Method for preparing tert-amyl alcohol

A technology of tert-amyl alcohol and isopentene, which is applied in the field of preparation of tert-amyl alcohol, can solve the problems of long reaction time and high energy consumption, and achieve the effects of accelerated reaction rate, improved mass transfer rate and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

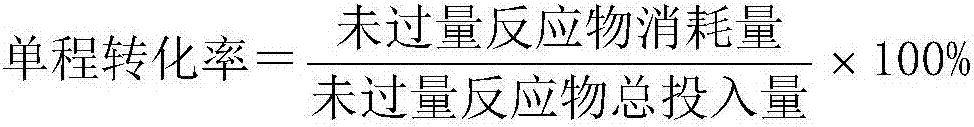

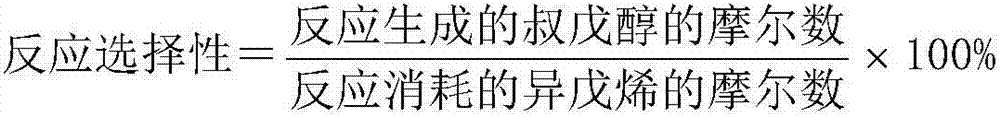

[0028] The crude isoamylene component (98% isoamylene content) produced by the isoamylene plant of Shanghai Petrochemical Co., Ltd., deionized water and co-catalyst tetrabutylammonium bromide were used at a water-to-ene molar ratio of 1:10, After being metered by a metering pump, they are mixed by a high-efficiency static mixer, and the preheater is preheated to 60°C, and then enters a fixed-bed reactor. The co-catalyst is used in an amount of 0.02% by weight of isopentene. After the material is distributed by the distributor, it passes through the bed layer mixed with inert magnetic balls and resin catalyst for hydration reaction. The reactor was filled with 20 mL of cation exchange resin (Dow Chemical Company, Amberlyst type 35). The conditions of the hydration reaction are reaction temperature 60°C, reaction pressure 1.2MPa, liquid hourly volume space velocity 0.25h -1 . The material comes out of the reactor and is cooled to room temperature through a condenser. System ...

Embodiment 2

[0031] Amberlyst 35 type cation exchange resin was adopted as the catalyst, and tetrabutylammonium bromide was used as the cocatalyst, and the loading amount of the catalyst was the same as in Example 1. The co-catalyst is used in an amount of 0.08% by weight of isopentene. The ratio of raw materials is that the molar ratio of water to ene is 1:5, the hydration reaction conditions are reaction temperature 50°C, reaction pressure 1.5MPa, liquid hourly volume space velocity 0.5h -1 . The single-pass conversion rate of the reaction is 40.8%, and the selectivity is 99.7%.

[0032] Carry out distillation according to the said method of embodiment 1, the purity that records tert-amyl alcohol by chromatographic analysis is 99.2%.

Embodiment 3

[0034] Adopt QRE-01 type cation exchange resin as catalyst, use tetrabutylammonium bromide as cocatalyst, and the loading amount of catalyst is the same as Example 1. The co-catalyst is used in an amount of 0.15% by weight of isopentene. Raw material ratio is water-ene molar ratio of 1:3, hydration reaction conditions are reaction temperature 80°C, reaction pressure 0.5MPa, liquid hourly volume space velocity 0.8h -1 . The single-pass conversion rate of the reaction is 59.6%, and the selectivity is 99.0%.

[0035] Carry out distillation according to the said method of embodiment 1, the purity that records tert-amyl alcohol by chromatographic analysis is 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com