Photonic crystal nano-composite gel membrane with temperature/humidity dual responses and preparation method of photonic crystal nano-composite gel membrane

A photonic crystal and nanocomposite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low resolution of optical signals, poor visualization of color changes, slow response rate, etc., to achieve High optical signal resolution, strong visibility of color changes, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

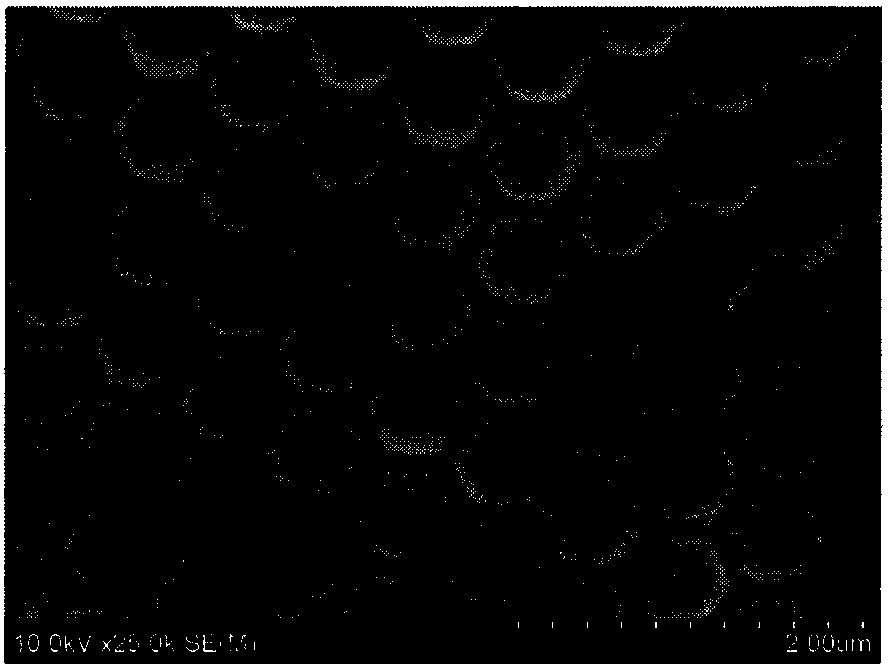

[0037] (1) Synthesis of monodisperse latex particles: In a four-necked flask equipped with a condenser, a heating device, a nitrogen protection and a stirring device, add 100 mL of deionized water, and after nitrogen deoxygenation for 35 min, add 5 mL of styrene with a trace amount Add the pipette dropwise into the four-necked flask, raise the temperature to 65°C, stir at constant temperature for 30min, then add 0.1g of ammonium persulfate into the reaction solution, N 2 React under protection for 6 hours. After the reaction, cool naturally to room temperature to obtain polystyrene monodisperse latex particles. Store in a brown glass bottle for later use;

[0038] (2) Preparation of 2D photonic crystals by the needle tip method: the polystyrene latex particles obtained in step (1) and isopropanol are formulated into a mixed solution with a mass fraction of 10 wt%, and after stirring at room temperature, use a syringe with a volume range of 2mL Drop the tip of the needle onto t...

Embodiment 2

[0043] (1) Synthesis of monodisperse latex particles: Add 100 mL of deionized water to a four-necked flask equipped with a condenser, a heating device, nitrogen protection and a stirring device, and after passing through nitrogen to remove oxygen for 30 min, add 4 mL of styrene with a trace amount Add the pipette dropwise into the four-necked flask, raise the temperature to 70°C, and stir at constant temperature for 30 minutes, then add 0.08g of ammonium persulfate into the reaction solution, N 2 React under protection for 6 hours. After the reaction, cool naturally to room temperature to obtain polystyrene monodisperse latex particles. Store in a brown glass bottle for later use;

[0044] (2) Preparation of 2D photonic crystals by the needle tip method: the polystyrene latex particles obtained in step (1) and n-propanol are formulated into a mixed solution with a mass fraction of 15 wt%, and after stirring at room temperature, use a syringe with a range of 2 mL Drop the tip o...

Embodiment 3

[0048] (1) Synthesis of monodisperse latex particles: Add 110mL of deionized water to a four-necked flask equipped with a condenser, heating device, nitrogen protection and stirring device, and after passing through nitrogen to remove oxygen for 30min, add 4.5mL of methacrylic acid Add the methyl ester dropwise into the four-necked flask with a micropipette, raise the temperature to 65°C, and stir at constant temperature for 30 minutes, then add 0.1 g of ammonium persulfate to the reaction solution, N 2 React under protection for 6 hours. After the reaction, naturally cool to room temperature to obtain polymethyl methacrylate monodisperse latex particles, and store them in a brown glass bottle for later use;

[0049] (2) Preparation of 2D photonic crystals by the needle tip method: the polymethyl methacrylate latex particles obtained in step (1) and n-butanol are formulated into a mixed solution with a mass fraction of 8wt%, and after stirring at room temperature, use a measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com