Preparation method of water-absorbing and breathable fabric

A breathable and fabric technology, applied in the field of clothing fabrics, can solve the problems of insufficient fabric softness and insufficient wearing comfort, and achieve the effects of soft hand feel, excellent water absorption and breathability, and increased thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

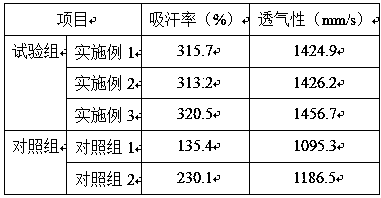

Examples

Embodiment 1

[0013] A method for making a water-absorbent and air-permeable fabric includes pretreatment of cotton yarn, preparation of modified cotton yarn, and preparation of water-absorbent and air-permeable fabric. The specific steps of the preparation method are:

[0014] 1) Cotton yarn pretreatment: Put the cotton yarn into a detergent solution with a bath ratio of 1:48 and a concentration of 1.1g / L, treat it at 92°C for 36 minutes, then wash it with water, dry it and set aside for later use. The cleaning agent is a mixture of sodium dodecylbenzenesulfonate, Remibang A and antibacterial protein with a weight ratio of 1:0.33:0.022. The amino acid sequence of the antibacterial protein is TDHKLCVYLCRVLHPGKLCVCVNCSKQDNAYASAICHGGKTCEGICADATATMDRYSDTGGPLSTARCVNAFHFYKGCSLYEENVSYKPFVVSWKYGVAGFYTHCGPNFCCCIS. surface, changing the osmotic pressure of the bacteria, and then the active substances inside the bacteria are released, which eventually leads to the death of the bacteria and kills the b...

Embodiment 2

[0018] The manufacturing method of the water-absorbing air-permeable fabric, its specific steps are:

[0019] 1) Cotton yarn pretreatment: Put the cotton yarn into a detergent solution with a bath ratio of 1:53 and a concentration of 0.9g / L, and treat it at 100°C for 20 minutes, then wash it with water, dry it and set it aside for later use. The cleaning agent is a mixture of sodium dodecylbenzenesulfonate, remibang A and antibacterial protein in a weight ratio of 1:0.36:0.02, and the amino acid sequence of the antibacterial protein is TDHKLCVYLCRVLHPGKLCVCVNCSKQDNAYASAICHGGKTCEGICADATATMDRYSDTGGPLSTARCVNAFHFYKGCSLYEENVSYKPFVVSWKYGVAGFYTHCGPNFCCCIS;

[0020] 2) Preparation of modified cotton yarn: put the pretreated cotton yarn into a low-temperature plasma processor, conduct plasma treatment at a power of 160w for 80s, and then immerse the cotton yarn in a post-treatment with a bath ratio of 1:70 In the post-treatment agent, the post-treatment agent is methyltriethoxysilane a...

Embodiment 3

[0023] The production method of the water-absorbent breathable fabric is as follows:

[0024] Put the cotton yarn into a detergent solution with a bath ratio of 1:50 and a concentration of 1g / L, treat it at 96°C for 30 minutes, then wash it with water, dry it and set it aside. : 0.35:0.021 of sodium dodecylbenzenesulfonate, remibang A and antibacterial protein mixture, the amino acid sequence of antibacterial protein is TDHKLCVYLCRVLHPGKLCVCVNCSKQDNAYASAICHGGKTCEGICADATATMDRYSDTGGPLSTARCVNAFHFYKGCSLYEENVSYKPFVVSWKYGVAGFYTHCGPNFCCCIS;

[0025] Put the pretreated cotton yarn into a low-temperature plasma processor, perform plasma treatment for 90s at a power of 150w, then immerse the cotton yarn in a post-treatment agent with a bath ratio of 1:60, and the post-treatment agent is by weight Methyltriethoxysilane and dimethyldiethoxysilane with a ratio of 1:0.023 were post-treated at 100°C for 30 minutes, then the yarn was taken out, washed with absolute ethanol and distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com