Preparation method of high-capacity lithium-rich ternary positive electrode material

A cathode material and high-capacity technology, applied in the field of preparation of high-capacity lithium-rich ternary cathode materials, can solve problems such as difficulty in meeting requirements, and achieve the effects of reducing particle size, increasing specific surface area, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

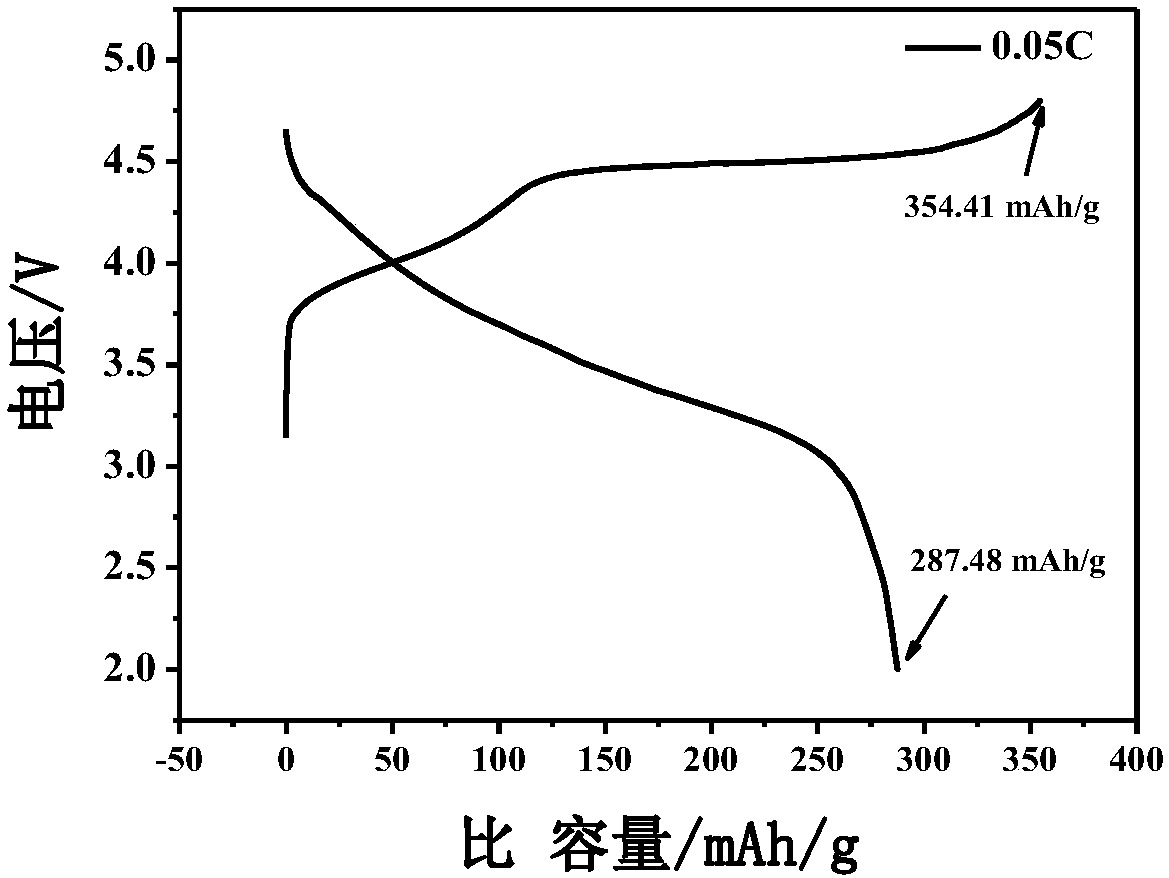

Embodiment 1

[0027] The preparation formula is 0.4Li 2 MnO 3 0.6LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 positive electrode material

[0028] (1) Weigh 29.4108g of manganese acetate tetrahydrate, 9.9536g of nickel acetate tetrahydrate, 9.9632g of cobalt acetate tetrahydrate, and 28.5656g of lithium acetate dihydrate, add 400mL of deionized water, fully stir to dissolve, and obtain a mixed salt solution ;

[0029] (2) Dissolve 21.0140g glucose in 200mL deionized water, stir to dissolve completely;

[0030] (3) Slowly add the glucose solution prepared in step (2) dropwise to the mixed salt solution prepared in step (1), and stir well to make it evenly mixed, then add ammonia water with a concentration of 25wt% to adjust the pH of the solution The value is 8, and the mixed solution system is transferred to a 70°C water bath and kept stirring;

[0031] (4) When the mixed solution in step (3) is in the form of a sol, transfer it to the feed port of the spray dryer for spray drying. The air inlet temp...

