a co 2 Method for preparing bio-oil by two-step fractional hydrothermal liquefaction of lignocellulose under atmosphere

A lignocellulose and hydrothermal liquefaction technology, which is used in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oils, and the petroleum industry, etc., can solve the problems of low biomass conversion rate, high equipment performance requirements, complex product components, etc. The effect of short reaction time, high bio-oil yield and high product conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

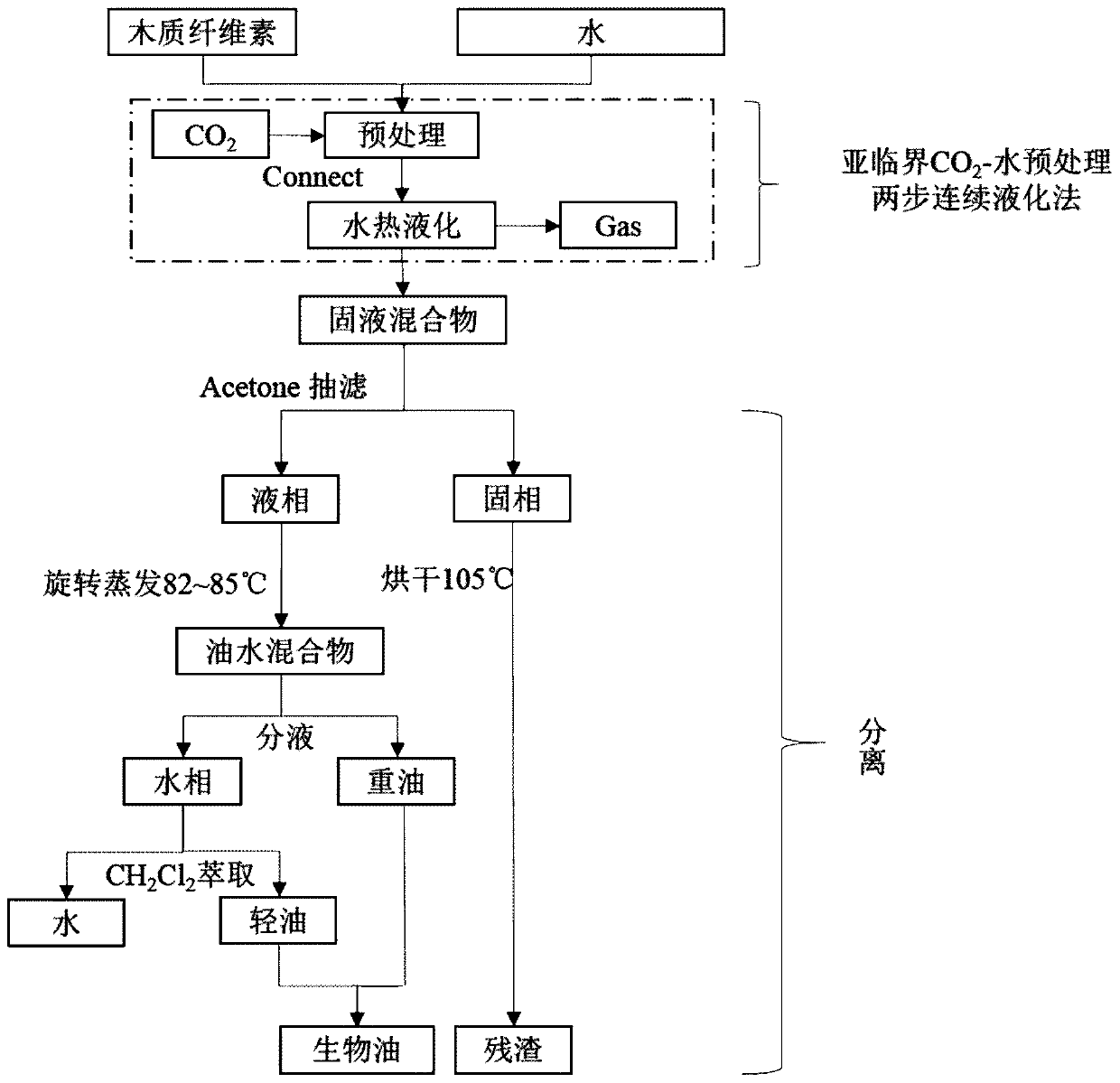

[0060] After crushing and sieving, the rice straw is selected to be 30-50 mesh. Add 15g of rice straw powder into an intermittent high-temperature and high-pressure reactor with a magnetic stirrer (Yantai Songling Chemical Industry Co., Ltd.), add 150mL of deionized water, stir evenly with a glass rod, seal the reactor, and use high-purity carbon dioxide to Purge and replace the air in the kettle. Heat to the required reaction temperature of 200°C through the heating rate of the external heating mantle, and keep for a certain reaction time of 10 minutes. The magnetic stirrer rotates at 100r / min. The above is the pretreatment step.

