Sr2FeTaO6/alumina composite catalyst for denitrification of flue gas and preparation method thereof

A composite catalyst and alumina technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of poor thermal conductivity of honeycomb cordierite and catalyst high temperature resistance Poor performance, short residence time and other problems, to achieve the effect of easy control of the preparation process, high catalytic activity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

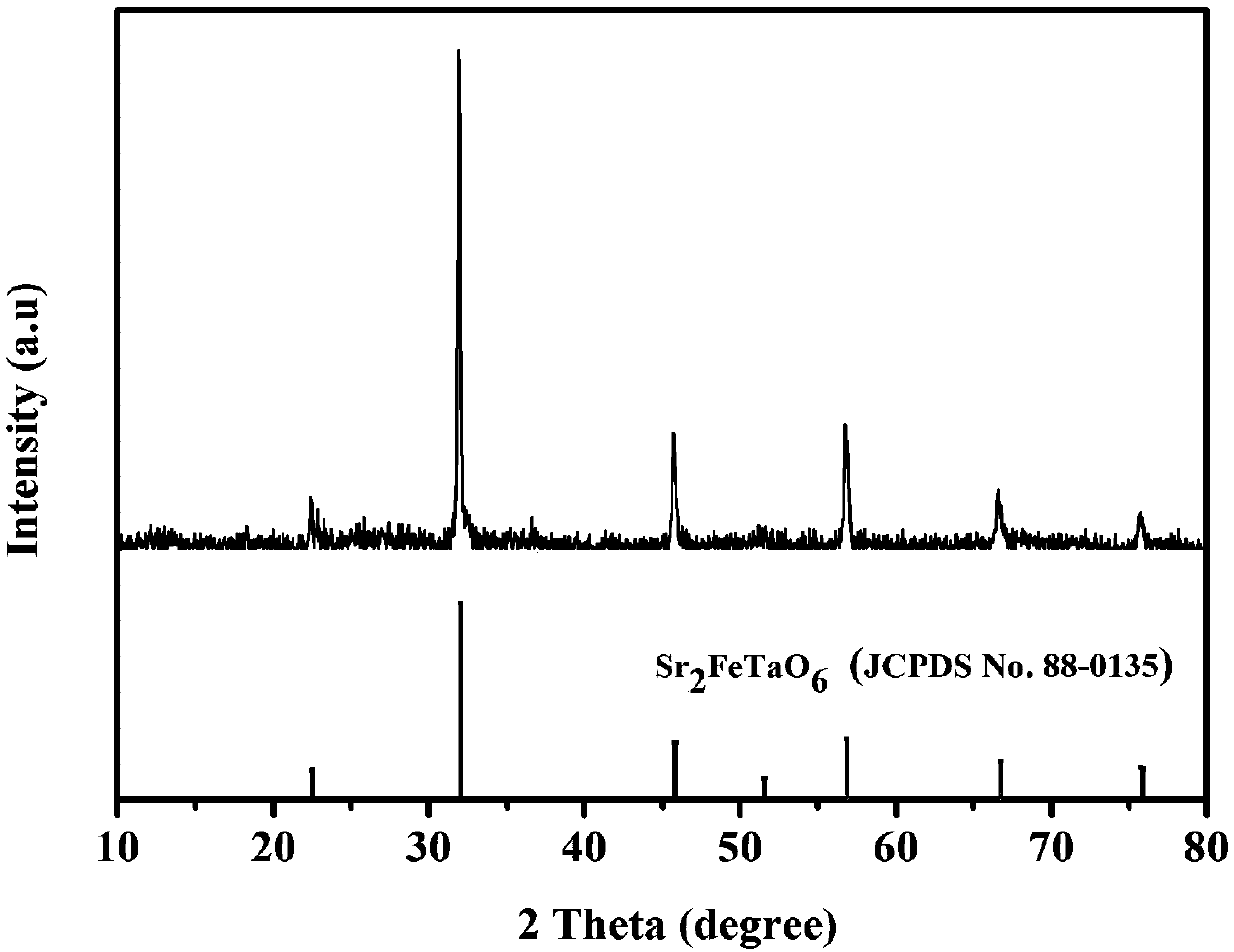

[0030] Example 1Sr 2 FeTaO 6 Preparation of / alumina composite denitration catalyst material and evaluation of catalytic denitration

[0031] (1) Dissolve 10g of strontium carbonate in excess hydrochloric acid, fully stir until the precipitation disappears completely, then add excess sodium hydroxide, after fully stirring, centrifuge the solid matter and fully wash with distilled water to obtain pure strontium hydroxide, bake Dry;

[0032] (2) 4.95g strontium hydroxide prepared by weighing 3.62g tantalum pentoxide and step (1) joins 41ml concentration and is after fully stirring in the sodium hydroxide solution of 4mol / L, adds the nanometer iron powder of 0.92g ( 300 mesh), transferred to the autoclave;

[0033] (3) Transfer the high-pressure reaction kettle in step (2) to a muffle furnace for hydrothermal reaction, raise the temperature to 400°C at a rate of 2°C / min, keep it warm for 48 hours, and cool it naturally; wash it fully with distilled water and then dry it. Get ...

Embodiment 2

[0040] The preparation method of embodiment 2 is the same as that of embodiment 1, except that hydrochloric acid is replaced by nitric acid.

[0041] The activity test method is the same as in Example 1; the conversion rate of NO is above 83%.

Embodiment 3

[0043] The preparation method of embodiment 3 is the same as that of embodiment 1, except that hydrochloric acid is replaced by sulfuric acid.

[0044] The activity testing method is the same as in Example 1; the conversion rate of NO is above 84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com