Aflatoxin-adsorbing filter cloth, preparation method and application thereof

A technology of aflatoxin and filter cloth, which is applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of cumbersome operation, high oil viscosity, low reuse rate, etc., achieve good permeability and increase contact area and chance, combined with stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

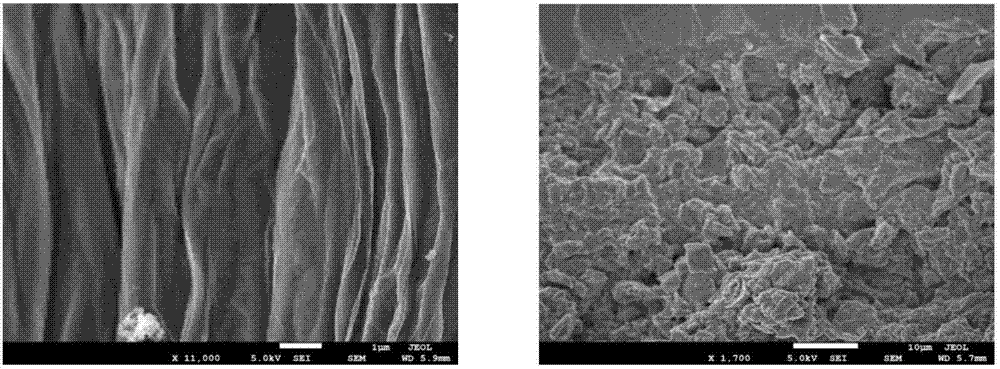

[0032] (1) Preparation of filter cloth for absorbing aflatoxin

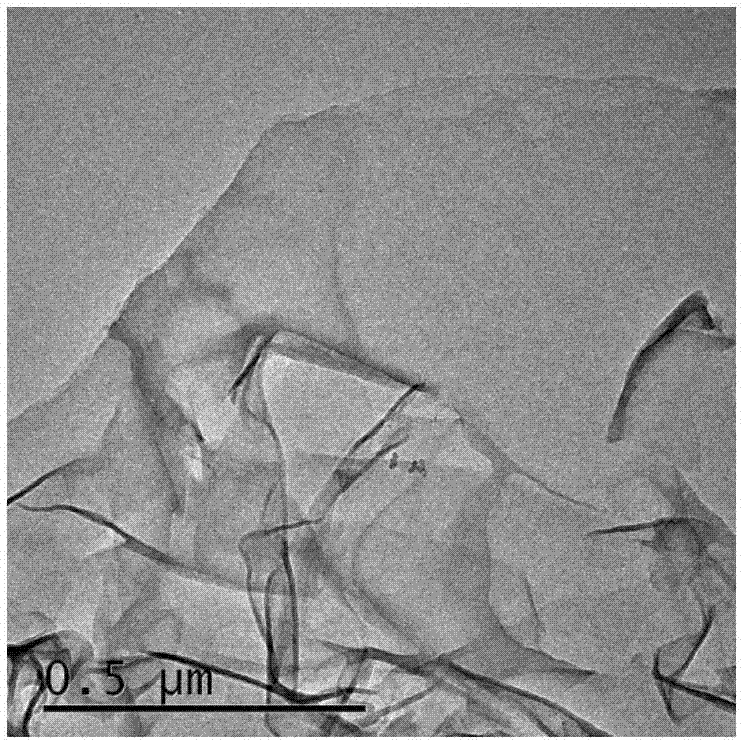

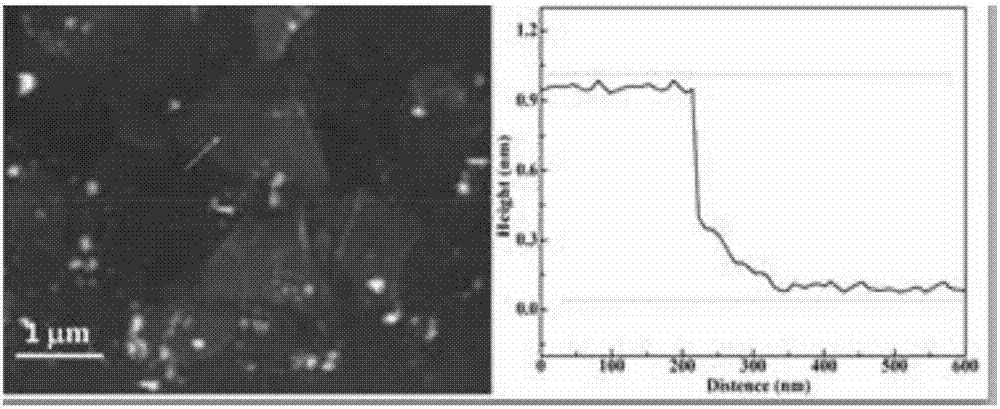

[0033] Pass 3.0g of flake graphite through a 325 mesh sieve and add it to 400mL of a mixed solution of sulfuric acid and phosphoric acid at a volume ratio of 9:1, and stir for 10 minutes; then slowly add 18.0g of potassium permanganate to the mixture (do not add too much each time , to avoid the reaction temperature exceeding 20°C). After the potassium permanganate was added, the mixture was heated to 50°C and stirred for 12 hours. After the reaction, let the mixture cool down to room temperature naturally, pour it into ~400mL of ice water, keep stirring at room temperature for 0.5h, and finally add 30wt% hydrogen peroxide dropwise to the reaction system until the solution turns bright yellow. Let it stand overnight, pour off the supernatant, wash 3 times with 1L hydrochloric acid with a mass fraction of 5% to 10%, and then wash 5 times with 1L deionized water to remove metal ions, sulfate ions and chloride ions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com