Preparation method and application of polymer hollow microcapsule

A polymer and hollow micro technology, applied in botany equipment and methods, microcapsules, applications, etc., to achieve the effect of simple reaction conditions, easy mass production, and adjustable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The specific embodiment that prepares oil-in-water Pickering emulsion with hydrophilic nanocellulose as emulsifying agent is as follows:

[0045] 1) dispersing hydrophilic nanocellulose in an aqueous solution containing sodium chloride as the aqueous phase A of the Pickering emulsion;

[0046] 2) using oily solvent toluene as the oil phase B of the Pickering emulsion;

[0047] 3) Mix the above-mentioned water phase A and oil phase B according to the ratio of 7:3, and use an ultrasonic cell pulverizer to sonicate for 2 minutes to obtain an oil-in-water Pickering emulsion.

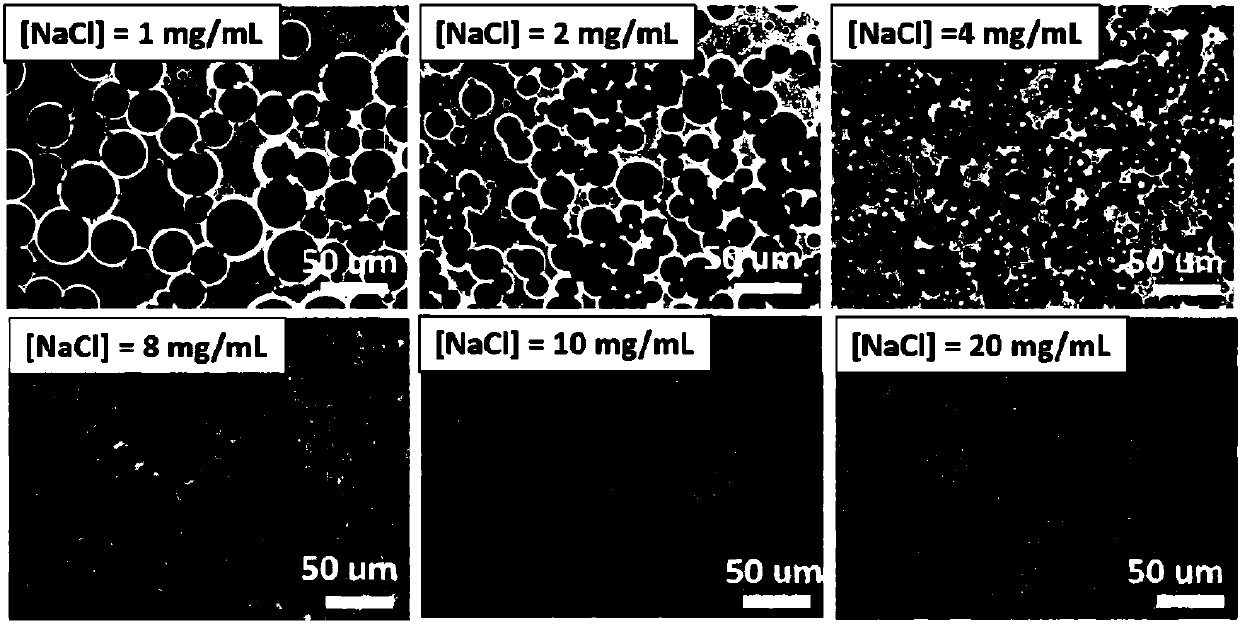

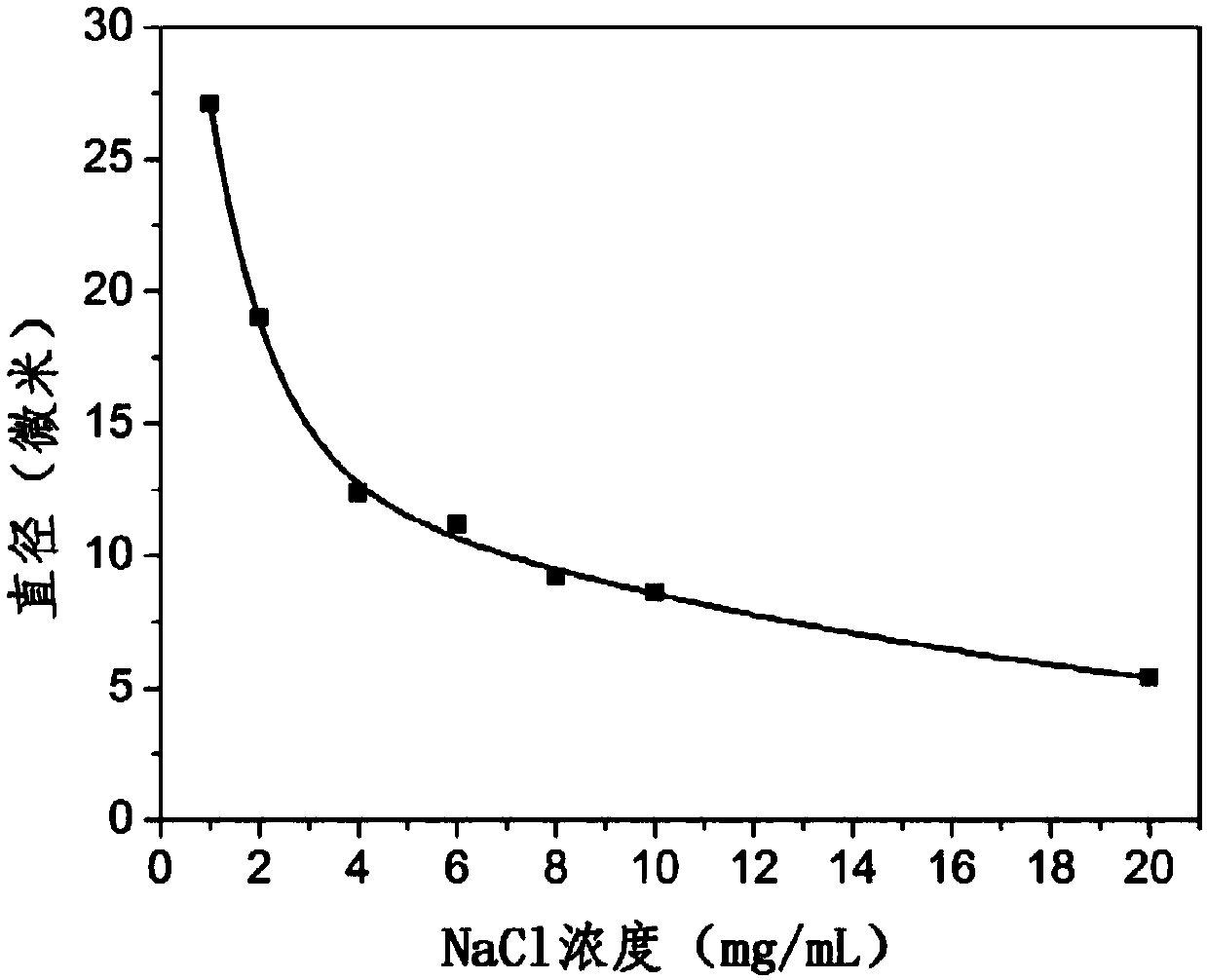

[0048] The test parameters and test results are summarized as follows:

[0049]

[0050]

[0051] According to experiments 1 to 8, the diameter of the Pickering emulsion droplet is closely related to the concentration of sodium chloride in the aqueous phase. The surface of nanocellulose prepared by sulfuric acid hydrolysis has a strong negative charge, and a certain amount of salt needs to be ...

