Acid flue gas washing wastewater treatment method and use thereof

A waste water treatment and waste water technology, applied in the field of waste water treatment, acid flue gas washing waste water treatment, can solve the problems of reducing metal cation and ammonia nitrogen removal rate, ammonia gas escape and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

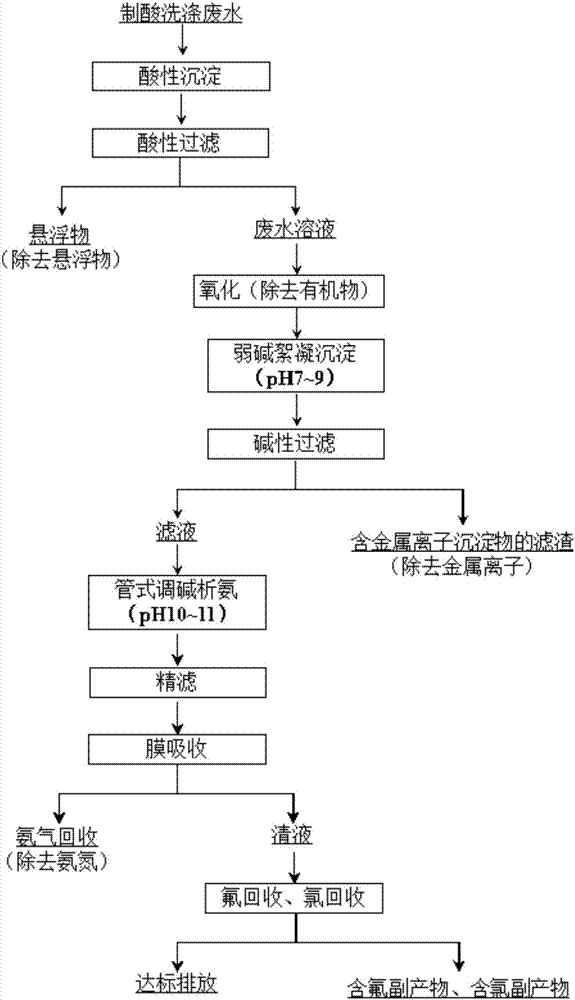

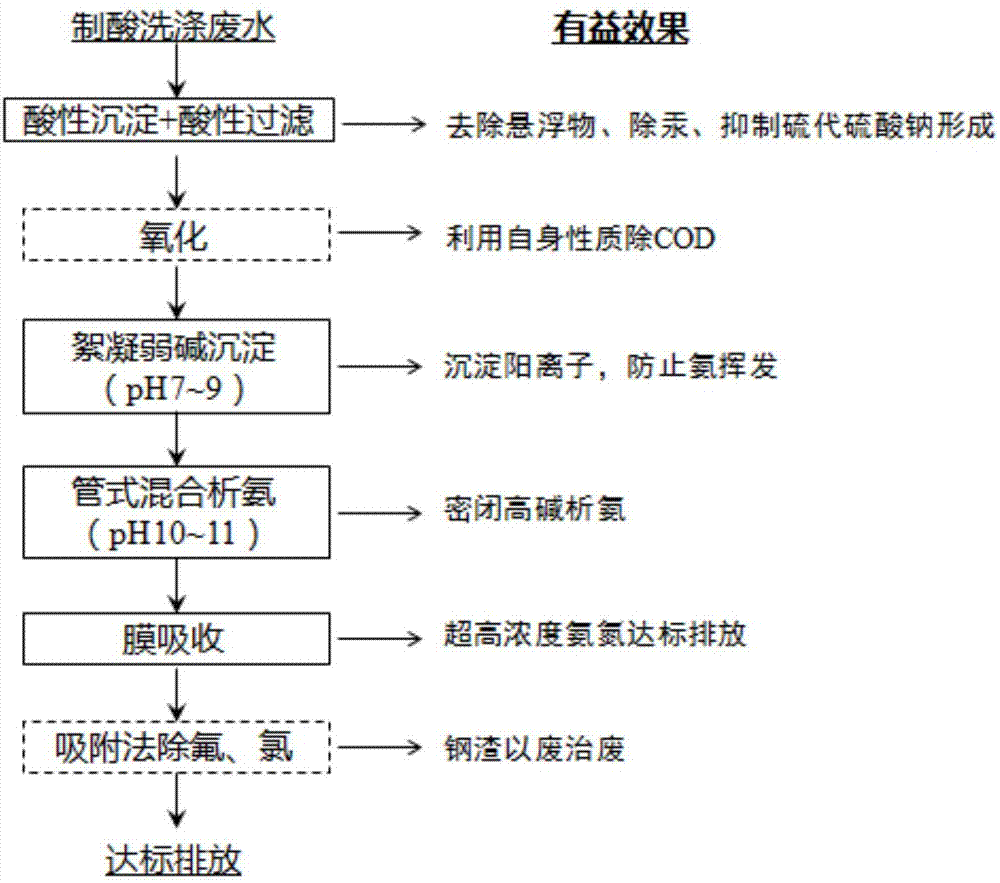

Method used

Image

Examples

Embodiment approach

[0097] According to the second embodiment provided by the present invention, a method for treating acidic flue gas scrubbing wastewater is provided.

