A kind of super weather-resistant PVDF double-layer powder coating and preparation method thereof

A technology of powder coating and super weather resistance, applied in the direction of powder coating, polyester coating, coating, etc., can solve the problems of high process control requirements, lack of substantial experimental basis, lack of equipment, etc., to improve adhesion, overcome Poor dispersibility and coating adhesion, and the effect of solving cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

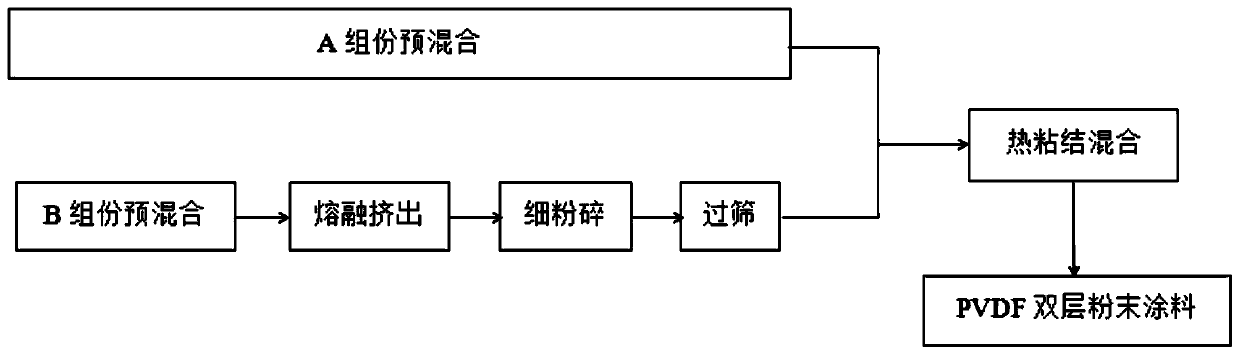

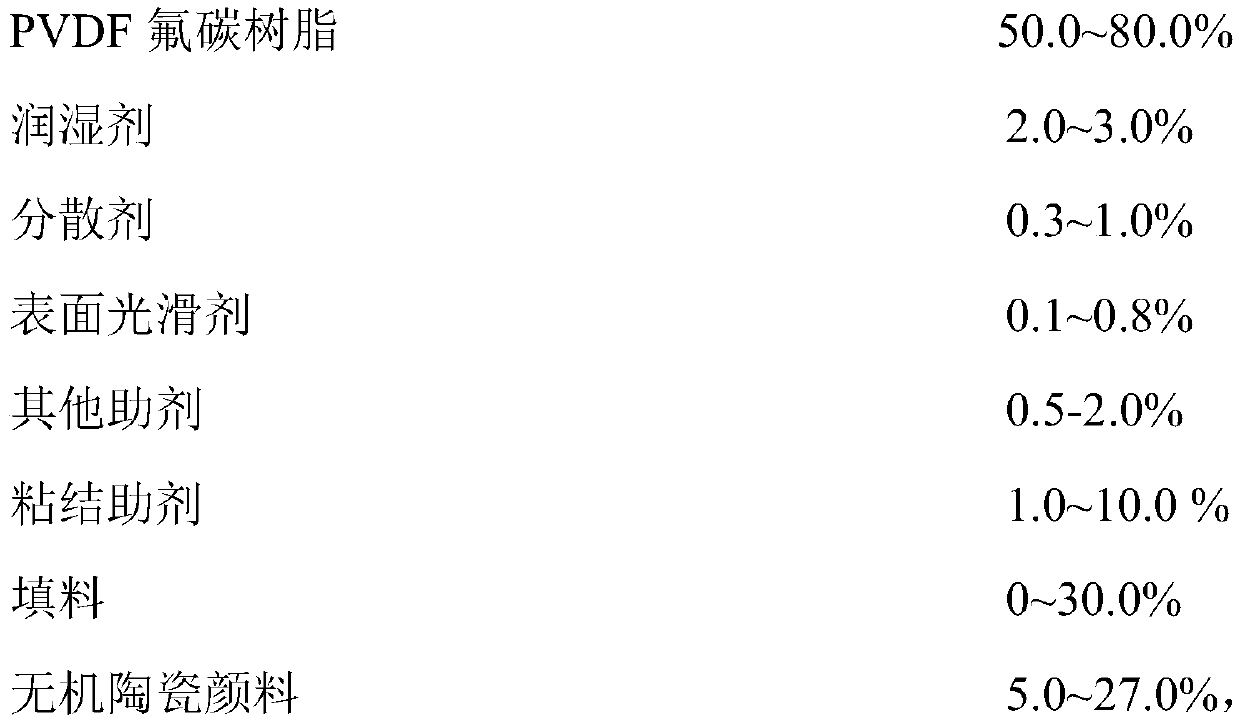

[0059] The curing agent includes one or more of polycarboxylic acid, polybasic acid anhydride, isocyanate, triglycidyl isocyanurate, hydroxyalkylamide, etc., wherein the polycarboxylic acid includes adipic acid, decanedidioic acid acid, dodecanedioic acid, tetradecanedioic acid, octadecanedioic acid; the isocyanate includes blocked trimethylolpropane diisocyanate adduct, blocked isophorone One or more of diisocyanate trimer, hexamethylene diisocyanate adduct, tetramethoxymethyl glycoluril, diketal diisocyanate adduct, caprolactam-blocked isophorone diisocyanate, etc. kind. The preparation method of described PVDF (polyvinylidene fluoride) two-layer powder coating, its flow process is as attached figure 1 shown, including the following steps:

[0060] (1) Pre-mix and melt-mix the raw materials of the above-mentioned component B formula according to their corresponding weight percentages, perform tablet cooling, and finally crush and sieve them into powder particles with a med...

Embodiment 1

[0069] Prepare samples 1-3 of super weather-resistant PVDF double-layer powder coating according to the following steps:

[0070] (1) Premix the following components A and B respectively according to the weight percentage:

[0071]

[0072]

[0073] (2) After pre-mixing the raw materials of the above-mentioned component B, use a twin-screw extruder to melt, knead, disperse and extrude evenly. 145-155℃, extrusion screw frequency 30-50Hz; tableting, coarse crushing;

[0074] (3) The coarsely crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40-55Hz, and the frequency of the auxiliary mill is 25-45Hz, and the finely crushed material is classified into a modified powder coating through a 160-180 mesh standard sieve;

[0075] (4) Pre-mix some of the raw materials in the above component A formula and add them to the reaction kettle. The input sequence of the raw materials and the corresponding operations are as follows: pre-mix PVDF fl...

Embodiment 2

[0107] Prepare super weather-resistant PVDF double-layer powder coating samples 6-8 according to the following steps:

[0108] (1) Premix the following E and F component raw materials respectively according to the weight percentage:

[0109]

[0110]

[0111] (2) After pre-mixing the raw materials of the above-mentioned component F, use a twin-screw extruder to melt, knead, disperse and extrude evenly. 145-155℃, extrusion screw frequency 30-50Hz; tableting, coarse crushing;

[0112] (3) The crushed material is graded and crushed with an ACM mill, the frequency of the main mill is 40-55Hz, and the frequency of the auxiliary mill is 25-45Hz, and the finely crushed material is classified into a modified powder coating through a 160-180 mesh standard sieve;

[0113] (4) Premix the raw materials in the above component E formula and add them into the reactor. After mixing, put it into the reaction kettle, stir evenly and adjust the stirring frequency, the temperature rises t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com