Barium strontium titanate dielectric material for microwave tuning device

A technology of barium strontium titanate and dielectric materials, which is applied in the field of barium strontium titanate dielectric materials for microwave tuning devices, and can solve problems such as limiting the application of BST materials, high dielectric loss, dielectric adjustability, and other electrical performance declines , to achieve controllable cost, high dielectric constant, and improved dielectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one of the present invention is:

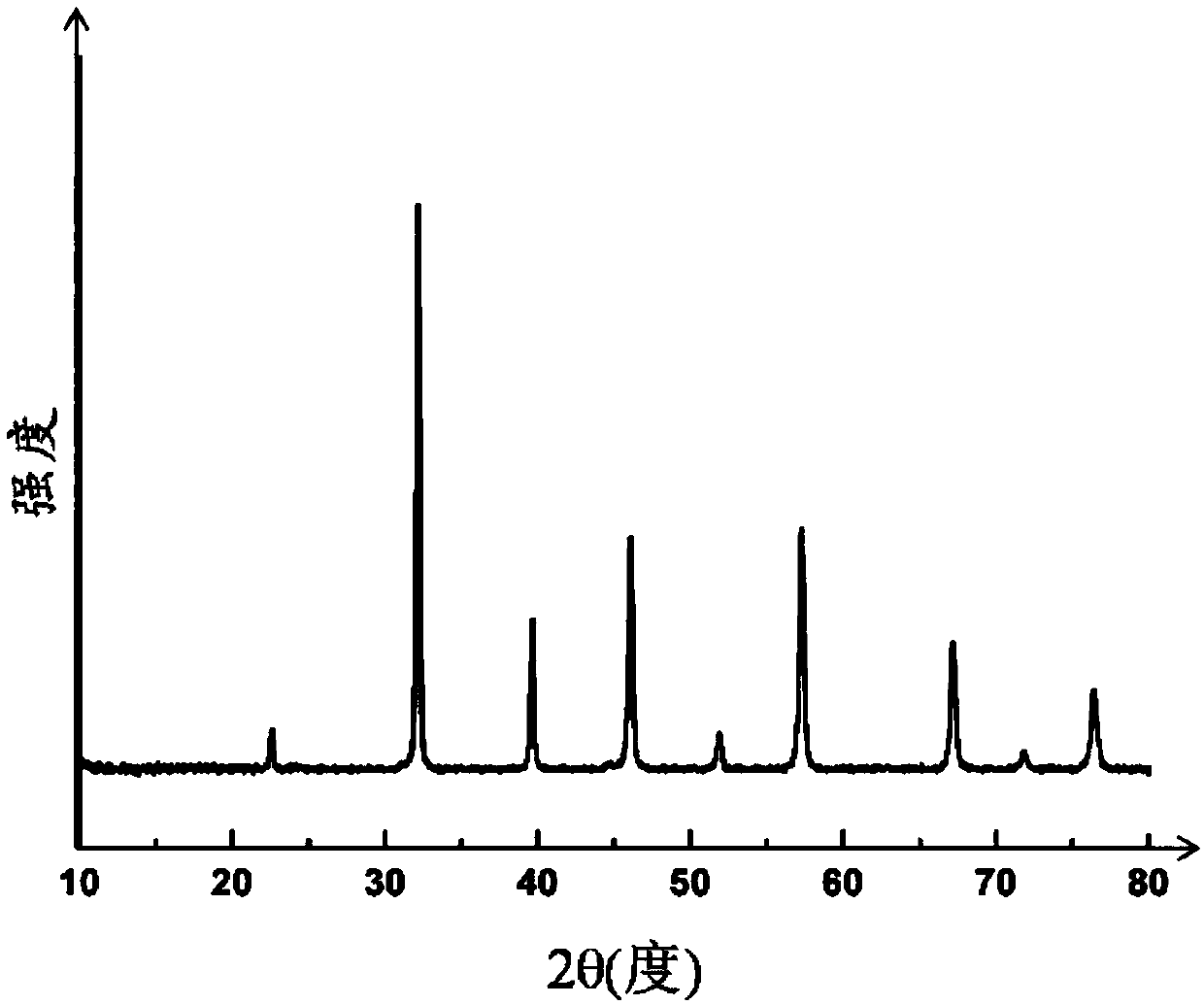

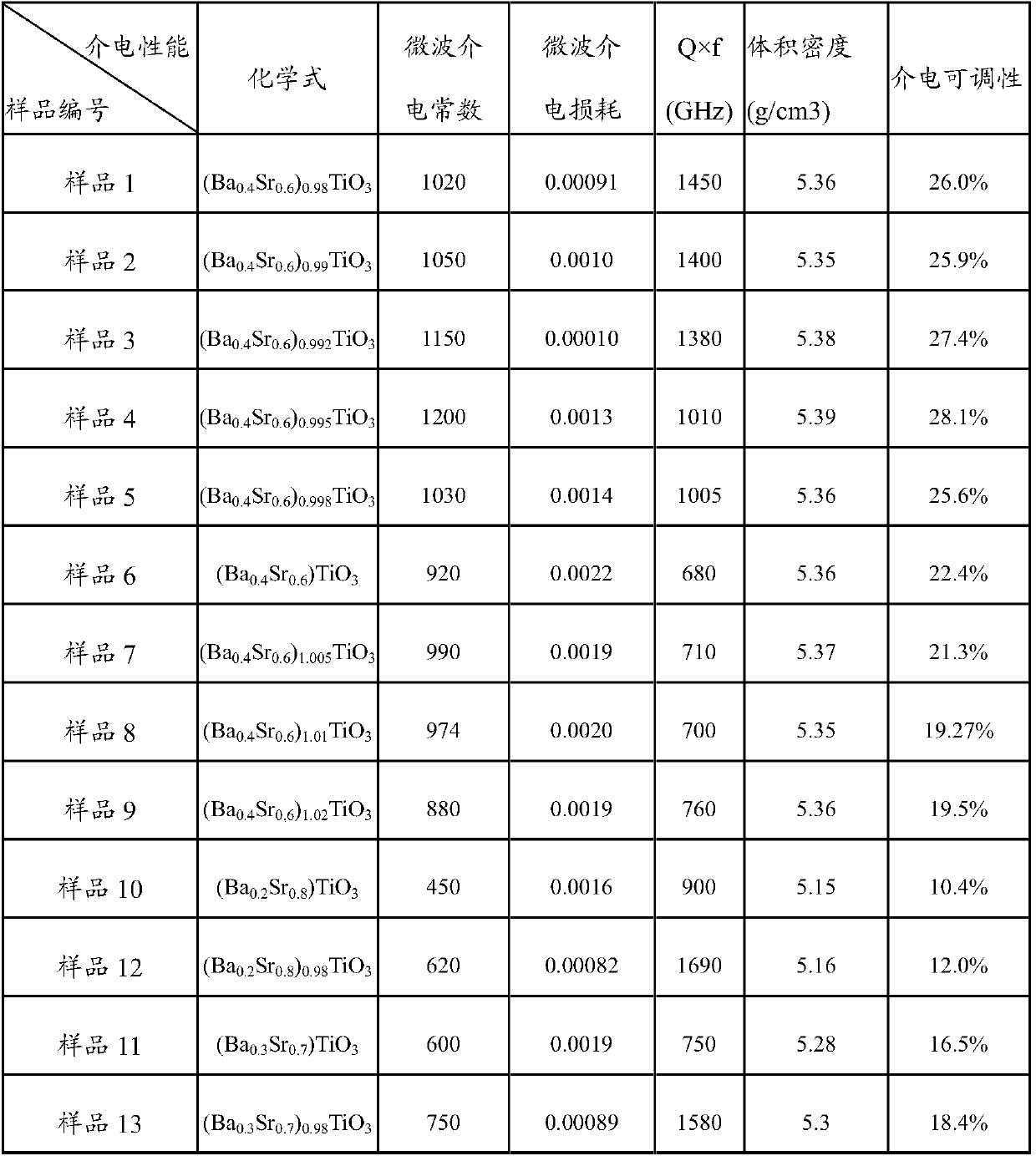

[0025] A strontium barium titanate dielectric material for microwave tuning devices, the chemical formula of the strontium barium titanate dielectric material is (Ba x Sr 1-x ) 1+δ TiO 3 , where x=0.2~0.4, δ=-0.02~0.02. Preferably, x=0.4, δ=-0.02~-0.002. figure 1 The XRD pattern of the BST material of this example, from figure 1 It can be seen that the diffraction peak near 45° is a single peak shape, and there is no phenomenon of splitting peaks, indicating that the BST material has a single cubic perovskite structure. figure 2 The SEM image of the BST material of this example is obtained by figure 2 It can be seen that the BST material has a single grain shape, the grain growth is intact, and no obvious impurity phase is observed inside the grain and at the grain boundary.

Embodiment 2

[0027] Embodiment 2 of the present invention is the preparation method of BST material, including:

[0028] (1) with (Ba 0.4 Sr 0.6 ) 0.98 TiO 3 The chemical formula composition of BaTiO was weighed separately 3 (purity 99.5%) and SrTiO 3 (99.5% purity) raw material.