[0098] The use of a method for treating acidic flue gas washing wastewater, the method described in the first embodiment is used to treat the acidic flue gas washing wastewater produced by adsorption method adsorbent desorption gas washing. Preferably, the adsorbent comprises solid or liquid. More preferably, the adsorbent is one or more of activated carbon, molecular sieves, MOFs, ionic liquids, and organic amines.

[0099] The following examples are intended to further illustrate the present invention, rather than limit the present invention.

Embodiment 1

[0101] The simulated wastewater is high-suspended-suspended acidic wastewater prepared by carbon powder adsorbed with colloidal sulfur, sulfurous acid, and sulfuric acid. The initial SS concentration is 3000mg / L and pH=0.68.

[0102] 1) Solid-liquid separation:

[0103] Acid precipitation: Add the simulated wastewater into the vertical sedimentation tank, and keep the residence time in the vertical sedimentation tank for 4h. Due to the high density of carbon powder suspended matter, most of it will settle to the bottom of the vertical sedimentation tank and be discharged through the mud pump. The wastewater after passing through the vertical sedimentation tank mainly contains a small amount of small particles of carbon powder, and the SS concentration is 428mg / L;

[0104] Acid filtration: Add the supernatant of the vertical sedimentation tank to an acid-resistant laminated filter with a filter diameter of 1mm; after passing through the acid-resistant laminated filter, the sup...

Embodiment 2

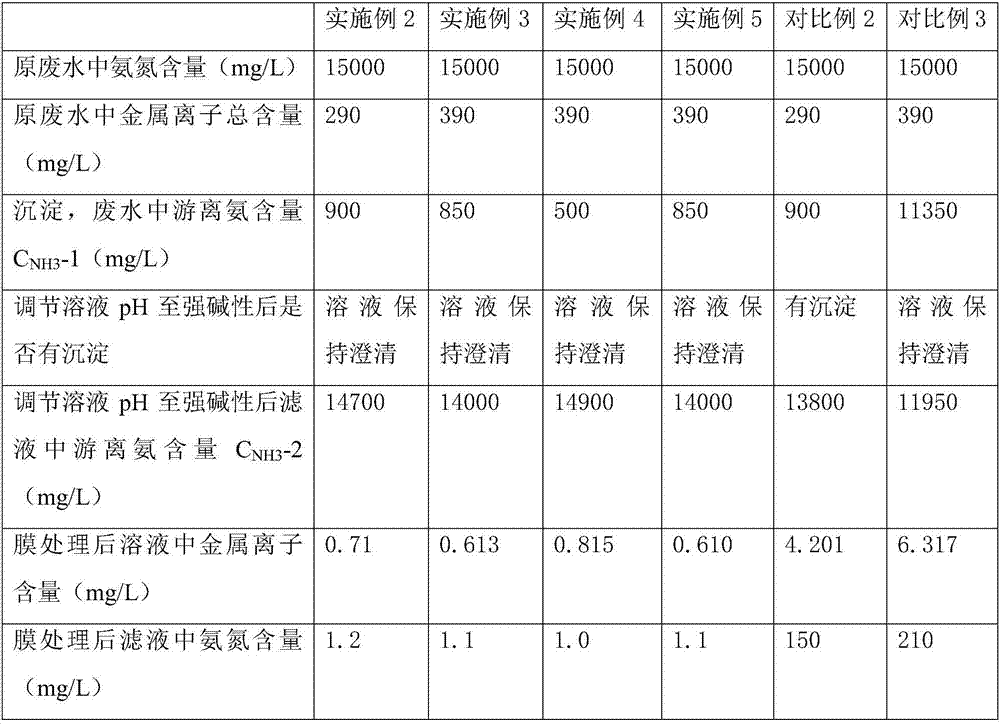

[0110] The simulated wastewater is high-suspended-suspended acidic wastewater prepared by carbon powder adsorbed with colloidal sulfur, sulfurous acid, and sulfuric acid. The initial SS concentration is 3000mg / L and pH=0.68. The total iron in the wastewater is 120mg / L, the total aluminum is 80mg / L, the total calcium is 90mg / L, and the ammonia nitrogen is 15000mg / L.

[0111] 1) adopt the method for solid-liquid separation in embodiment 1 to process;

[0112] 2) Oxidation: Pass the wastewater solution into the oxidation device, so that the organic matter in the wastewater solution undergoes an oxidative degradation reaction, and removes the organic matter in the wastewater;

[0113] 3) The simulated wastewater was prepared by 15% NaOH and 5% Na 2 CO 3 The mixed alkali of composition adjusts the pH of the solution to 8. At this time, it can be observed that a large amount of precipitation can be formed in the solution, and the concentration of free ammonia in the detection solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com