A kind of preparation method of lithium ion battery and supercapacitor electrode material

A technology for lithium-ion batteries and supercapacitors, which is applied in the manufacture of hybrid capacitor electrodes, battery electrodes, and hybrid/electric double-layer capacitors. Reaction sites cannot be fully utilized, reaction conditions are harsh, etc., to achieve the effect of improving cycle stability, excellent cycle performance, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

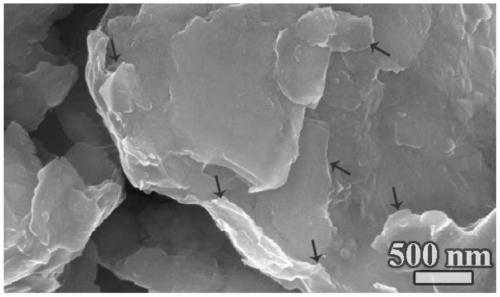

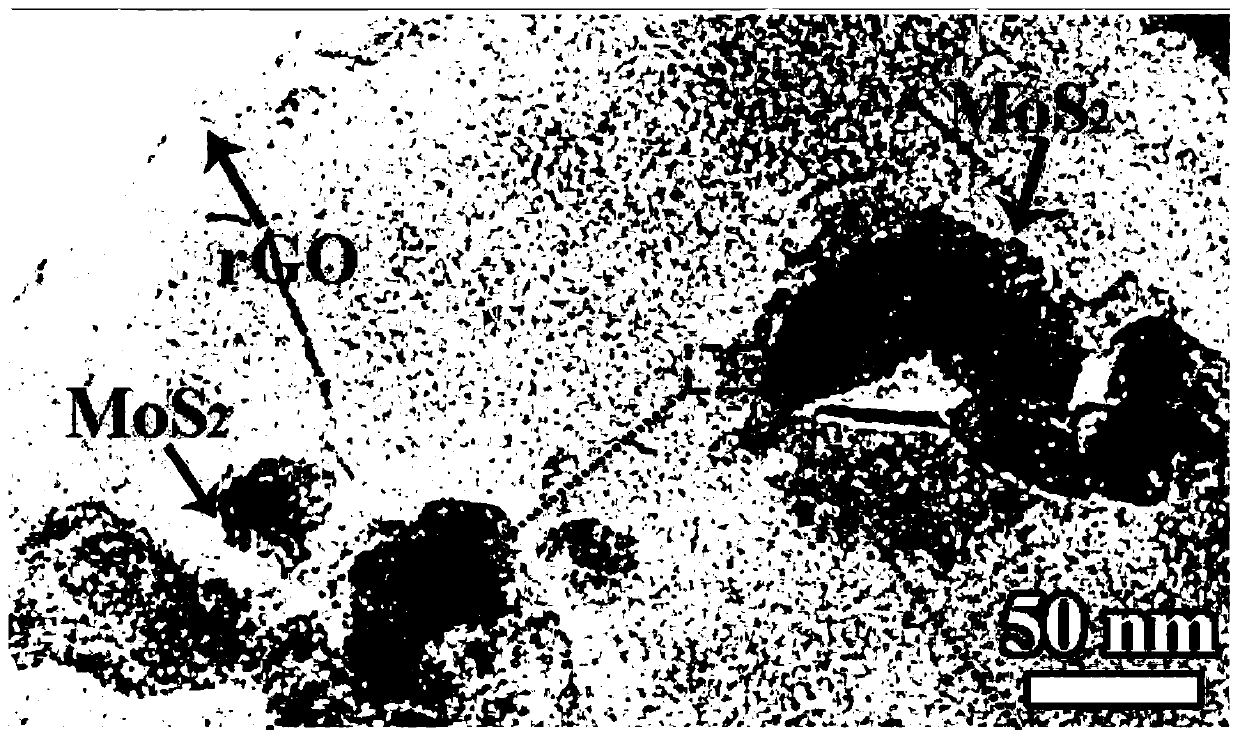

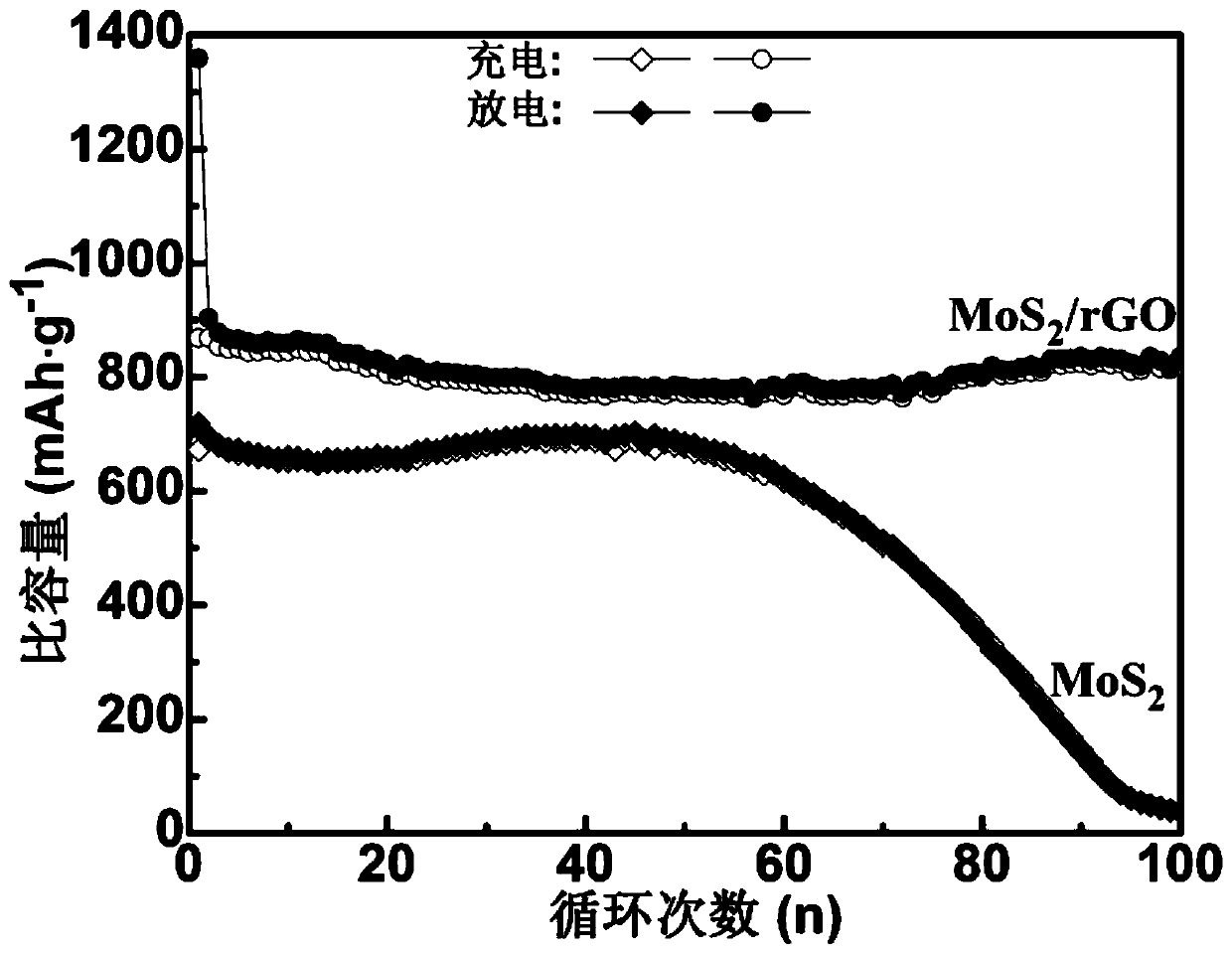

[0030] Weigh 2gMoS respectively 2 Add 2g of graphene oxide powder into the ball mill jar together; weigh another 28 g of agate balls into the ball mill jar; package the ball mill jar and perform ball milling on a planetary ball mill; set the speed of the ball mill to 500r min -1 , the agate balls were separated after ball milling for 5h to obtain few-layer MoS 2 Composite assembled with graphene. figure 1 is the scanning electron microscope image of the obtained composite. It can be seen that there are many warped parts on the edge of the layer, indicating that the ball milling process has produced effective peeling. figure 2 The transmission electron microscope image further shows the composition of the layered material after ball milling, and it can be seen that MoS with few layers and smaller size 2 The sheets are efficiently assembled with the graphene.