[0061] Then stay at 270°C, 295°C, 320°C, and 345°C for 15 minutes and 30 minutes in the high temperature stage respectively. A subsequent liquefaction stage produces bio-oil. After the reaction was over, the heating mantle was removed and the reactor was cooled by a fan. When the temperature in the kettle drops to about room temperature, open th...

Embodiment 2

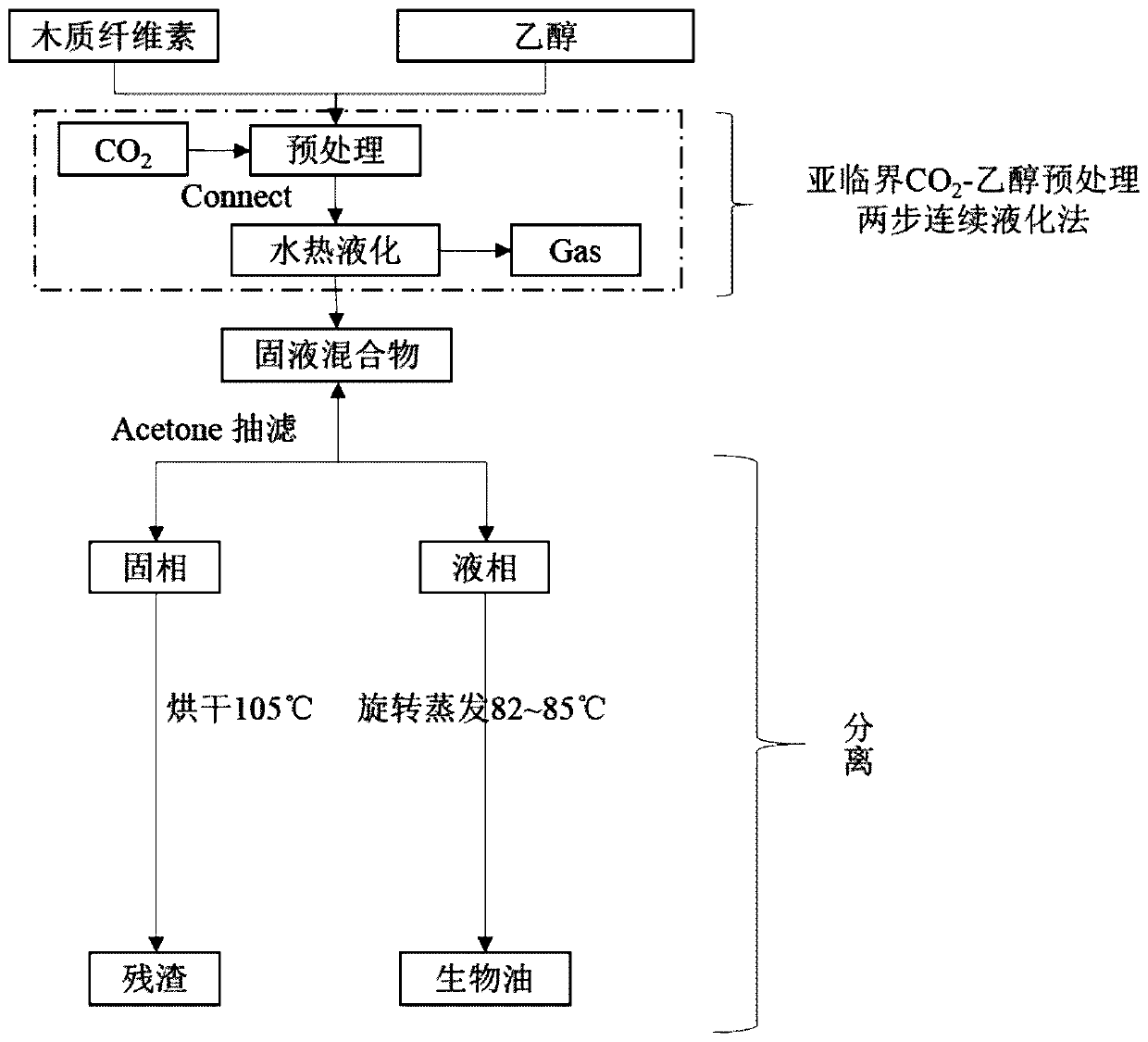

[0069] The solvent water is replaced with ethanol, and the specific operation is the same as that of Example 1. In the separation step, the mixture is suction-filtered with acetone, and the bio-oil can be obtained after constant-temperature rotary evaporation in a water bath at 82-85°C. As shown in Table 6, the product conversion rate can reach about 41.83-80.16%, and the bio-oil yield is 26.40-47.78%. As shown in Table 7, when the reaction temperature is 320°C and the residence time is 15 minutes, the bio-oil yield is the highest at 47.78%, and the bio-oil GC-MS detects 69 compounds, most of which are ester compounds, with a calorific value of 28.62 MJ / kg.

