A fluorescent anti-counterfeiting composite material with adjustable wavelength and its preparation method

A composite material, fluorescence technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, selenium/tellurium compounds, etc. The problem is to achieve the effect of simple preparation steps, mild synthesis conditions, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing a fluorescent anti-counterfeiting composite material with adjustable wavelength, the method comprising:

[0039] Step 1: preparing a cadmium telluride quantum dot solution;

[0040] Step 2: preparing polyurethane prepolymer;

[0041] Step 3: Add the cadmium telluride quantum dot solution obtained in step 1 to the polyurethane prepolymer obtained in step 2 for emulsification under stirring to obtain an aqueous polyurethane dispersion, place the solvent at room temperature to completely evaporate and then vacuum dry to obtain Fluorescent anti-counterfeiting composite material with tunable wavelength.

[0042] According to the present invention, the cadmium telluride quantum dot solution is prepared first, preferably as follows: add the cadmium source, the ligand, and water into the reaction vessel at room temperature, adjust the pH value, add the tellurium source under anaerobic conditions, and heat to reflux at ...

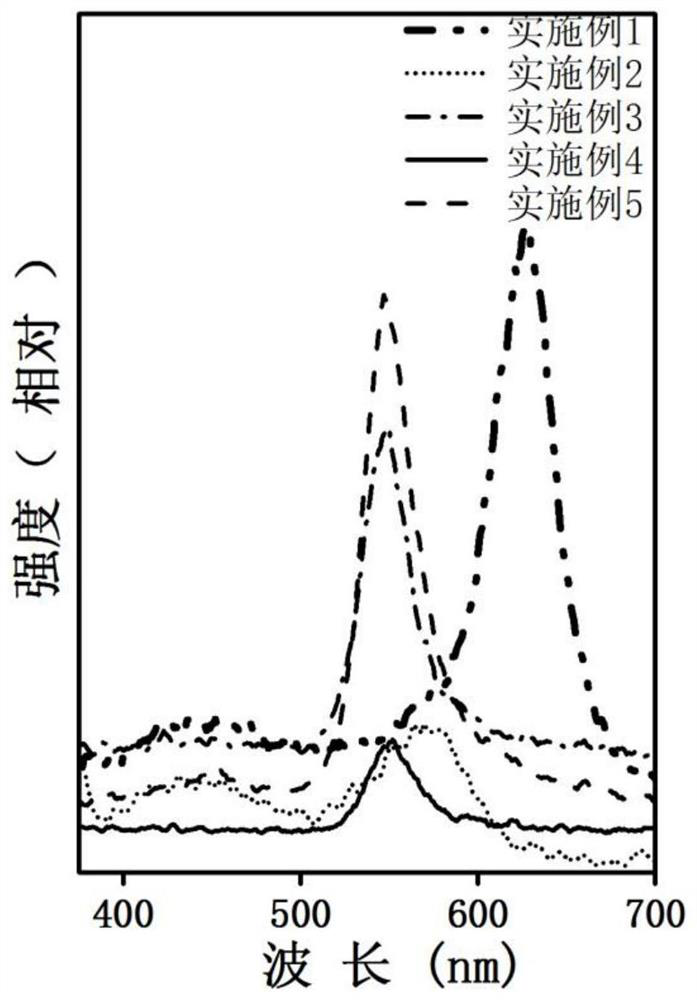

Embodiment 1

[0050] 1) Preparation of cadmium telluride quantum dot solution:

[0051] Dissolve 0.001mol cadmium chloride and 0.004mol mercaptoethylamine in 90mL water, adjust the pH value to 5.6, and add 0.0003molL sodium hydride telluride solution under anaerobic conditions, heat and reflux at 150°C for 3h, then concentrate by rotary evaporation to 10mL Cadmium telluride solution.

[0052] 2) Preparation of polyurethane prepolymer:

[0053] Add 0.020mol polyoxypropylene diol, 0.009mol dimethylol butyric acid and 0.038mol toluene diisocyanate to the reaction flask, heat and stir at 80°C for 40 minutes, then cool down to room temperature, add 0.007mol acetone and stir for 2 minutes, then add 0.008mol triethylamine, continue to react for 10min, finally add 0.002molL γ-aminopropyltriethoxysilane, stir for 5min, and obtain the polyurethane prepolymer.

[0054] 3) Preparation of fluorescent anti-counterfeiting composite materials with tunable wavelength:

[0055] Add the cadmium telluride q...

Embodiment 2

[0058] 1) Preparation of cadmium telluride quantum dot solution:

[0059] Dissolve 0.001mol cadmium chloride and 0.004mol mercaptoethylamine in 90mL water, adjust the pH value to 5.6, and add 0.0003moL sodium telluride hydride solution under anaerobic conditions, heat and reflux at 150°C for 1 hour, then concentrate by rotary evaporation to 10mL Cadmium telluride solution.

[0060] 2) Preparation of polyurethane prepolymer:

[0061] Add 0.020mol polyoxypropylene diol, 0.009mol dimethylol butyric acid and 0.038mol toluene diisocyanate to the reaction flask, heat and stir at 70°C for 80 minutes, then cool down to room temperature, add 0.007mol acetone and stir for 5 minutes, then add 0.008mol triethylamine, continue to react for 30min, finally add 0.002molL γ-aminopropyltriethoxysilane, stir for 10min, and obtain the polyurethane prepolymer.

[0062] 3) Preparation of fluorescent anti-counterfeiting composite materials with tunable wavelength:

[0063] Add the cadmium telluri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| quantum dot | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com