Rare earth element doped titanium-based mesoporous titanium dioxide platinized catalyst material and preparation method and application thereof

A technology of mesoporous titanium dioxide and rare earth elements, applied in the direction of electrode, electrolysis process, electrode shape/type, etc., can solve the problems of increased cost, high price, low platinum content, etc., and achieve easy operation, improved electrode stability, and improved catalytic performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Cut 30mm×4mm×1mm TA1-type titanium strip as the substrate, and polish it with sandpaper of 80 mesh, 200 mesh, 600 mesh, 1000 mesh, 1200 mesh and 2000 mesh in sequence to make the surface smooth and silvery white , followed by ultrasonic cleaning with secondary water, acetone and absolute ethanol for 10 minutes, and then corrosion treatment with a mixed solution of ethylene glycol and HF, the volume ratio of ethylene glycol and HF is 6:1, until no Metallic luster, finally ultrasonic treatment with acetone and absolute ethanol for 10 minutes;

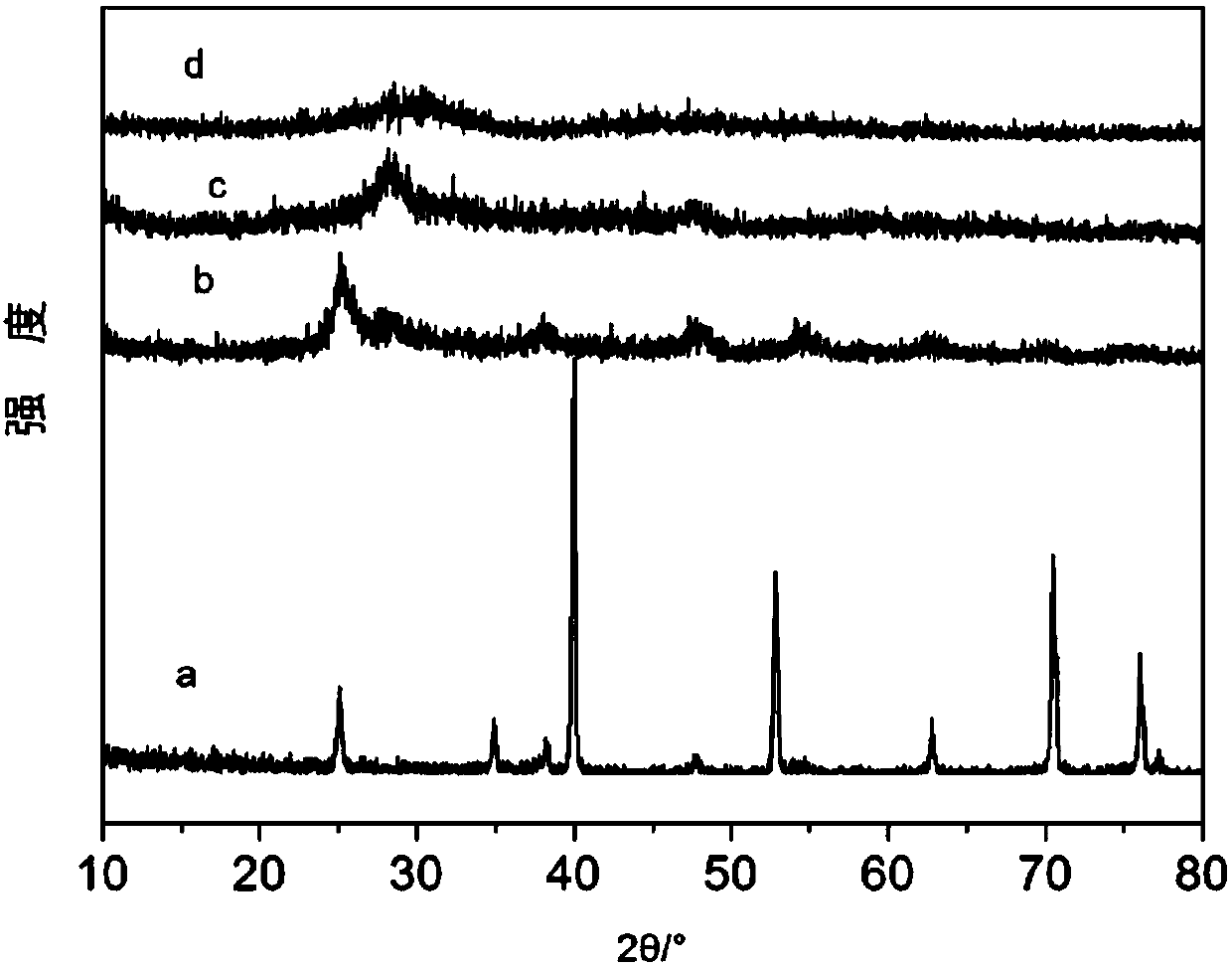

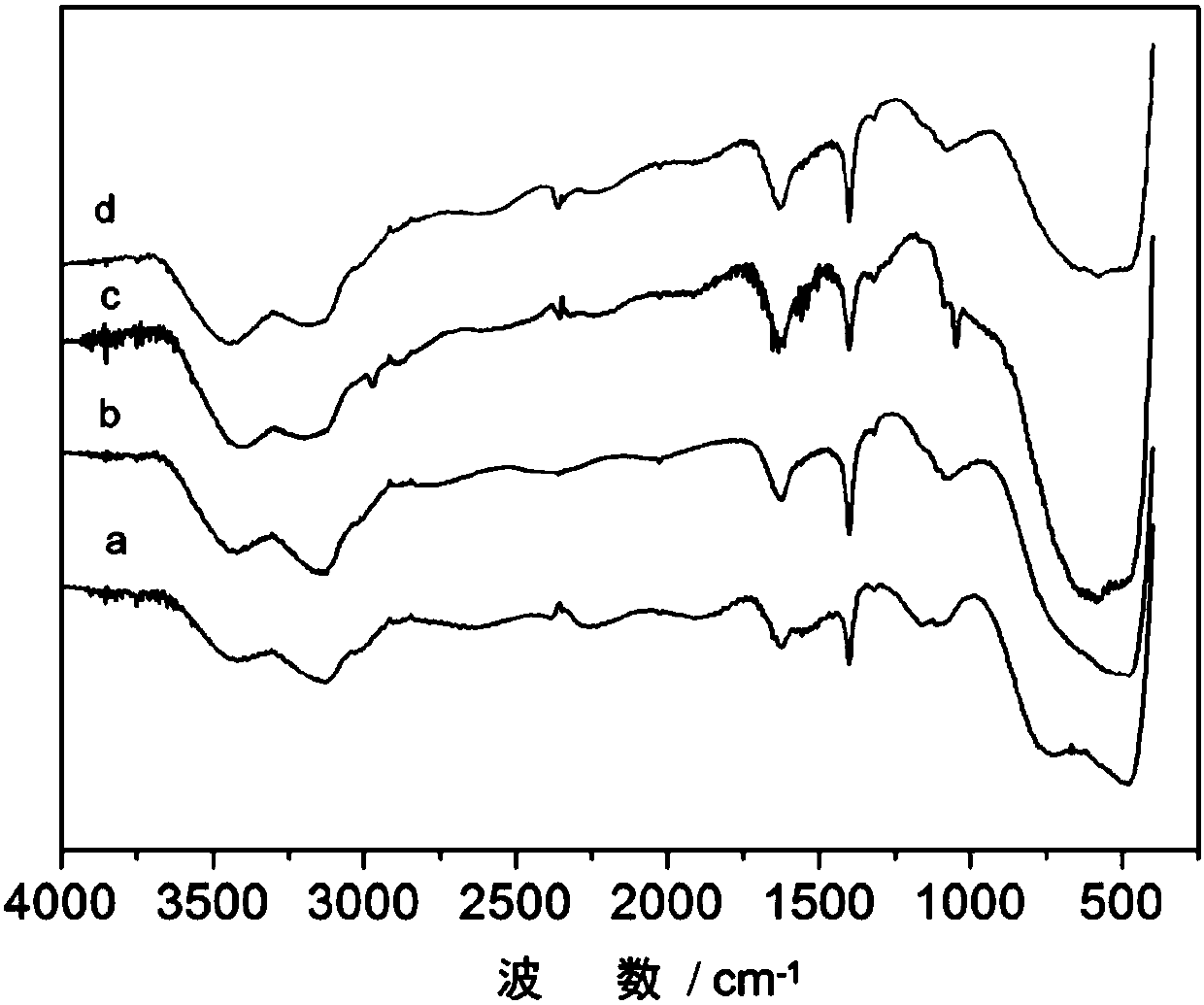

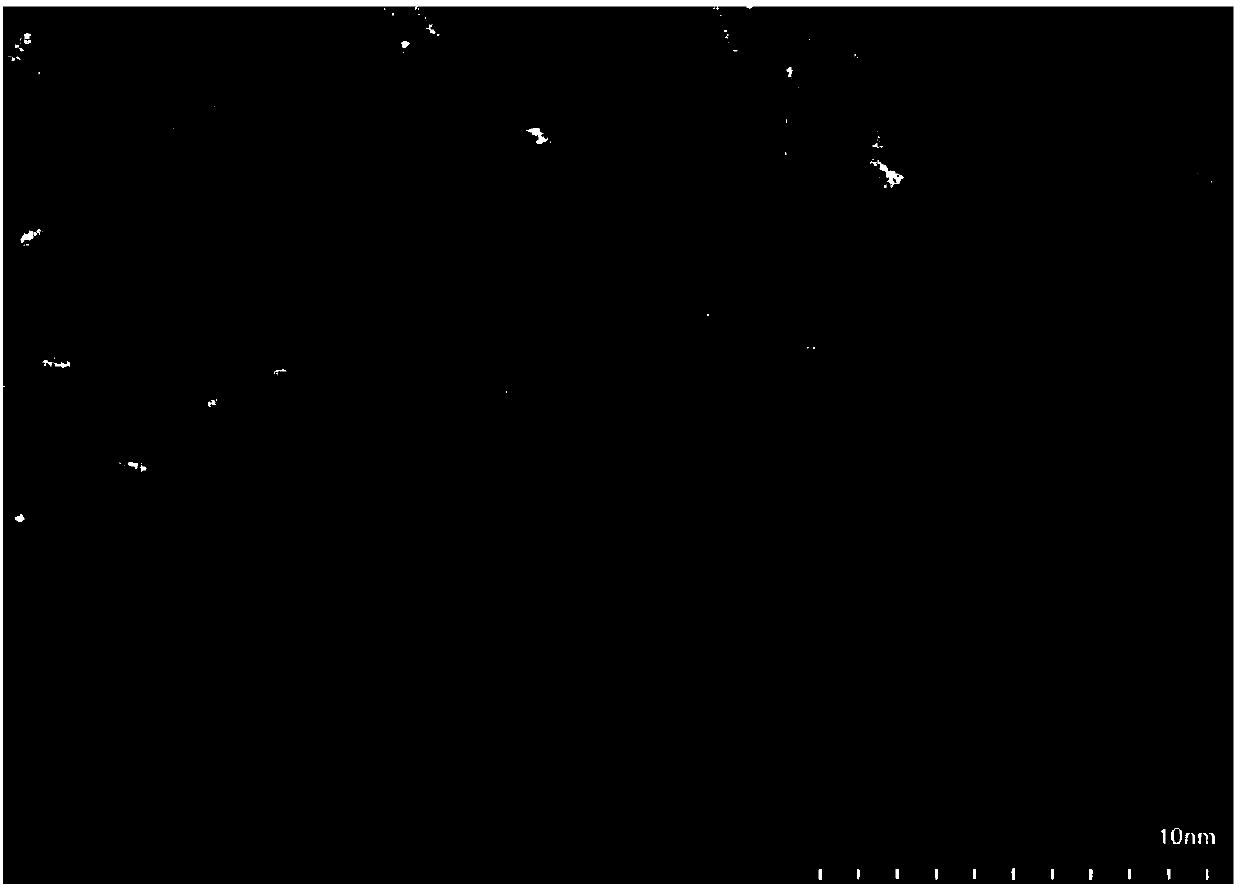