[0031] The resulting MoS2 / Graphene composite is used as the electrode material, mixed with the conductive agent ac...

Embodiment 2

[0034] Weigh 2gMoS respectively 2 Add 1g of graphene oxide powder into the ball mill jar; weigh 90 g of agate balls and add them to the ball mill jar; package the ball mill jar and perform ball milling on a planetary ball mill; set the ball mill speed to 400r min -1 , after ball milling for 5h, the agate balls were separated to obtain MoS 2 / graphene composite.

[0035] As a lithium-ion battery electrode material test shows: at 0.1A g –1 Under the high current density, the specific capacity of the battery reaches 850mAh·g -1 . As a supercapacitor electrode material test shows: at 4A g –1 Under the current density, the specific capacitance reaches 220F·g -1 .

Embodiment 3

[0037] Weigh 4gMoS respectively 2 Add 1g of graphene oxide powder into the ball milling jar; weigh 100 g of agate balls and add them to the ball milling jar; package the ball milling jar and perform ball milling on a planetary ball mill; set the speed of the ball mill to 350r min -1 , after ball milling for 10h, the agate balls were separated to obtain MoS 2 / graphene composite.

[0038] As a lithium-ion battery electrode material test shows: at 0.1A g –1 Under the current density, the specific capacity of the battery reaches 880mAh·g -1 . As a supercapacitor electrode material test shows: at 4A g –1 Under the current density, the specific capacitance reaches 250F·g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com