Preparation method of composite functional xylooligosaccharide composition for facilitating drying and resisting moisture absorption

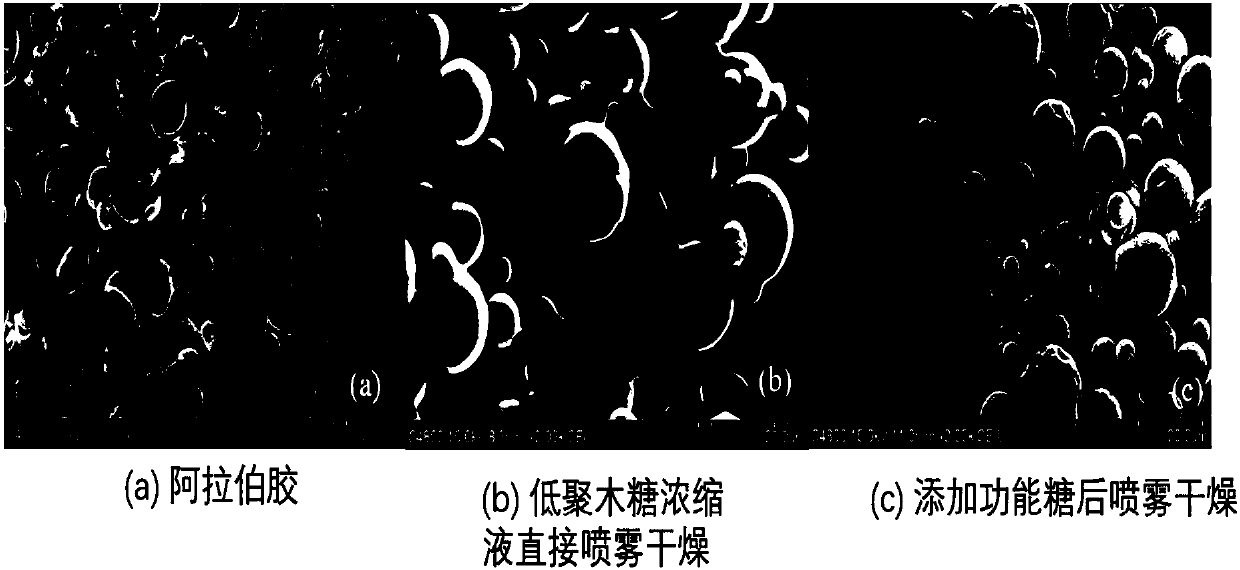

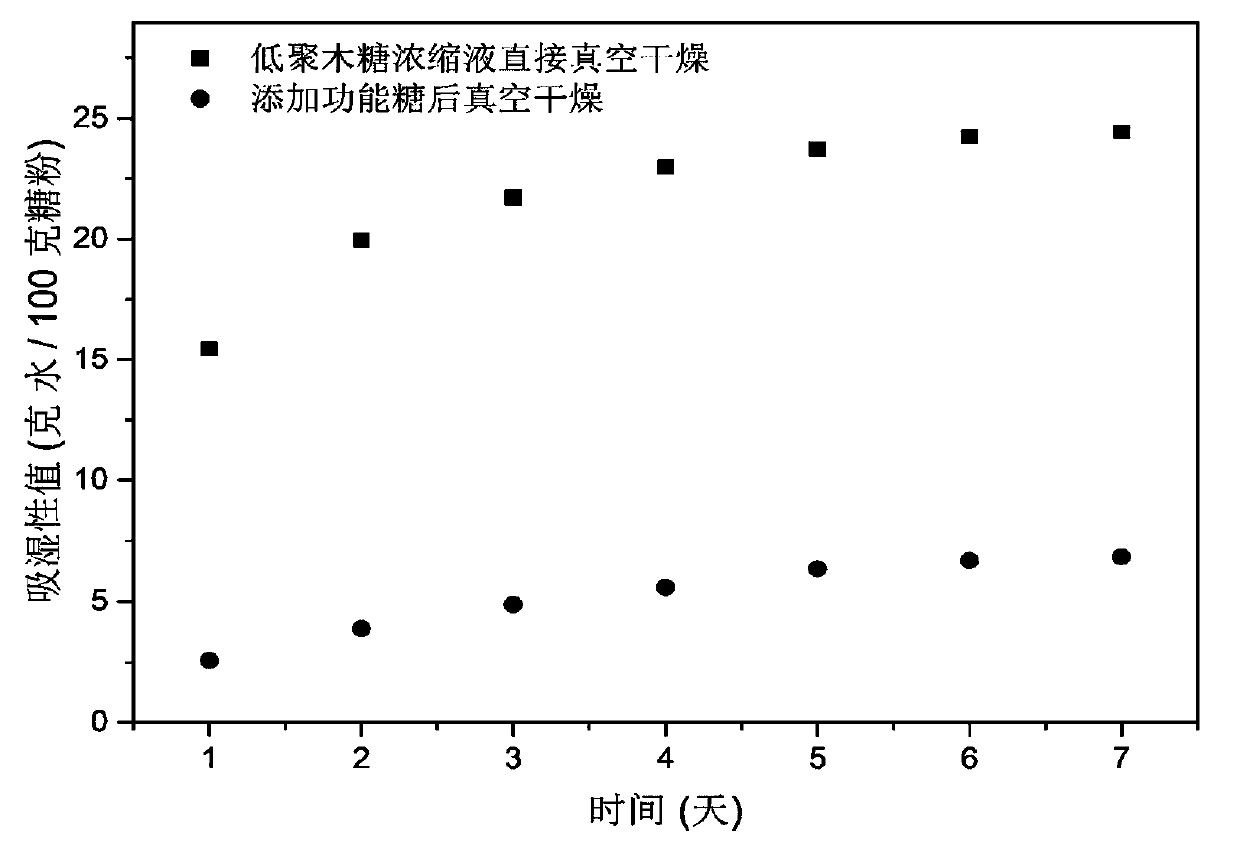

A xylo-oligosaccharide, functional technology, applied in the field of food science, can solve the problems affecting processing, storage, transportation, sales and utilization, products are prone to stick to the wall, easy to absorb moisture and become sticky, etc., to enhance human immunity. , The effect of optimizing intestinal flora and stabilizing SOD activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) After pretreatment, saccharification, plate and frame filtration, sterilization, decolorization, ion exchange, purification and concentration of xylo-oligosaccharide production raw materials, the content of 80 wt. % (80wt% in dry matter total sugar is xylooligosaccharide) xylooligosaccharide concentrate, specifically as follows:

[0035] a. Mix deionized water, xylooligosaccharide production raw materials and MgO at a weight ratio of 5:1:0.15, and cook at 165° C. for 3 hours. Squeeze out the yellow liquid in the cooked pulp and wash it 6 times with deionized water, then extract it with 10wt% KOH aqueous solution for 6h, filter and remove the cellulose to obtain the filtrate, then precipitate the filtrate with 4 times the volume of absolute ethanol to obtain the rich Xylan-containing hemicellulose;

[0036] b. Saccharification: mix deionized water, the above-mentioned xylan-rich hemicellulose and xylanase in a weight ratio of 9:1:0.05, and then saccharify in a solut...

Embodiment 2

