Hydrocracking method adopting blending of coal tar

A technology for hydrocracking and tar, which is applied in the field of hydrocracking of blended coal tar, and can solve the problems of limited yield of naphtha, low quality of diesel oil and tail oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

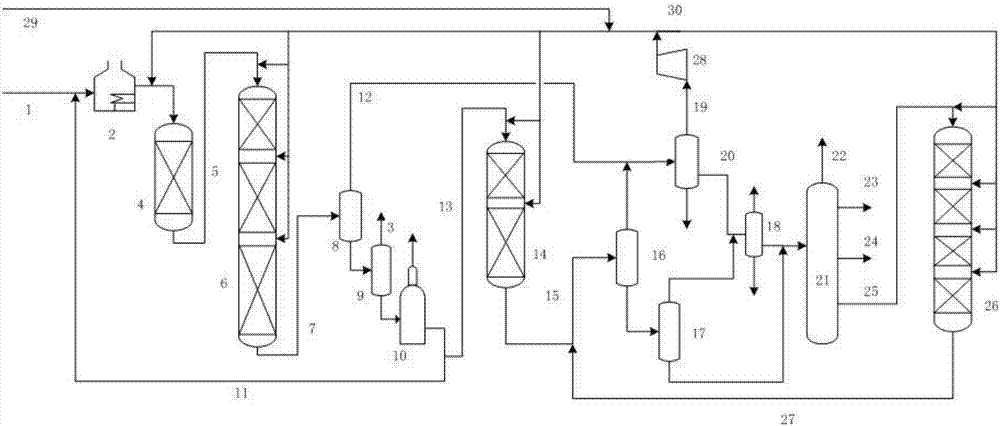

Method used

Image

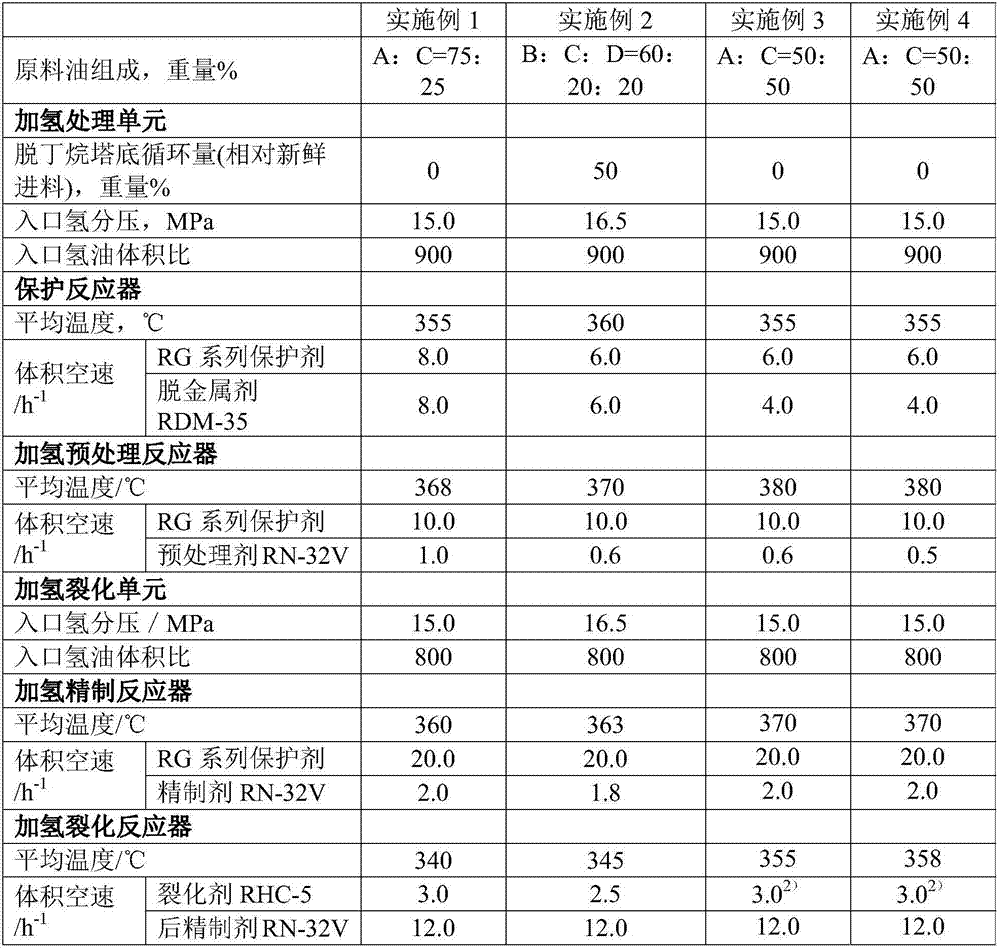

Examples

preparation example Construction

[0047] According to a preferred specific implementation, in the hydrocracking catalyst, the preparation method of the carrier includes the following steps:

[0048] (1) Beta type molecular sieve is mixed with weakly acidic silica-alumina, pseudo-boehmite, peptizer, lubricant and water to obtain a mixture, and the consumption of each component makes the amount of substance of peptizer in the mixture and The total weight ratio of powder is 0.28×10 -4 ~4.8×10 -4 mol / g, the ratio of the weight of water to the amount of peptizer is 2.0×10 3 ~30×10 3 g / mol, the total weight of the powder is the sum of the weight of the Beta type molecular sieve, pseudo-boehmite and weakly acidic silica-alumina, and the amount of the peptizer substance refers to the metered H proton mole in the peptizer number; the lubricant is squash powder and / or graphite, based on the total weight of the powder, the ratio of the lubricant to the total weight of the powder is: (1~9):100;

[0049] (2) kneading, ...

preparation example 1

[0086] Preparation Example 1: Preparation of Hierarchical Porous Hydrocracking Catalyst C-1 Containing Silicon and Aluminum

