Preparation method for high-strength activated form polyester industrial yarns

An activated and industrial yarn technology, applied in the direction of single-component polyester rayon, fiber type, melt spinning method, etc., can solve the problems of oligomer affecting fiber quality, fiber uneven spinneret, etc., and achieve effective Good for fiber quality, improved performance, and easy diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

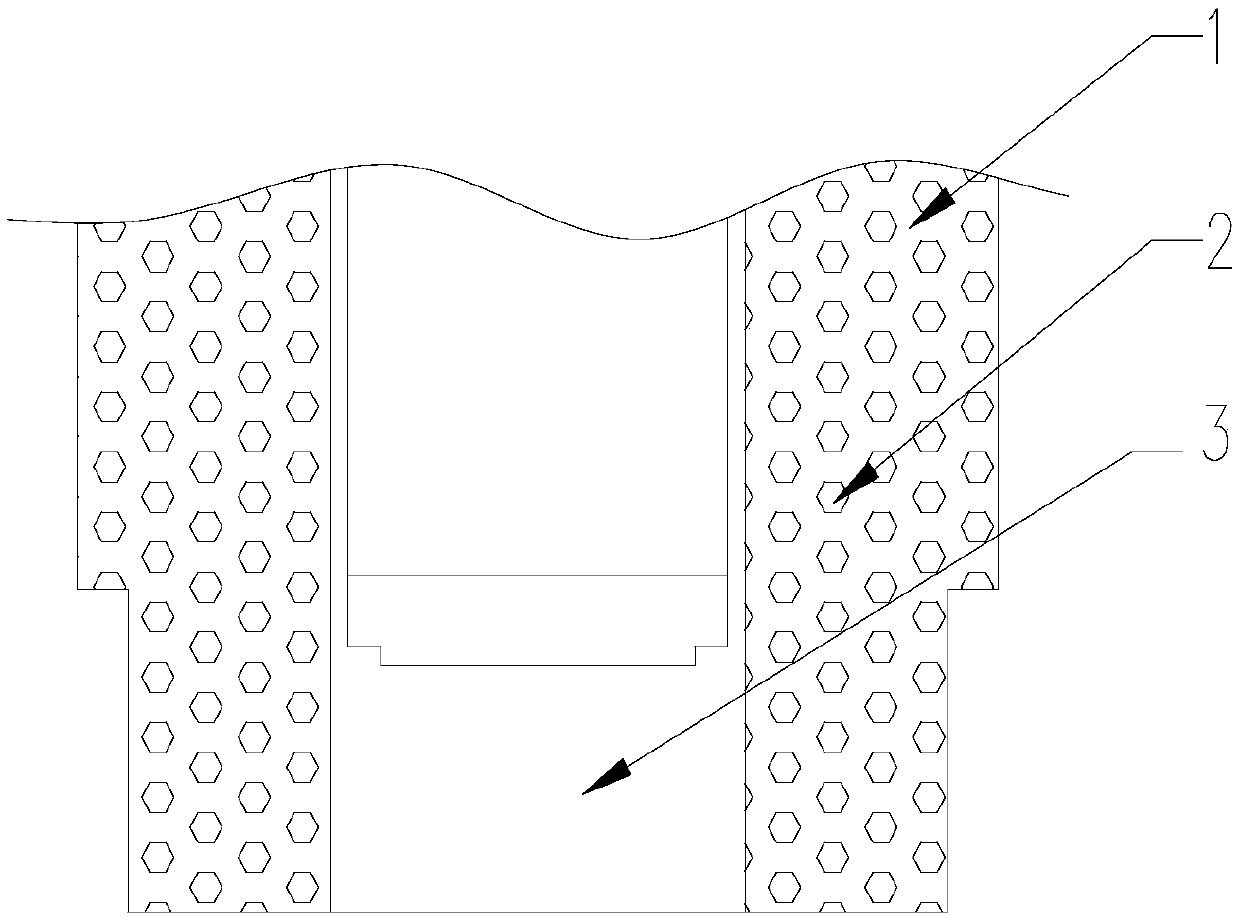

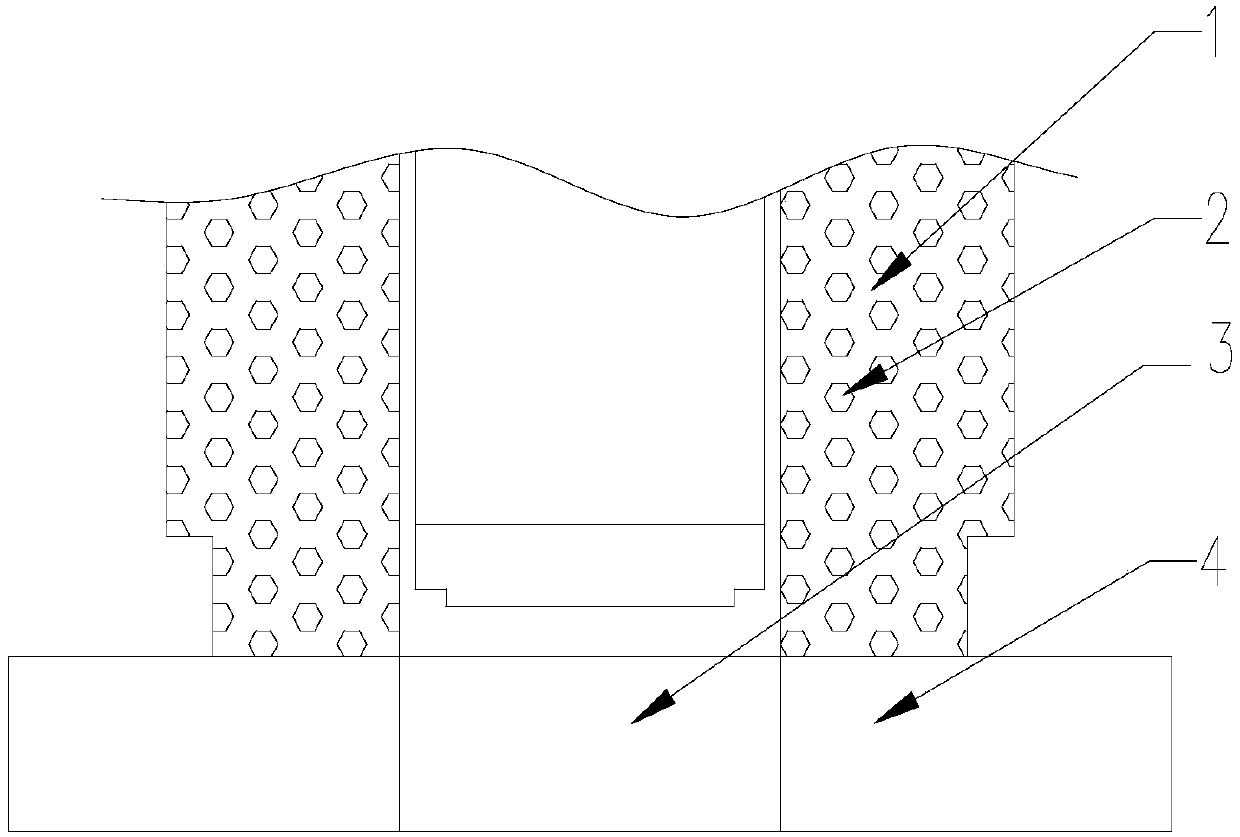

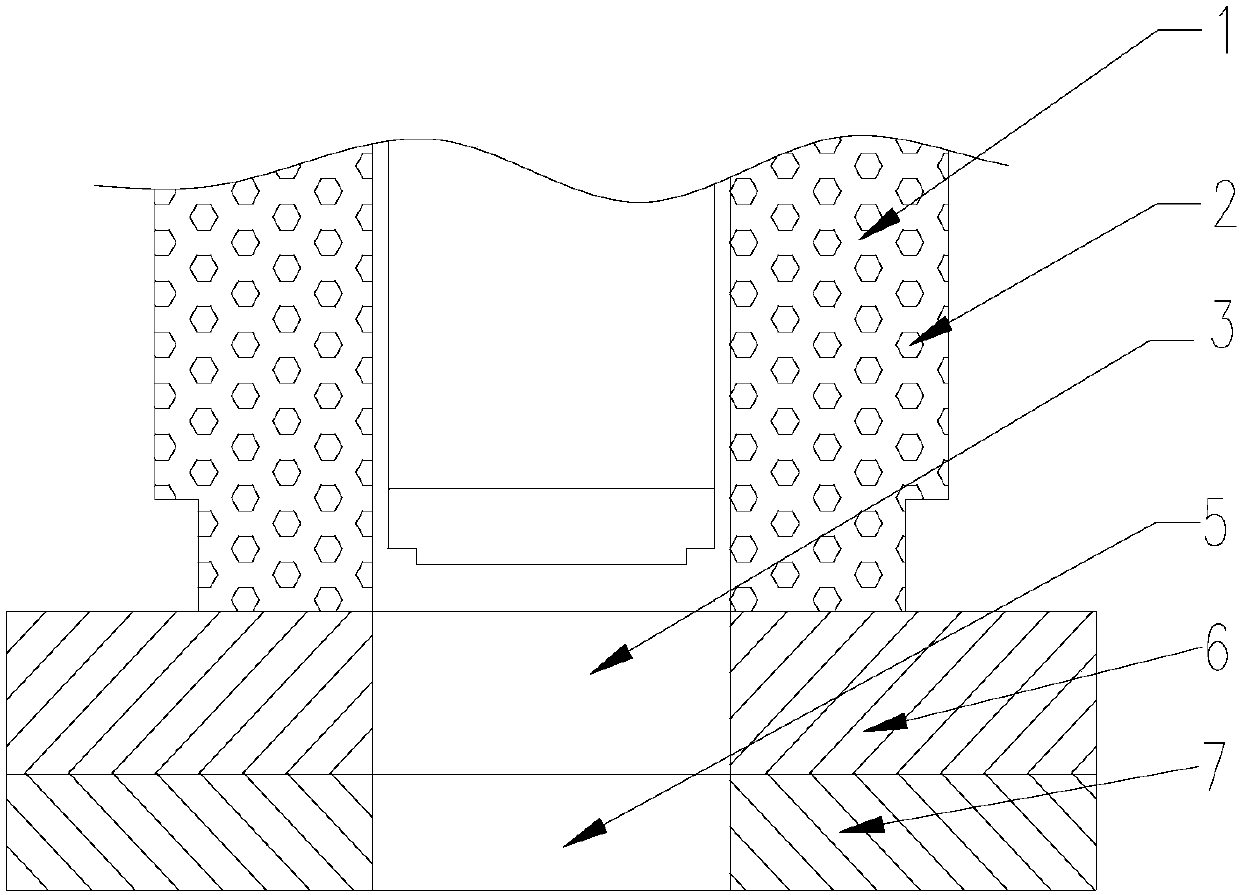

Image

Examples

Embodiment 1

[0063] A preparation method of high-strength activated polyester industrial yarn, the steps are as follows:

[0064] (1) Preparation of oiling agent for oiling;

[0065]Mix 2-hydroxymethyl-12-crown-4 with potassium dodecyl phosphate, trimethylolpropane laurate and sodium dodecylsulfonate at room temperature and add to 9# mineral oil and uniformly stirred at 40°C for 1 hour to obtain an oil agent. The addition amount of each component is as follows in parts by weight: 2 parts of 9# mineral oil; 10 parts of trimethylolpropane laurate; 2-methylolpropane laurate Base-12-crown-4 is 90 parts; Potassium dodecyl phosphate is 8 parts; Sodium