[0044] (1) After pretreatment, saccharification, plate and frame filtration, sterilization, decolorization, ion exchange, purification and concentration of xylo-oligosaccharide production raw materials, the content obtained with a refractive index of 70% (equal to total sugar in dry matter) is 60wt % (60wt% in the total sugar of dry matter is xylooligosaccharide) concentrated solution of xylooligosaccharides, specifically with embodiment 1;

[0045] (2) Dihydrate crystalline trehalose, mannitol and gum arabic were heated and dissolved in deionized water at 70°C to obtain dihydrate crystalline trehalose solution, mannitol solution and gum arabic solution respectively. Xylan concentrated solution, dihydrate crystalline trehalose solution and mannitol solution are added to the gum arabic solution, and fully mixed; the mass ratio of the dihydrate crystalline trehalose, mannitol and acacia gum is 12:18:20, and the above The weight ratio of the dry matter total sugar in the xylo-oli...

Embodiment 3

[0049] (1) After pretreatment, saccharification, plate and frame filtration, sterilization, decolorization, ion exchange, purification and concentration of xylo-oligosaccharide production raw materials, the content of 40wt obtained with a refractive index of 60% (equal to total sugar in dry matter) % (40wt% in the total sugar of dry matter is xylo-oligosaccharides) concentrated solution of xylo-oligosaccharides, specifically with embodiment 1;

[0050] (2) Dihydrate crystalline trehalose, mannitol and gum arabic were heated and dissolved in deionized water at 70°C to obtain dihydrate crystalline trehalose solution, mannitol solution and gum arabic solution respectively. Xylan concentrated solution, dihydrate crystalline trehalose solution and mannitol solution are added to the gum arabic solution, and fully mixed; the mass ratio of the dihydrate crystalline trehalose, mannitol and arabic gum is 7:12:14.3, and the above The weight ratio of the dry matter total sugar in the xylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com