Preparation method of micro-encapsulation nanometer hybridized microspheres

A microsphere and microfluidic chip technology, which is applied in the field of preparation of micro-encapsulated nano-hybrid microspheres, can solve the problems of cumbersome preparation process, excessively large particle size of microspheres, inconvenient for controllable embolism, etc., and achieves a simple preparation process. , Process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

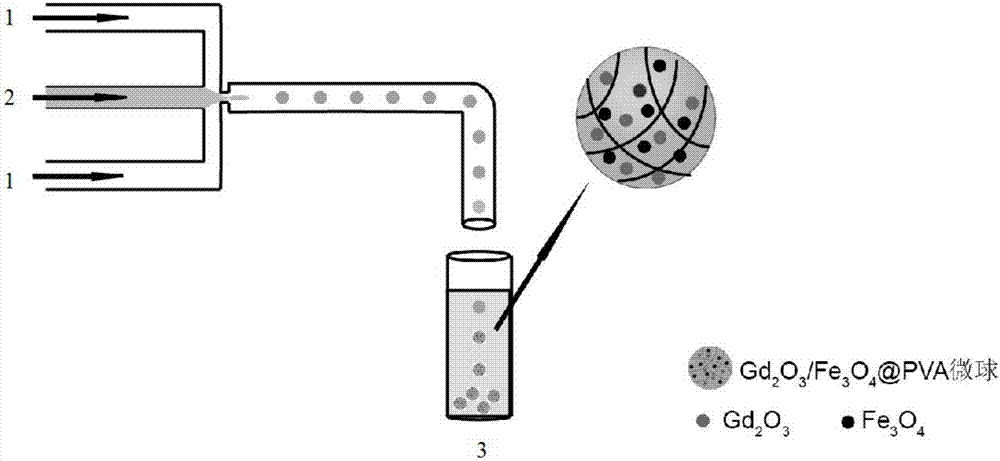

[0033] A method for preparing microencapsulated nanohybrid microspheres provided in the embodiment of the present invention adopts droplet microfluidic technology, and specifically includes the following steps:

[0034] (1) Prepare the oil phase: mix the surfactant and the continuous phase matrix uniformly to get final product. The above-mentioned surfactant is a non-ionic surfactant, preferably Span 80, and its content is between 1.5-5wt / V%. The continuous phase matrix is preferably non-polar high-boiling organic solvents such as liquid paraffin, salad oil, and silicone oil;

[0035] (2) Prepare the water phase: dissolve the trivalent gadolinium salt and / or iron salt in the PVA aqueous solution, mix evenly, it is the water phase, the above-mentioned polyvinyl alcohol concentration is 4-10.0wt%, and the above-mentioned trivalent gadolinium salt is water-soluble One of the water-soluble trivalent gadolinium salts such as nitrate, chloride and sulfate, Gd 3+ The concentration...

Embodiment 1

[0043] A method for preparing microencapsulated nanohybrid microspheres, prepared by using a microfluidic chip, comprising the following steps:

[0044] (1) Preparation of oil phase: add 0.75 g of Span 80 to 50 mL of liquid paraffin, and mix well to obtain a liquid paraffin oil phase containing 1.5 wt / V% Span 80.

[0045] (2) Prepare the water phase: first prepare a 4.0wt% PVA aqueous solution, and add a certain amount of GdCl 3 , so that the concentration is 100mmol / L, which is the water phase.

[0046] (3) Prepare alkaline receiving solution: prepare 0.5 mol / L NaOH ethanol solution.

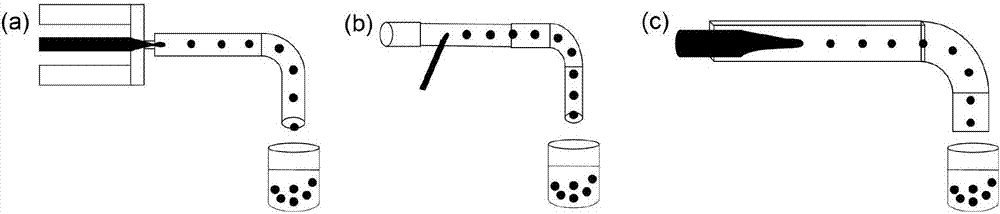

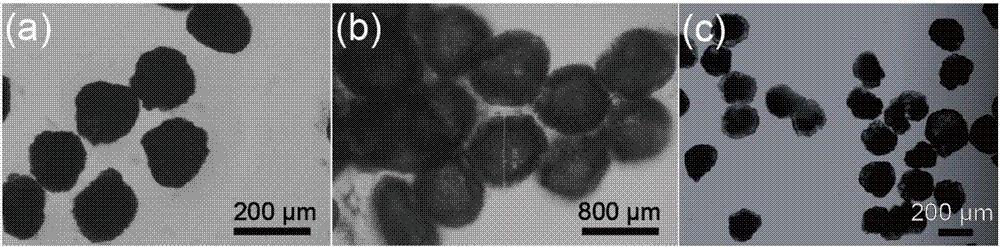

[0047] (4) Preparation of micro-encapsulated PVA microspheres by microfluidic method: the water phase prepared in step (2) and the oil phase prepared in step (1) were respectively loaded into a 2mL syringe (Bidey Medical Instrument Co., Ltd.) and a 10mL syringe ( In Shanghai Jinta Medical Equipment Co., Ltd.), under the push injection of the micro-injection pump, the flow rate of the oil phas...

experiment example 2

[0053] A method for preparing microencapsulated nanohybrid microspheres, prepared by using a microfluidic chip, comprising the following steps:

[0054] (1) Prepare the oil phase: prepare the salad oil oil phase containing 2.5wt / V% Span 80.

[0055] (2) Preparation of water phase: first prepare 7.5wt% PVA aqueous solution, add a certain amount of FeCl 3 and FeCl 2 , so that the concentration is 50mmol / L, which is the water phase.

[0056] (3) Prepare alkaline receiving solution: prepare 1.0 mol / L NaOH aqueous solution.

[0057] (4) Preparation of micro-encapsulated PVA microspheres by microfluidic method: the water phase prepared in step (2) and the oil phase prepared in step (1) were respectively loaded into a 2mL syringe (Bidey Medical Instrument Co., Ltd.) and a 10mL syringe ( Shanghai Jinta Medical Equipment Co., Ltd.), under the push injection of the micro-injection pump, the flow rate of the oil phase is set to 8000 μL / h, and the flow rate of the water phase is 4000 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com