Cross-linked self-adhesive glue type polymer waterproof roll and preparation method thereof

A polymer waterproof and self-adhesive technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve the problems of poor aging resistance, insufficient bonding, and poor water impermeability, etc., to achieve Strong cohesiveness, easy lapping, and the effect of preventing water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

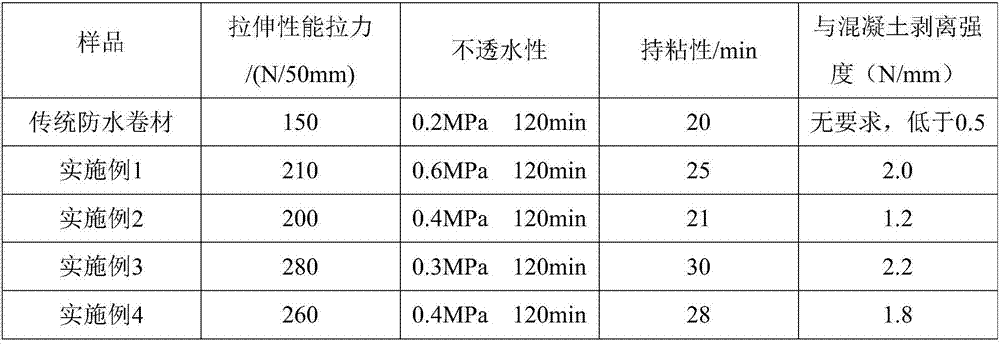

Examples

Embodiment 1

[0028] A cross-linked self-adhesive polymer waterproof membrane, including a bimodal high-density polyethylene film and a self-adhesive film coated on the film, the self-adhesive film includes the following raw material groups in parts by mass Ingredients: 60 parts of acrylate pressure sensitive adhesive, 18 parts of carboxylated styrene-butadiene rubber, 4 parts of naphthenic acid, 7 parts of aromatic hydrocarbon resin, 3 parts of naphthalene sulfonate, 5 parts of polyacrylic acid, 2 parts of peracetic acid, 1 part gingerol;

[0029] The preparation method of the cross-linked self-adhesive polymer waterproof membrane, the steps are as follows:

[0030] Step 1: Prepare self-adhesive film

[0031] First, weigh each raw material component according to the mass ratio, respectively add acrylate pressure-sensitive adhesive, naphthenic acid, and aromatic hydrocarbon resin into the reaction tank, raise the temperature to 180°C, and then add carboxylated styrene-butadiene rubber, und...

Embodiment 2

[0035] A cross-linked self-adhesive polymer waterproof membrane, including a bimodal high-density polyethylene film and a self-adhesive film coated on the film, the self-adhesive film includes the following raw material groups in parts by mass Substances: 67 parts of acrylate pressure-sensitive adhesive, 15 parts of carboxylated styrene-butadiene rubber, 3 parts of naphthenic acid, 6 parts of aromatic hydrocarbon resin, 2.5 parts of naphthalene-based sulfonate, 3.5 parts of polymethacrylic acid, benzoic acid peroxide 2 parts, 1 part of gingerol oxime;

[0036] The preparation method of the cross-linked self-adhesive polymer waterproof membrane, the steps are as follows:

[0037] Step 1: Prepare self-adhesive film

[0038] First, weigh each raw material component according to the mass ratio, respectively add acrylate pressure-sensitive adhesive, naphthenic acid, and aromatic hydrocarbon resin into the reaction tank, raise the temperature to 180°C, and then add carboxylated sty...

Embodiment 3

[0042] A cross-linked self-adhesive polymer waterproof membrane, including a bimodal high-density polyethylene film and a self-adhesive film coated on the film, the self-adhesive film includes the following raw material groups in parts by mass Subdivision: 70 parts of acrylate pressure sensitive adhesive, 14 parts of carboxylated styrene-butadiene rubber, 2 parts of naphthenic acid, 5 parts of aromatic hydrocarbon resin, 2 parts of naphthalene-based sulfonate, 2 parts of polymethacrylic acid, hydroxyl-terminated polybutylene 3.5 parts of diene, 1 part of peroxybenzoic acid, 0.5 part of gingerol;

[0043] The preparation method of the cross-linked self-adhesive polymer waterproof membrane, the steps are as follows:

[0044] Step 1: Prepare self-adhesive film

[0045]First, weigh each raw material component according to the mass ratio, respectively add acrylate pressure-sensitive adhesive, naphthenic acid, and aromatic hydrocarbon resin into the reaction tank, raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com