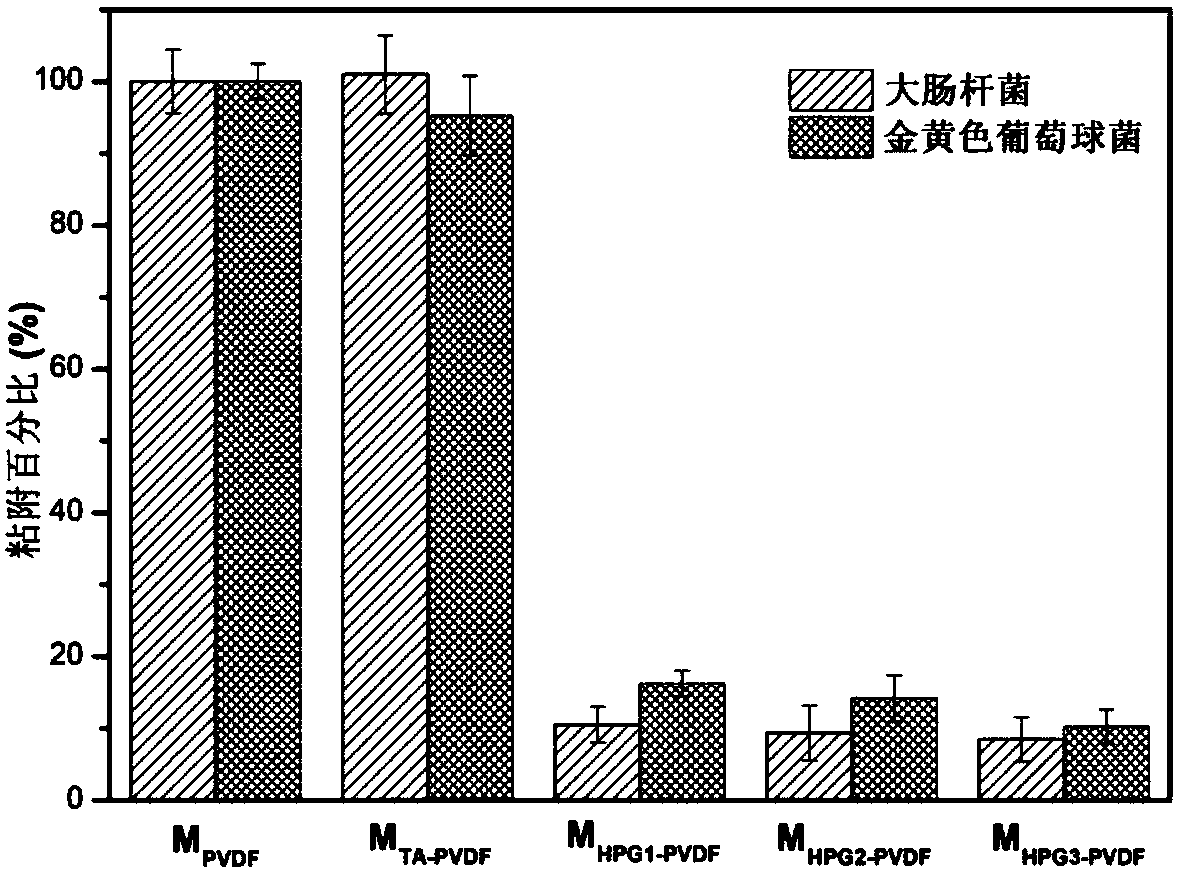

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation of embodiment 1 hyperbranched polymer modified polymer film

[0063] The polymer film selected in this embodiment is a polyvinylidene fluoride film.

[0064] (1) Initiator Bn 2 -The synthesis of Tris includes the following steps: adding Tris to the polar solvent N,N-dimethylformamide (DMF), stirring at 50°C for 1.5h to obtain a mixture A, the ratio of DMF to Tris is 150mL: 5g; Add sodium carbonate to the mixed solution A, adjust the pH of the system to 8, and continue to stir for 1.5 hours to obtain the mixed solution B; add benzyl bromide to the mixed solution B, reflux at 140°C for 24 hours, and wait for the reaction system to cool to room temperature , filter, and remove the sodium carbonate solid to obtain a mixed solution C, the mass ratio of benzyl bromide to Tris is 17:5.5; the mixed solution C is placed in a vacuum distillation device, and the DMF solvent is assisted in a vacuum oven at 85°C to obtain Bn 2 - Crude Tris; Bn dissolved in chlorofo...

Embodiment 2

[0076] The preparation of embodiment 2 hyperbranched polymer modified polymer film

[0077] The polymer film selected in this embodiment is polytetrafluoroethylene film.

[0078] (1) Initiator Bn 2 -The synthesis of Tris comprises the following steps: adding Tris to a polar solvent, stirring at 40° C. for 2 h to obtain a mixed solution A, the ratio of the polar solvent to Tris is 100 mL: 3 g; adding sodium carbonate to the mixed solution A, Adjust the pH of the system to 7, continue to stir for 2 hours to obtain a mixed solution B; add benzyl bromide to the mixed solution B, and reflux the reaction at 120°C for 30 hours. After the reaction system is cooled to room temperature, filter to remove the sodium carbonate solid to obtain a mixed solution Solution C, the mass ratio of benzyl bromide to Tris is 14:3; the mixed solution C is placed in a vacuum distillation device, and the DMF solvent is assisted in a vacuum oven at 80°C to obtain Bn 2 - Crude Tris; Bn dissolved in chlo...

Embodiment 3

[0090] The preparation of embodiment 3 hyperbranched polymer modified polymer film

[0091] The polymer membrane selected in this example is a polysulfone membrane; the plant polyphenols are a mixture of tea polyphenols and grape seed polyphenols at a mass ratio of 1:1.

[0092] (1) Initiator Bn 2 -The synthesis of Tris comprises the following steps: adding Tris to a polar solvent, stirring at 60° C. for 1 h to obtain a mixed solution A, the ratio of the polar solvent to Tris is 200 mL: 8 g; adding strong bicarbonate to the mixed solution A Potassium, adjust the pH of the system to 9, and continue to stir for 1 hour to obtain a mixed solution B; add benzyl bromide to the mixed solution B, and reflux at 160°C for 18 hours. After the reaction system is cooled to room temperature, filter to remove the potassium bicarbonate solid , to obtain a mixed solution C, the mass ratio of benzyl bromide to Tris is 20:8; the mixed solution C is placed in a vacuum distillation device, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com