Treatment method for surfactant-containing wastewater

A surfactant and wastewater treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve the problem of low CODcr removal rate, and is conducive to large-scale popularization and application , to avoid secondary pollution, the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

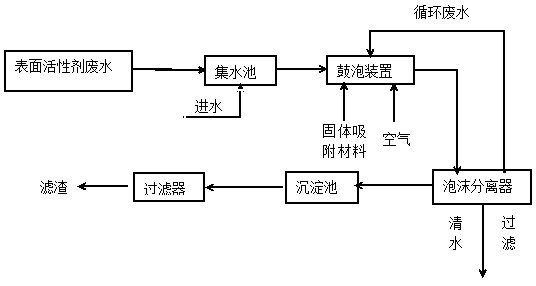

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Take the treatment of wastewater containing sodium dodecylbenzenesulfonate (SDBS) as an example.

[0028] SDBS is an anionic surfactant, which is often used in industrial production and daily life due to its advantages of good foaming, stable performance, and low price, and it is a biodegradable substance. Its wide use has caused serious damage to the water environment. pollution.

[0029] Weigh a certain amount of SDBS and stir it in a 1000 mL beaker to fully dissolve it, pour the solution into the sump, take a certain amount of tap water in the sump, and make a SDBS solution with a mass fraction of 0.5%, and mix it evenly Reserved as simulated wastewater for later use.

[0030] SDBS is an anionic surfactant that makes the wastewater negatively charged, and adsorbing material particles with positively charged surfaces are added to the process (for example, the isoelectric point of calcium carbonate is pH 9.5, so it is positively charged when the pH value is...

Embodiment 2

[0032] Example 2: Take the treatment of wastewater containing sodium dodecyl sulfate (SDS) as an example.

[0033] SDS is an anionic surfactant, which is widely used in detergent and textile industries due to its good detergency, emulsification, and foaming properties, but it is slightly toxic to the human body.

[0034] Weigh a certain amount of SDS and stir it in a 1000 mL beaker to fully dissolve it, pour the solution into the sump, take a certain amount of tap water in the sump, and make an SDS solution with a mass fraction of 0.5%, and mix it evenly Reserved as simulated wastewater for later use.

[0035] SDS is an anionic surfactant that makes wastewater negatively charged. Adsorbent particles with positively charged surfaces are added to the process (for example, the isoelectric point pH of calcium carbonate is 9.5, so it is positively charged when the pH value is lower than 9.5). Add 3000 mesh calcium carbonate particles into the bubbling device at 0.5g / L, use sodium ...

Embodiment 3

[0037] Embodiment 3: Take the treatment of wastewater containing nonylphenol polyoxyethylene ether (NPEO) as an example.

[0038] NPEO is a nonionic surfactant that, when released into the environment, rapidly decomposes nonylphenol (NP), an environmental hormone. NP can simulate estrogen, affect the sexual development of organisms, interfere with the endocrine of organisms, and have toxicity to the reproductive system. At the same time, nonylphenol (NP) can continuously accumulate in organisms through the food chain, so studies have shown that even if the emission concentration is very low, it is extremely harmful. Therefore, NPEO is not suitable for oxidative degradation treatment and should be separated and recycled.

[0039] Weigh a certain amount of NPEO and stir it in a 1000 mL beaker to fully dissolve it, pour the solution into the sump, take a certain amount of tap water in the sump, and make a 0.5% NPEO solution by mass fraction, mix it evenly Reserved as simulated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com