Method for improving whiteness of xanthan gum through fermentation condition control and method for detecting xanthan gum fermentation broth

A detection method and technology for fermentation conditions, applied in the field of bioengineering, can solve the problems of cumbersome removal process, high product extraction cost, increased cost of fermentation process treatment, etc., and achieve the effects of good product quality, low extraction cost and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

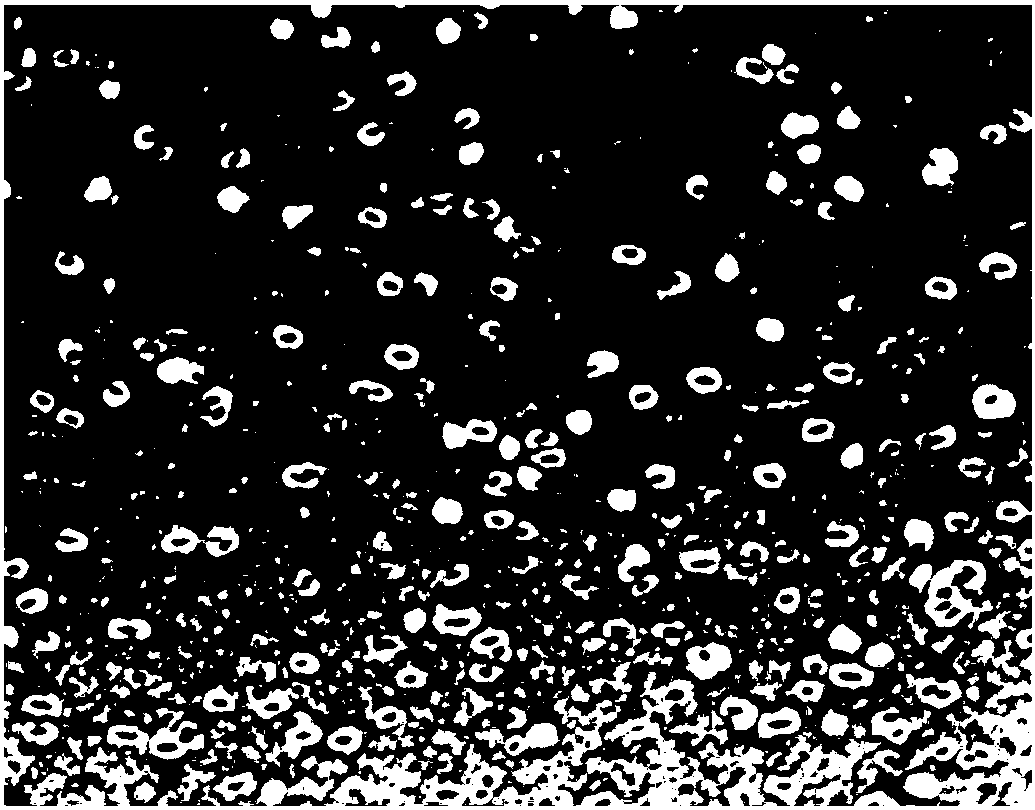

Image

Examples

Embodiment 1

[0019] A method for improving the whiteness of xanthan gum by controlling fermentation conditions, the steps are as follows:

[0020] (1) Slant culture: Xanthomonas campestris (Xanthomonas campestris) 1.1781 cell wall defect strain was streaked and inoculated in the slant medium for cultivation, and the slant medium contained the following components: 20g / L glucose, 1-2g / L yeast powder, 1-2g / L casein peptone, 20g / L agar, culture temperature 30℃, culture time 24-36h;

[0021] (2) Liquid fermentation culture: Take a ring of slant strains and inoculate them in GA-3 liquid fermentation medium, which contains the following components: 35g / L glucose, 0.5-1g / L yeast powder, 0.5-1g / L grain Amino acid, 0.5-1g / L (NH 4 )HPO 4 , 1g / LCaCl 2 , the culture temperature is 30°C, and the culture is 80-100h under aerobic conditions.

[0022] A method for detecting xanthan gum fermentation liquid, using a xanthan gum fermentation liquid obtained by controlling the fermentation condition to i...

Embodiment 2

[0029] A method for improving the whiteness of xanthan gum by controlling fermentation conditions, the steps are as follows:

[0030] (1) Slant culture: Xanthomonas campestris (Xanthomonas campestris) 1.1781 cell wall defect strain was streaked and inoculated in the slant medium for cultivation, and the slant medium contained the following components: 20g / L glucose, 1-2g / L yeast powder, 1-2g / L casein peptone, 20g / L agar, culture temperature 30℃, culture time 24-36h;

[0031] (2) Liquid fermentation culture: Take a ring of slant strains and inoculate them in NF-5 liquid fermentation medium, which contains the following components: 35g / L sucrose, 0.5-1g / L yeast powder, 0.5-1g / L buttermilk Peptone, 0.5-1g / L uracil, 0.5-1g / L (NH 4 )HPO 4 , 1g / L CaCl 2 , 1g / L KH 2 PO 4 , cultivated at 30°C, 200rpm, and cultivated under aerobic conditions for 80-100h.

[0032] A method for detecting xanthan gum fermentation liquid, using a xanthan gum fermentation liquid obtained by controlli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com