dodecyl sulfonate is 3 parts; The content of crown ether in the prepared oil is 79.6wt%. The high temperature resistance of the agent is excellent, and the thermal weight loss after heat treatment at 200°C for 2 hours is 14.5wt%; the viscosity of the oil agent is low, and the kinematic viscosity is 29.6mm at (50±0.01)°C 2 / s, the kinematic viscos...

Embodiment 2

[0070] A preparation method of high-strength activated polyester industrial yarn, the steps are as follows:

[0071] (1) Preparation of oiling agent for oiling;

[0072] Mix 15-crown ether-5 with potassium tridecyl alcohol polyoxyethylene ether phosphate, trimethylolpropane laurate and sodium pentadecylsulfonate at room temperature and add to 10# mineral oil and uniformly stirred at 43°C for 1.5h to obtain an oil agent. The addition amount of each component is as follows in parts by weight: 2 parts for 10# mineral oil; 15 parts for trimethylolpropane laurate; 15 parts for 15-crown Ether-5 is 70 parts; isomeric tridecanol polyoxyethylene ether phosphate potassium salt is 10 parts; sodium pentadecylsulfonate is 7 parts; the content of crown ether in the prepared oil agent is 67.30wt%, The oil agent has excellent high temperature resistance, and the thermal weight loss is 13wt% after heat treatment at 200°C for 2 hours; the viscosity of the oil agent is low, and the kinematic vi...

Embodiment 3

[0077] A preparation method of high-strength activated polyester industrial yarn, the steps are as follows:

[0078] (1) Preparation of oiling agent for oiling;

[0079] Mix 2-hydroxymethyl-15-crown-5 with tetradecyl alcohol phosphate potassium salt, trimethylolpropane laurate and sodium pentadecylsulfonate at room temperature and add to 11# mineral in oil and uniformly stirred at 48°C for 3 hours to obtain an oil agent. The addition amount of each component is as follows in parts by weight: 8 parts for 11# mineral oil; 10 parts for trimethylolpropane laurate; 10 parts for 2-hydroxy 85 parts of methyl-15-crown-5; 11 parts of potassium tetradecyl alcohol phosphate; 5 parts of sodium pentadecylsulfonate; the content of crown ether in the prepared oil is 70.83wt% , the high temperature resistance of the oil is excellent, the thermal weight loss is 11wt% after heat treatment at 200°C for 2 hours; the viscosity of the oil is low, at (50±0.01)°C, the kinematic viscosity is 30.1mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Wicking height | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com