Cooking film with low temperature-resistant and anti-fogging properties and preparation method thereof

A cooking film, low temperature resistant technology, applied in chemical instruments and methods, types of packaging items, special packaging items, etc., can solve the problems of unclear food freshness, insufficient mechanical strength and toughness, ink easily falling into food, etc. Achieve the effect of good self-cleaning ability, good anti-fog performance and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

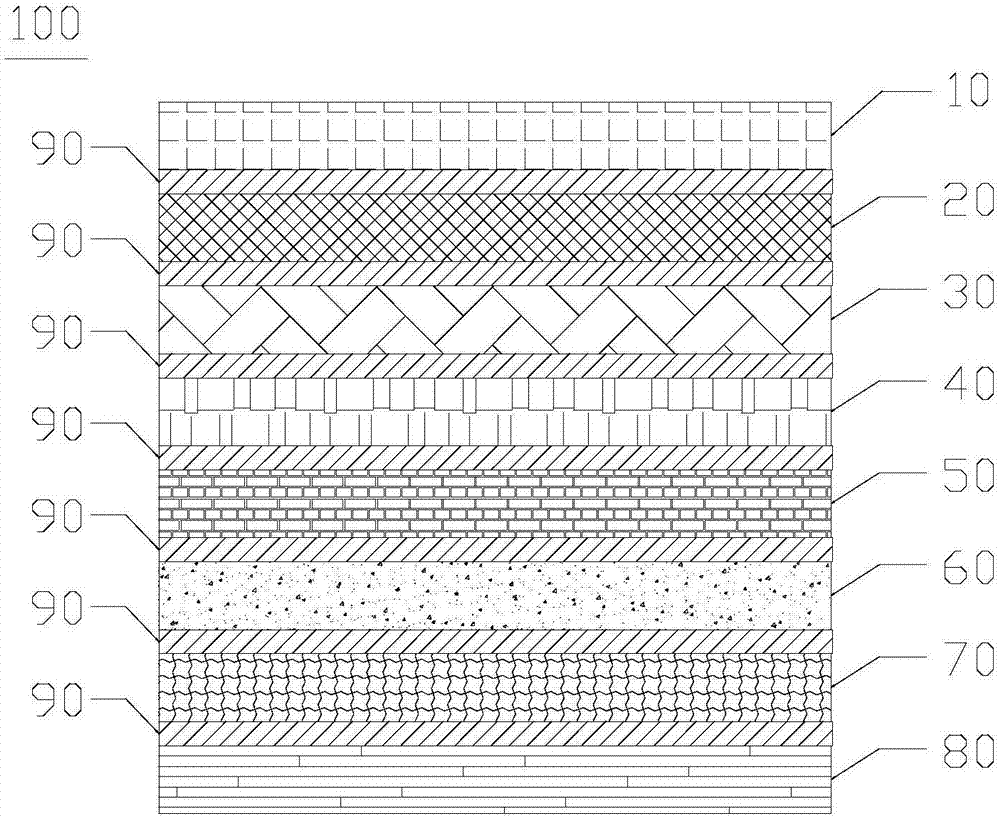

Image

Examples

Embodiment 1

[0126] 1. Take 8.9 parts of gelatin and 80 parts of water into a bottle and mix well. Let it stand for 15 minutes to 2 hours, until the gelatin is completely swollen, heat it in a water solution at 65°C, while stirring continuously at a speed of 40-50 per minute, until the gelatin is completely dissolved (about 10 minutes).

[0127] 2. Maintain a constant temperature of 65°C, add 1 part of formaldehyde, valeraldehyde or acetaldehyde, 10 parts of sodium chloride or glycerin and 0.1 part of sodium azide, stir evenly, and then prepare it as an anti-fogging agent.

[0128] 3. Put this anti-fogging agent into a pressure sprayer quickly, spray it evenly on the surface of glass or mirror, and form an anti-fogging film after cooling. (maximum strength reached after four days)

Embodiment 2

[0130] Get 11.7 parts of gelatin, 66 parts of anhydrous liquid ammonia, 2 parts of sulfuryl fluoride or hexamine, 20 parts of magnesium chloride and 0.3 part of propylene glycol. Dissolve in a pressure vessel and shake well. Spray the anti-fog agent evenly on the surface of the glass or mirror with self-nozzle, and form an anti-fog film after drying.

Embodiment 3

[0132] 1. Take 8 parts of gelatin, 60 parts of acetic acid and 30 parts of phosphoric acid, fully swell, heat and mix well. Then add 0.5 parts of chromium alum, 1.5 parts of ethylene glycol or glycerin to prepare an anti-fogging agent.

[0133] 2. Dip the anti-fog agent with a roller brush, evenly roll it on the surface of the glass or mirror, and form an anti-fog film after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com