[0048] (2) Stir 0.342g of P123 template in 50mL of n-butanol until dissolved, and add a ternary mixed solution of n-butanol, acetylacetone and tetrabutyl titanate in a volume ratio of 4:0.4:1, Add dropwise nitric acid to adjust the pH of the solution to 2, add dropwise a cerium nitrate solution with a concentration of 0.001mol / L, and stir at 25°C for 12 hours to form a sol; the molar ratio of P123 template agent to tetrabutyl t...

Embodiment 2

[0058] (1) Cut 30mm×4mm×1mm TA1-type titanium strip as the substrate, and polish it with sandpaper of 80 mesh, 200 mesh, 600 mesh, 1000 mesh, 1200 mesh and 2000 mesh in sequence to make the surface smooth and silvery white , followed by ultrasonic cleaning with secondary water, acetone and absolute ethanol for 10 minutes, and then corrosion treatment with a mixed solution of ethylene glycol and HF, the volume ratio of ethylene glycol and HF is 6:1, until no Metallic luster, finally ultrasonic treatment with acetone and absolute ethanol for 10 minutes;

[0059] (2) Stir 0.342g of P123 template in 50mL of n-butanol until dissolved, and add a ternary mixed solution of n-butanol, acetylacetone and tetrabutyl titanate in a volume ratio of 4:0.4:1, Add dropwise nitric acid to adjust the pH of the solution to 2, add dropwise a cerium nitrate solution with a concentration of 0.001mol / L, and stir at 25°C for 12 hours to form a sol; the molar ratio of P123 template agent to tetrabutyl t...

Embodiment 3

[0064] (1) Cut 30mm×4mm×1mm TA1-type titanium strip as the substrate, and polish it with sandpaper of 80 mesh, 200 mesh, 600 mesh, 1000 mesh, 1200 mesh and 2000 mesh in sequence to make the surface smooth and silvery white , followed by ultrasonic cleaning with secondary water, acetone and absolute ethanol for 10 minutes, and then corrosion treatment with a mixed solution of ethylene glycol and HF, the volume ratio of ethylene glycol and HF is 6:1, until no Metallic luster, finally ultrasonic treatment with acetone and absolute ethanol for 10 minutes;

[0065] (2) Stir 0.342g of P123 template in 50mL of n-butanol until dissolved, and add a ternary mixed solution of n-butanol, acetylacetone and tetrabutyl titanate in a volume ratio of 4:0.4:1, Add dropwise nitric acid to adjust the pH of the solution to 2, add dropwise a cerium nitrate solution with a concentration of 0.001mol / L, and stir at 25°C for 12 hours to form a sol; the molar ratio of P123 template agent to tetrabutyl t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com