[0029] (2) Using absolute ethanol as the ball-milling medium, the weighed raw materials were added to the ball-milling tank, and the horizontal wet ball-milling process was used for mixing and ball-milling for 24 hours. After discharging, it is dried in an oven at 80°C, and then pre-fired in a muffle furnace at 1150°C for 2 hours to obtain BST ceramic powder.

[0030] (3) adding a polyvinyl alcohol (PVA) aqueous solution accounting for 2wt% of the mass of the powder to the BST ceramic powder obtained in step (2) for granulation, after passing through an 80-mesh sieve, under a uniaxial pressure of 175MPa, the BST ceramic green body was obtained. Then, the ceramic body was kept at 600°C for 2 hours for deb...

Embodiment 3

[0032] Embodiment 3 of the present invention is the preparation method of BST material, including:

[0033] (1) with (Ba 0.4 Sr 0.6 ) 0.99 TiO 3 The chemical formula composition of BaTiO was weighed separately 3 (purity 99.5%) and SrTiO 3 (99.5% purity) raw material.

[0034] (2) Using absolute ethanol as the ball-milling medium, the weighed raw materials were added to the ball-milling tank, and the horizontal wet ball-milling process was used for mixing and ball-milling for 24 hours. After discharging, it is dried in an oven at 80°C, and then pre-fired in a muffle furnace at 1150°C for 2 hours to obtain BST ceramic powder.

[0035] (3) adding a polyvinyl alcohol (PVA) aqueous solution accounting for 2wt% of the mass of the powder to the BST ceramic powder obtained in step (2) for granulation, after passing through an 80-mesh sieve, under a uniaxial pressure of 175MPa, the BST ceramic green body was obtained. Then, the ceramic body was kept at 600°C for 2 hours for deb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com