Method for preparing nitrogen-doped carbon aerogel

A technology of carbon airgel and nitrogen doping, which is applied in the direction of nano-carbon, electrical components, electrochemical generators, etc., can solve the problems of long cycle, complicated preparation process, single structure of carbon airgel, etc., and achieve low price , rich nitrogen content, and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing nitrogen-doped carbon airgel, comprising the following steps:

[0025] Step 1: Add 2 g of bean dregs to 30 mL of concentrated sulfuric acid with a mass concentration of 30% and stir at 600 r / min for 5 h to form a carbon sol precursor.

[0026] Step 2: The carbon sol precursor was diluted 5 times with water, that is, the amount of water added was 4 times the volume of concentrated sulfuric acid, and then microwave hydrothermal treatment was performed at a temperature of 150°C for 90 minutes to obtain a carbon aerogel.

[0027] Step 3: Suction filter the obtained carbon aerogel, dry it in an oven at 60°C and put it into a nitrogen atmosphere furnace, raise the temperature from room temperature to 600°C at a rate of 5°C / min, and the flow rate of nitrogen gas 60mL / min, keep warm for 90min. Nitrogen-doped carbon aerogels can be obtained after cooling.

Embodiment 2

[0029] A method for preparing nitrogen-doped carbon airgel, comprising the following steps:

[0030] Step 1: Add 2 g of bean dregs to 32 mL of concentrated sulfuric acid with a mass concentration of 50% and stir at 500 r / min for 6 h to form a carbon sol precursor.

[0031] Step 2: Dilute the carbon sol precursor 6 times with water, that is, the amount of water added is 5 times the volume of concentrated sulfuric acid, and then perform microwave hydrothermal treatment at a temperature of 160°C for 100 minutes to obtain carbon airgel.

[0032] Step 3: Suction filter the obtained carbon aerogel, dry it in an oven at 70°C and put it in a nitrogen atmosphere furnace, raise the temperature from room temperature to 700°C at a rate of 6°C / min, and the flow rate of nitrogen gas 60mL / min, heat preservation for 100min, and nitrogen-doped carbon airgel can be obtained after cooling.

Embodiment 3

[0034] A method for preparing nitrogen-doped carbon airgel, comprising the following steps:

[0035] Step 1: Add 2 g of bean dregs to 34 mL of concentrated sulfuric acid with a mass concentration of 40% and stir at 400 r / min for 7 h to form a carbon sol precursor.

[0036] Step 2: The carbon sol precursor was diluted 7 times with water, that is, the amount of water added was 6 times the volume of concentrated sulfuric acid, and then microwave hydrothermal treatment was performed at a temperature of 160°C for 100 minutes to obtain a carbon aerogel.

[0037] Step 3: Suction filter the obtained carbon aerogel, dry it in an oven at 70°C, put it into a nitrogen atmosphere furnace, and raise the temperature from room temperature to 800°C at a rate of 7°C / min. 70mL / min, keep warm for 120min. Nitrogen-doped carbon aerogels can be obtained after cooling.

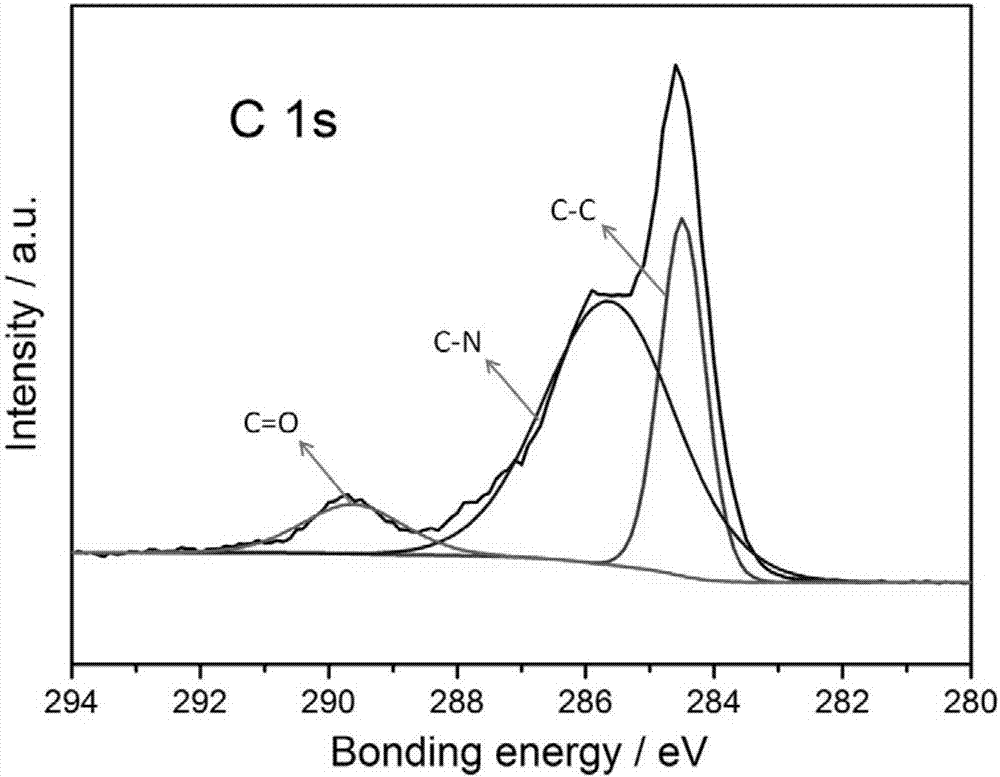

[0038] Depend on figure 1 It can be seen that the carbon airgel prepared by the present invention contains C-N bonds.

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com