Precious metal-modified carbide catalyst for preparation of hydrogen peroxide, and preparation and application thereof

A carbide and catalyst technology, which is applied in the field of noble metal modified carbide catalysts for preparing hydrogen peroxide, can solve the problems of limited application of carbide catalysts, easy oxidation and deactivation of carbide catalysts, etc., and achieves large market application value and synthesis method. Ease of operation and the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

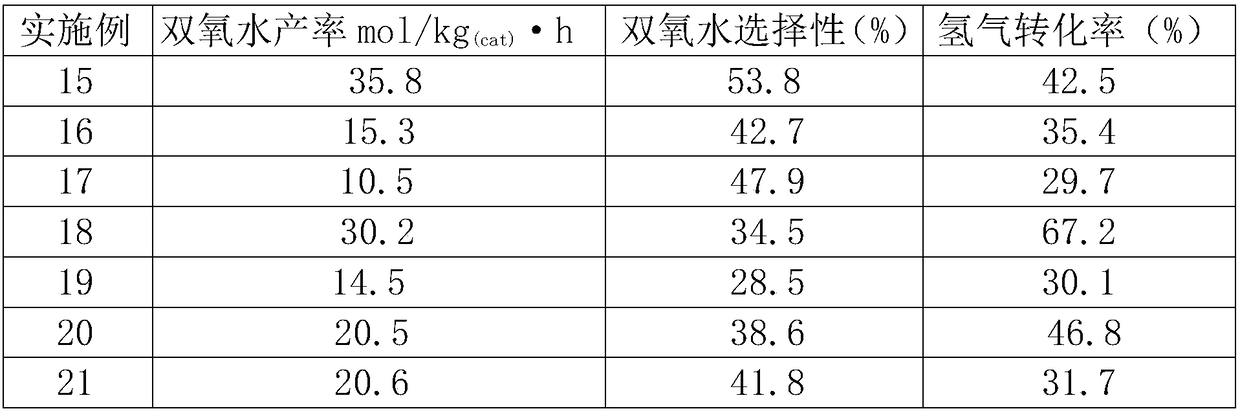

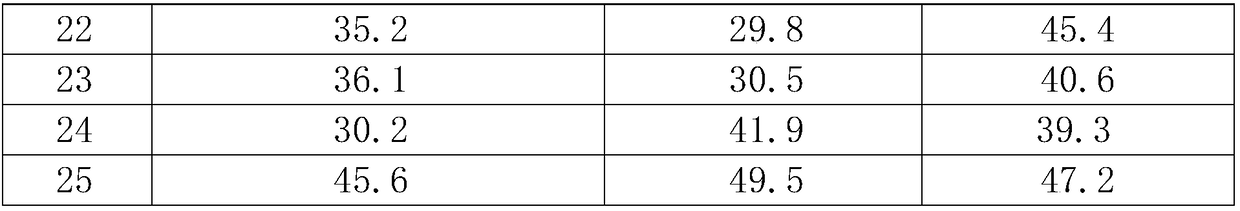

Examples

Embodiment 1

[0029] (1) Preparation of 5% Pd / Mo 2 For samples of C, weigh Pd(NO 3 ) 2 ·nH 2 O 0.0662g and (NH 4 )6 Mo 7 o 24 4H 2 O 1.039g were dissolved in deionized water to form a solution.

[0030] (2) Mix the above solutions with each other, stir at 80°C for 2-3h, let stand for 2h, then dry at 110°C, and then bake at 550°C for 4h in an air atmosphere to obtain PdMoO x catalyst.

[0031] (3) PdMoO x Press it into 20-40 meshes, weigh the samples required for the reaction and place them in a quartz reactor. 4 -H 2 (CH 4 / H 2 =1:4) in a mixed atmosphere of temperature-programmed carbonization, when the temperature rises from room temperature to 300°C, the heating rate is 5°C / min, and from 300°C to the final carbonization temperature (700°C), the heating rate is 1°C / min, At the final carbonization temperature, keep the temperature constant for 120 minutes, drop to room temperature in an argon atmosphere, and use 1% O 2 / Ar passivation for 12h, finally get 5%Pd / Mo 2 C catalys...

Embodiment 2

[0033] Experiments were carried out in a similar manner to Example 1, but the temperature of the reaction during the preparation of the precursor was adjusted to 50°C to obtain the product 5%Pd / Mo 2 C-PdMoO-50 catalyst.

Embodiment 3

[0035] The method similar to Example 1 is used for experiments, but the heating rate in the carbonization process is changed to 5°C / min, and the product 5%Pd / Mo can be obtained 2 C-5 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com