Flame retardant modified asphalt waterproof paint and production method thereof

A technology of modified asphalt and waterproof coatings, which is applied in asphalt coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., and can solve the problems of cumbersome production of water-emulsified asphalt, poor bonding force of polymer body, poor water resistance and aging resistance etc. to achieve the effect of enhancing chemical affinity, good dispersion, improving water resistance and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

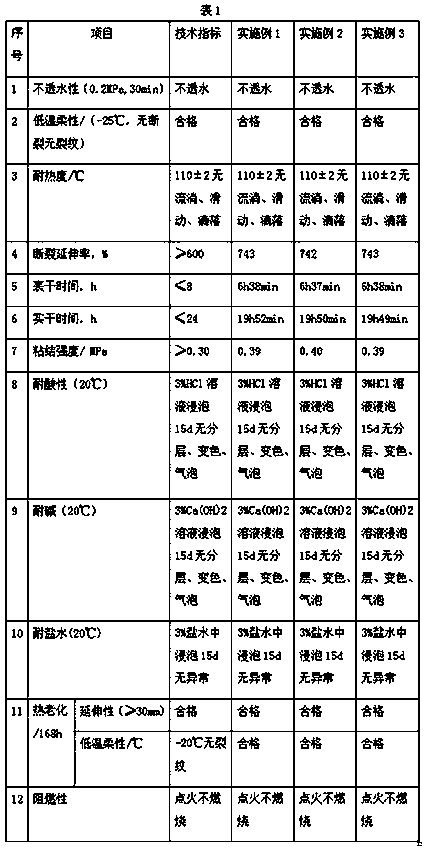

Examples

Embodiment 1

[0027] A fire-retardant modified asphalt waterproof coating, which consists of the following raw materials in parts by weight:

[0028] 50 parts of 90# petroleum asphalt; 60 parts of water; 22 parts of styrene-butadiene latex; 4 parts of emulsifier; 2 parts of polyvinyl alcohol; 2 parts of N-methyl-3-aminopropyltrimethoxysilane; flame retardant microcapsules 3 parts of red phosphorus; 5 parts of polyoxyethylene polyoxypropanolamine ether; 3 parts of triethyl citrate; 0.1 part of hydrogenated rosin glyceride; 1 part of sodium polyacrylate; 10 parts of modified nano-calcium carbonate.

[0029] The emulsifier is obtained by mixing N-alkyltrimethylammonium chloride and polyoxyethylene sorbitan monolaurate in a weight ratio of 8:2.

[0030] The preparation method of the modified nano-calcium carbonate is as follows: dehydrate and dry the nano-calcium carbonate powder at 115° C., then add it to a high-speed mixer, stir and heat up, stop heating at 90° C., and add 2.0% of the mass of...

Embodiment 2

[0036] A fire-retardant modified asphalt waterproof coating, which consists of the following raw materials in parts by weight:

[0037] 62 parts of 90# petroleum asphalt; 66 parts of water; 24 parts of styrene-butadiene latex; 5 parts of emulsifier; 3 parts of polyvinyl alcohol; 4 parts of N-methyl-3-aminopropyltrimethoxysilane; 4 parts of red phosphorus; 6 parts of polyoxyethylene polyoxypropanolamine ether; 4 parts of triethyl citrate; 0.3 parts of hydrogenated rosin glyceride; 2 parts of sodium polyacrylate; 13 parts of modified nano-calcium carbonate.

[0038] The emulsifier is obtained by mixing N-alkyltrimethylammonium chloride and polyoxyethylene sorbitan monolaurate in a weight ratio of 8:2.

[0039] The preparation method of the modified nano-calcium carbonate is as follows: dehydrate and dry the nano-calcium carbonate powder at 117° C., then add it to a high-speed mixer, stir and heat up, stop heating at 90° C., and add chelate powder with a mass of 2.0% of the nano-...

Embodiment 3

[0045] A fire-retardant modified asphalt waterproof coating, which consists of the following raw materials in parts by weight:

[0046] 65 parts of 90# petroleum asphalt; 70 parts of water; 26 parts of styrene-butadiene latex; 6 parts of emulsifier; 4 parts of polyvinyl alcohol; 5 parts of N-methyl-3-aminopropyltrimethoxysilane; flame retardant microcapsules 5 parts of red phosphorus; 7 parts of polyoxyethylene polyoxypropanolamine ether; 5 parts of triethyl citrate; 0.5 parts of hydrogenated rosin glyceride; 3 parts of sodium polyacrylate; 15 parts of modified nano-calcium carbonate.

[0047] The emulsifier is obtained by mixing N-alkyltrimethylammonium chloride and polyoxyethylene sorbitan monolaurate in a weight ratio of 8:2.

[0048] The preparation method of the modified nano-calcium carbonate is as follows: dehydrate and dry the nano-calcium carbonate powder at 120° C., then add it to a high-speed mixer, stir and heat up, stop heating at 90° C., and add 2.0% chelate powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com