[0087] 236.5 grams of pseudo-boehmite PB1 (dry basis 0.74) and 122 grams of molecular sieve Beta (produced by Sinopec Catalyst Jianchang Branch, silicon-aluminum ratio 27, pore volume 0.395mL / g, dry basis 0.82), 16 grams of scallop powder , 78.9 grams of weakly acidic silicon-alumina (produced by German Condea company, trade name Sira-40, pore volume 0.88mL / g, specific surface 468m 2 / g, silicon dioxide weight content 40%, infrared B acid acidity value 0.04mmol / g, dry basis 0.76), 7.7mL concentrated nitric acid with a purity of 65%, and 310mL deionized water are mixed evenly, and extruded into a circumscribed circle with a diameter of 1.6 The trefoil strips of 1.2 mm were dried at 120° C. for 3 hours, and then calcined at 600° C. for 3 hours to obtain a carrier. The composition is shown in Table 2.

[0088] After cooling to 25°C, get 100 grams of carri...

preparation example 2

[0090] Preparation Example 2: Preparation of Silicon-Al-Containing Hierarchical Hydrocracking Catalyst C-2

[0091] With 233.3 grams of pseudo-boehmite SB (dry basis 0.75, the dry basis measurement method is to put a certain amount of original powder into a crucible with a cover and put it in a muffle furnace, heat up to 700 ° C and keep the temperature for 1 hour, and calculate the remainder with the original Powder ratio, the same below) and 122 grams of molecular sieve Beta (produced by Sinopec Catalyst Jianchang Branch, silicon-aluminum ratio 27, pore volume 0.395mL / g, dry basis 0.82), 78.9 grams of weakly acidic silicon-aluminum (produced by German Condea company, Product name Sira-40, pore volume 0.88ml / g, specific surface area 468m 2 / g, silica weight content 40%, infrared B acid acidity value 0.04mmol / g, dry basis 0.76), 11 grams, 13.7mL purity are the concentrated nitric acid of 65% (molar concentration is 14.4mol / L, The same below), 226.8mL of deionized water were m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com