A kind of preparation method of nanometer ruthenium oxide

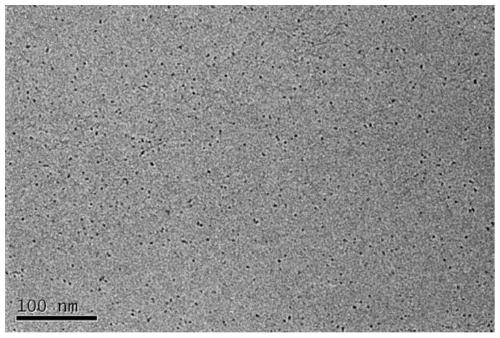

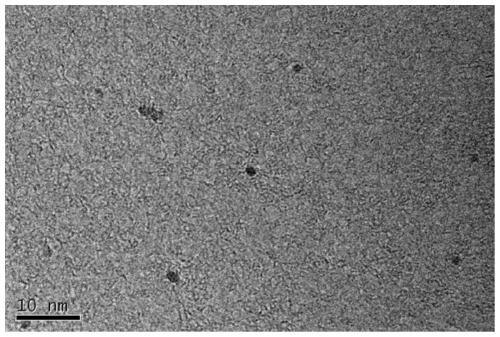

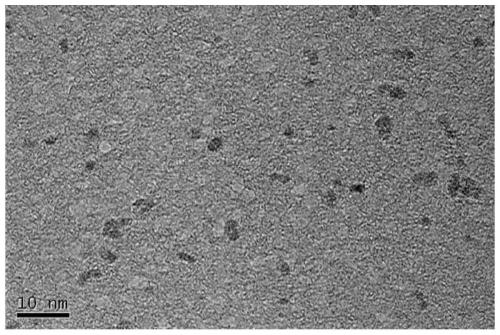

A ruthenium oxide and nanotechnology, applied in the field of nanomaterials, can solve the problems of unfavorable application, serious agglomeration of ruthenium oxide, poor particle crystallinity, etc., and achieve the effects of strong experimental repeatability, uniform particle size, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method for nanometer ruthenium oxide, comprising the steps of:

[0043] 1) Dissolve 1 g of ruthenium trichloride hydrate in 100 mL of deionized water, and sonicate for 0.2 h;

[0044] 2) Dissolve 0.56g of sodium hydroxide in 100mL of deionized water, and sonicate for 0.2h;

[0045] 3) Pass the ruthenium trichloride source solution and sodium hydroxide solution into the high-gravity rotating bed through a peristaltic pump at a feed flow rate of 600mL / min, and the rotating bed speed is 1200r / min to obtain a precursor solution. The pH of the precursor solution is 9 ;

[0046] 4) Place the obtained precursor solution in an oven, adjust the temperature to 80°C, and age for 3 hours;

[0047] 5) Take out the precursor solution, centrifuge and wash 6 times at 7500r / min;

[0048] 6) Transfer the washed precipitate to a polytetrafluoroethylene reactor, add 100mL of deionized water, and heat at 160°C for 12 hours;

[0049] 7) drying the taken out precipitate in a...

Embodiment 2

[0052] A preparation method for nanometer ruthenium oxide, comprising the steps of:

[0053] 1) Dissolve 6 g of hexaammonium ruthenium trichloride in 500 mL of absolute ethanol, and sonicate for 0.5 h;

[0054] 2) Prepare 5mol / L ammonia solution, take out 1.5mL ammonia water and add 98.5mL ethanol;

[0055] 3) Hexaammonium trichloride ruthenium solution and ammonia water are respectively fed into the high gravity rotary bed through a peristaltic pump at a feed flow rate of 500mL / min, and the rotary bed speed is 2500r / min to obtain a precursor solution, and the pH of the precursor solution is 10;

[0056] 4) Place the obtained precursor solution in an oven, adjust the temperature to 80°C, and age for 3 hours;

[0057] 5) Take out the precursor solution, centrifuge and wash 6 times at 7500r / min;

[0058] 6) Transfer the washed precipitate to a polytetrafluoroethylene reactor, add 100mL of deionized water, and heat at 100°C for 12 hours;

[0059] 7) drying the taken out precip...

Embodiment 3

[0062] A preparation method for nanometer ruthenium oxide, comprising the steps of:

[0063] 1) Dissolve 3 g of ruthenium nitrosyl nitrate in 300 mL of deionized water / ethanol at a ratio of 1:1, and sonicate for 0.5 h;

[0064] 2) Dissolve 1.68g of sodium hydroxide in 300mL of deionized water / ethanol at a ratio of 1:1, and sonicate for 0.5h;

[0065] 3) Feed the ruthenium nitrosyl nitrate source solution and the sodium hydroxide solution into the high-gravity rotating bed through a peristaltic pump with a feed flow rate of 400mL / min, and the rotating bed speed is 1200r / min to obtain a precursor solution. The pH of the precursor solution is 9;

[0066] 4) Place the obtained precursor solution in an oven, adjust the temperature to 70°C, and age for 3 hours;

[0067] 5) Take out the precursor solution, centrifuge and wash 6 times at 7500r / min;

[0068] 6) Transfer the washed precipitate to a polytetrafluoroethylene reactor, add 100mL of deionized water, and conduct a hydrother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com