Embodiment 2

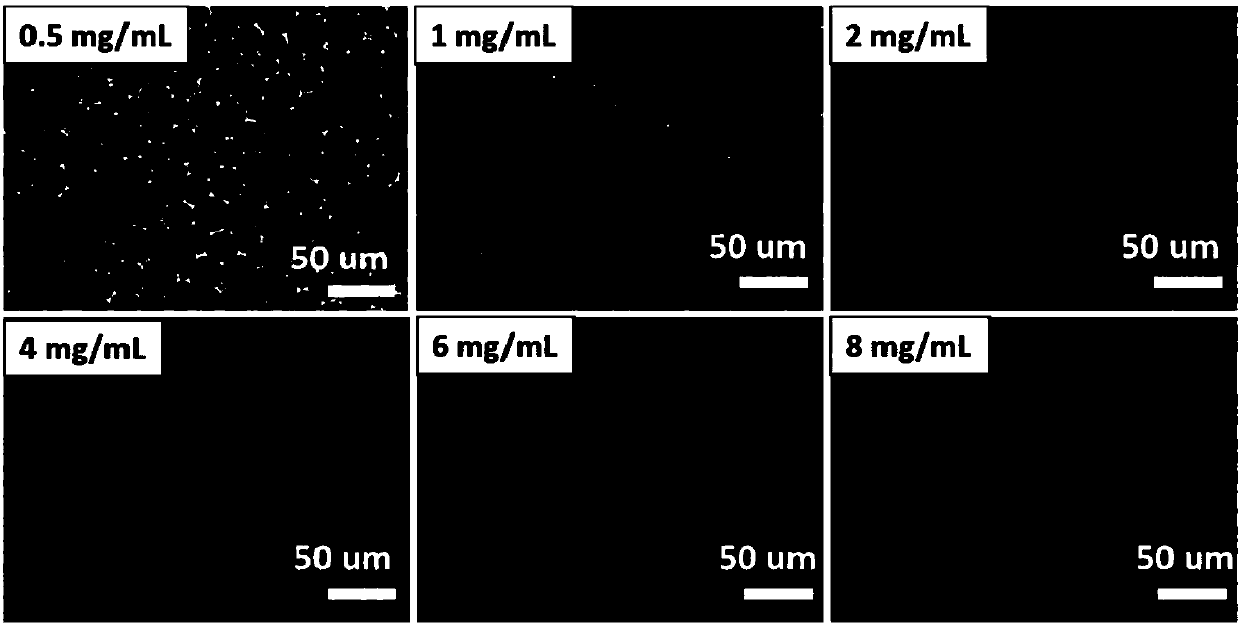

[0054] Using the oil-in-water Pickering emulsion of hydrophilic nanocellulose emulsification as a template, the specific examples of preparing polymer hollow microcapsules (hollow microcapsule, HM) are as follows:

[0055] 1) dispersing hydrophilic nanocellulose in an aqueous solution containing sodium chloride as the aqueous phase A of the Pickering emulsion;

[0056] 2) Using oily solvent, oil-soluble initiator azobisisobutyronitrile (AIBN), different polymer monomers and crosslinking agent divinylbenzene as the oil phase B of the Pickering emulsion;

[0057] 3) The above-mentioned water phase A and oil phase B were mixed according to the ratio of 7:3, and the nitrogen gas was continuously introduced for 30 minutes, and then the Pickering emulsion was obtained after ultrasonic cell pulverizer was used for 2 minutes under the protection of nitrogen gas. Kling emulsion was reacted at 70 degrees Celsius for 12 hours;

[0058] 4) Finally, the above reaction solution was washed ...

Embodiment 3

[0068] The concrete embodiment that prepares water-in-oil Pickering emulsion with hydrophobic nanocellulose as emulsifying agent is as follows:

[0069]1) Firstly, hydrophobic modification is carried out to the hydrophilic nanocellulose to prepare hydrophobic nanocellulose. Hydrophobic nanocellulose can be obtained by introducing hydrophobic groups on nanocellulose through small molecule reaction or polymer grafting. In this example, butyryl chloride or cinnamic acid chloride was used to hydrophobically modify nanocellulose. Disperse 1 gram of nanocellulose into 100 milliliters of dimethylformamide, add 1 milliliter of triethylamine, 1 gram of 4-dimethylaminopyridine and 1 gram of butyryl chloride or cinnamoyl chloride, and react at room temperature for 24 hours to obtain Hydrophobically modified nanocellulose;

[0070] 2) dispersing the above-mentioned hydrophobic nanocellulose in an oily solvent as the oil phase A of the Pickering emulsion;

[0071] 3) Use water as the aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com