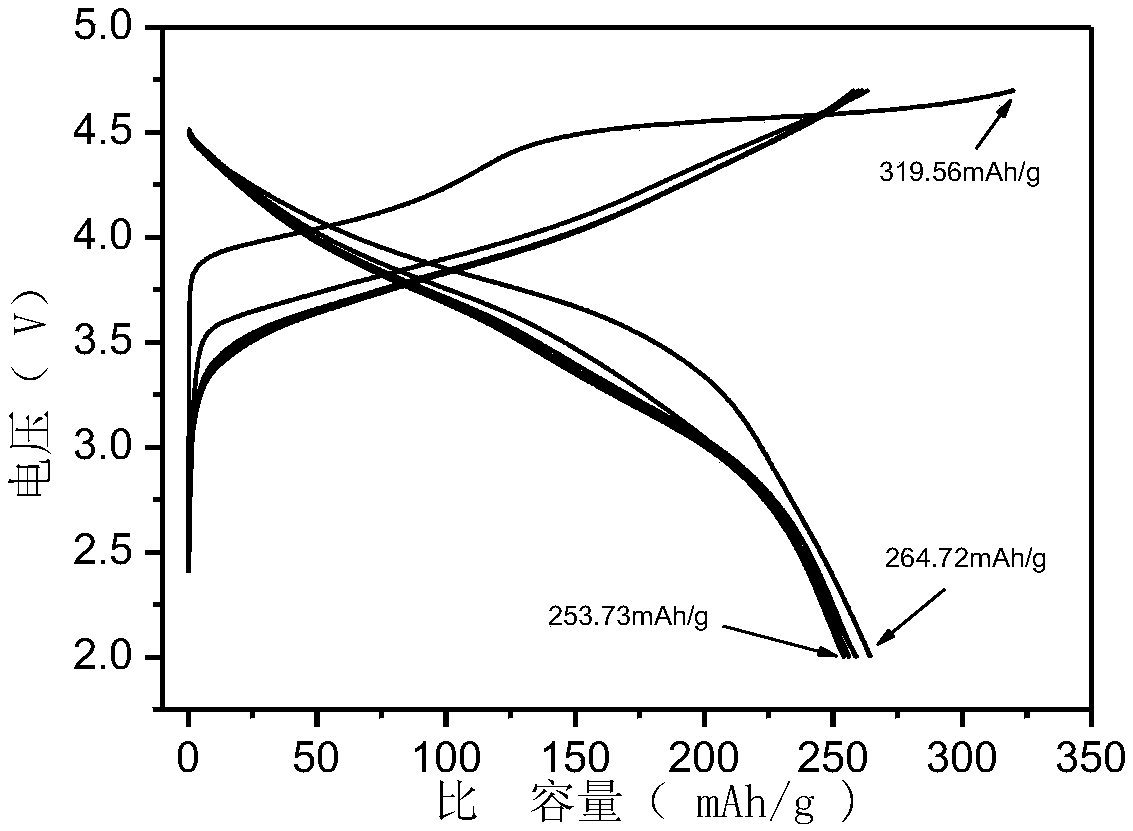

Embodiment 2

[0035] The preparation formula is 0.5Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 positive electrode material

[0036] (1) Weigh 32.5970g of manganese acetate tetrahydrate, 8.2117g of nickel acetate tetrahydrate, 8.2196g of cobalt acetate tetrahydrate, and 30.6060g of lithium acetate dihydrate, respectively, add 400mL of deionized water, stir well to dissolve, and obtain a mixed salt solution ;

[0037] (2) Dissolve 42.028g of citric acid monohydrate in 200mL of deionized water and stir until completely dissolved;

[0038] (3) Slowly add the citric acid solution prepared in the above step (2) dropwise to the mixed salt solution prepared in step (1), and stir well to make it evenly mixed, then add 0.5mol / L sodium hydroxide aqueous solution Adjust the pH value of the solution to 7, and transfer the mixed solution system to a 50°C water bath and keep stirring;

[0039] (4) When the mixed solution in step (3) is in the form of a sol, transfer it to the feed port of the spray d...

Embodiment 3

[0044] The preparation formula is 0.3Li 2 MnO 3 0.7LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 positive electrode material

[0045] (1) Weigh 26.1429g of manganese acetate tetrahydrate, 11.6125g of nickel acetate tetrahydrate, 11.6237g of cobalt acetate tetrahydrate, and 26.5252g of lithium acetate dihydrate, add 400mL of deionized water, stir well to dissolve, and obtain a mixed salt solution ;

[0046] (2) Dissolve 84.0560g sucrose in 400mL deionized water, stir to dissolve completely;

[0047] (3) Slowly add the sucrose solution prepared in the above step (2) dropwise to the mixed salt solution prepared in step (1), and stir well to make it evenly mixed, and add ammonia water with a concentration of 28wt% to adjust the pH of the solution The value is 9, and the mixed solution system is transferred to a 90°C water bath and kept stirring;

[0048] (4) When the mixed solution in step (3) is in the form of a sol, transfer it to the feed port of the spray dryer for spray drying. The air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com