[0070] Table 6 Distribution of liquefaction products in two-step liquefaction with ethanol as solvent

[0071]

[0072] Table 7 GC-MS analysis of two-step liquefied bio-oil with ethanol as solvent (reaction condition: 320℃, 15min)

[0073]

[0074]

[0075]

Embodiment 3

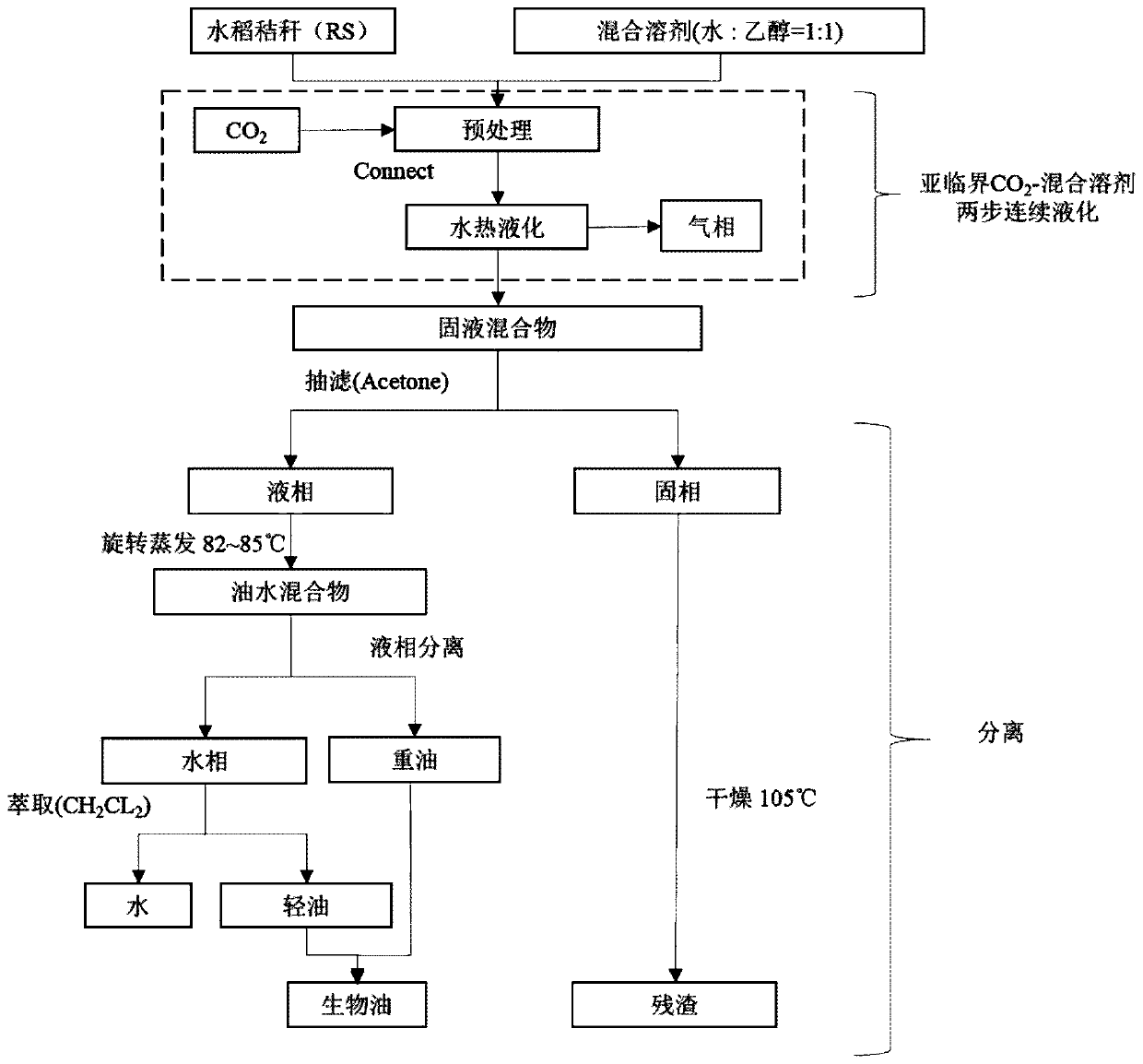

[0077] The specific operation of replacing water with a mixed solution of water and ethanol with a volume ratio of 1:1 is consistent with Example 1. As shown in Table 8, the product conversion rate can reach about 78.55-88.37%, and the bio-oil yield is 30.97-50.66%. As shown in Table 9, when the reaction temperature is 270°C and the residence time is 30 minutes, the bio-oil yield is the highest at 50.66%, and the bio-oil GC-MS detects 83 compounds with a calorific value of 24.6MJ / kg. However, when the reaction temperature is 320°C and the residence time is 30min, the highest bio-oil yield is 31.96%, and the calorific value is 30.22MJ / kg.

[0078] Table 8 Distribution of liquefaction products in two-step liquefaction with water and ethanol (volume 1:1) as solvent

[0079]

[0080]

[0081] Table 9 GC-MS analysis of two-step liquefied bio-oil with water and ethanol (volume 1:1) as solvent (reaction condition: 270℃, 30min)

[0082]

[0083]

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com