Biological environment-friendly frosted wooden coating and preparation method

A bio-environmental and frosted technology, applied in the field of coatings, can solve the problems of varnish pollution, weak three-dimensional effect, and single color, and achieve the effect of comfortable and natural hand feeling, improved compatibility, and tight integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

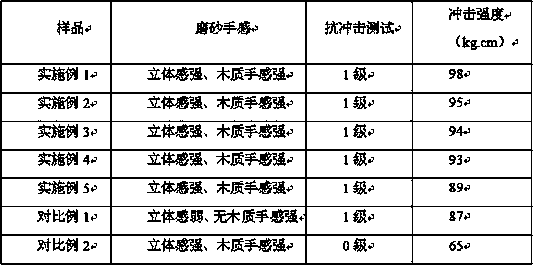

Examples

Embodiment 1

[0027] A bio-environmental frosted wood coating, made of the following parts by weight: 80 parts by weight of water-based polyurethane, 25 parts by weight of coconut shells, 25 parts by weight of peanut shells, 8 parts by weight of α-sulfomonocarboxylate, fourteen 8 parts by weight of alkyl lutidine ammonium bromide, 5 parts by weight of sodium dihydrogen phosphate, 8 parts by weight of shellac, 10 parts by weight of glass microspheres, 6 parts by weight of heptadecafluorodecyl triethoxysilane, ethylene dihydrogen phosphate 3 parts by weight of alcohol siloxane, 5 parts by weight of methylcellulose, 2 parts by weight of n-octylisothiazolinone, and 120 parts by weight of water.

[0028] A kind of preparation method of described bio-environmental protection matte wood paint, comprises the following steps:

[0029] (1) Grind coconut shells and peanut shells into powder, then pass through a 50-mesh sieve to obtain shell powder, soak the shell powder in acidic hydrogen peroxide for...

Embodiment 2

[0033] A bio-environmental protection matte wood coating, made of the following substances by weight: 90 parts by weight of water-based polyurethane, 28 parts by weight of coconut shells, 20 parts by weight of peanut shells, 10 parts by weight of alkylnaphthalene sulfonate, tetradecyl 10 parts by weight of lutidinium bromide, 3 parts by weight of sodium dihydrogen phosphate, 10 parts by weight of shellac, 8 parts by weight of titanium dioxide, 10 parts by weight of trifluorodecyl trichlorosilane, 5 parts by weight of polydimethylsiloxane parts by weight, 6 parts by weight of methylcellulose, 3 parts by weight of n-octylisothiazolinone, and 150 parts by weight of water.

[0034] A kind of preparation method of described bio-environmental protection matte wood paint, comprises the following steps:

[0035] (1) Grind coconut shells and peanut shells into powder, then pass through a 50-mesh sieve to obtain shell powder, soak the shell powder in acidic hydrogen peroxide for 3~5 hou...

Embodiment 3

[0039] A bio-environmental frosted wood coating, made of the following parts by weight: 70 parts by weight of water-based polyurethane, 20 parts by weight of macadamia nut shells, 28 parts by weight of melon seed shells, 5 parts by weight of alkylsulfonate, lauryl 5 parts by weight of dimethylphenoxyethylammonium bromide, 8 parts by weight of sodium dihydrogen phosphate, 6 parts by weight of shellac, 12 parts by weight of titanium dioxide, 5 parts by weight of n-decyltriethoxysilane, ethylene glycol siloxane 2 parts by weight of alkanes, 3 parts by weight of hydroxyethyl cellulose, 1 part by weight of n-octylisothiazolinone, and 180 parts by weight of water.

[0040] A kind of preparation method of described bio-environmental protection matte wood paint, comprises the following steps:

[0041] (1) Grinding the macadamia husk and melon seed husk into powder, passing through a 50-mesh sieve to obtain the husk powder, soaking the husk powder in acidic hydrogen peroxide for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com