Special cleaning agent for flexible printed circuit board as well as preparation method and application of special cleaning agent

A technology for flexible circuit boards and cleaning agents, applied in cleaning methods, preparation of detergent mixture compositions, surface active detergent compositions, etc., can solve the impact on human health, affect the service life of circuit boards, and damage the metal of circuit boards and other problems, to achieve the effect of stability without delamination, improved cleaning ability, and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

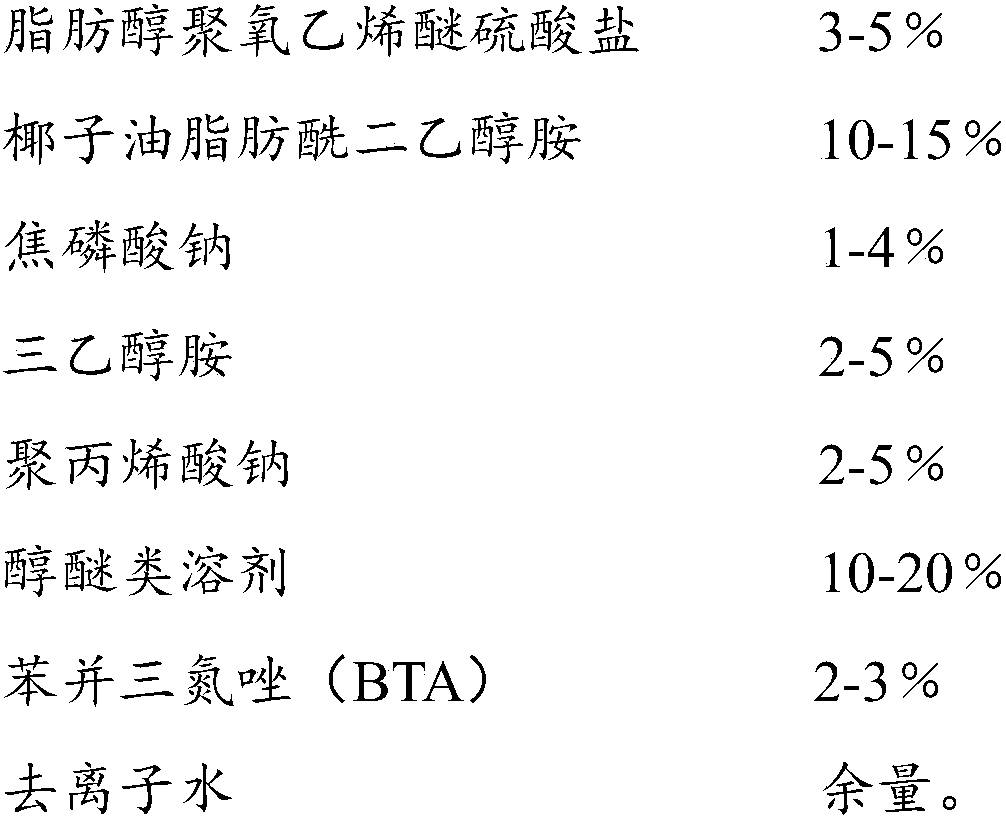

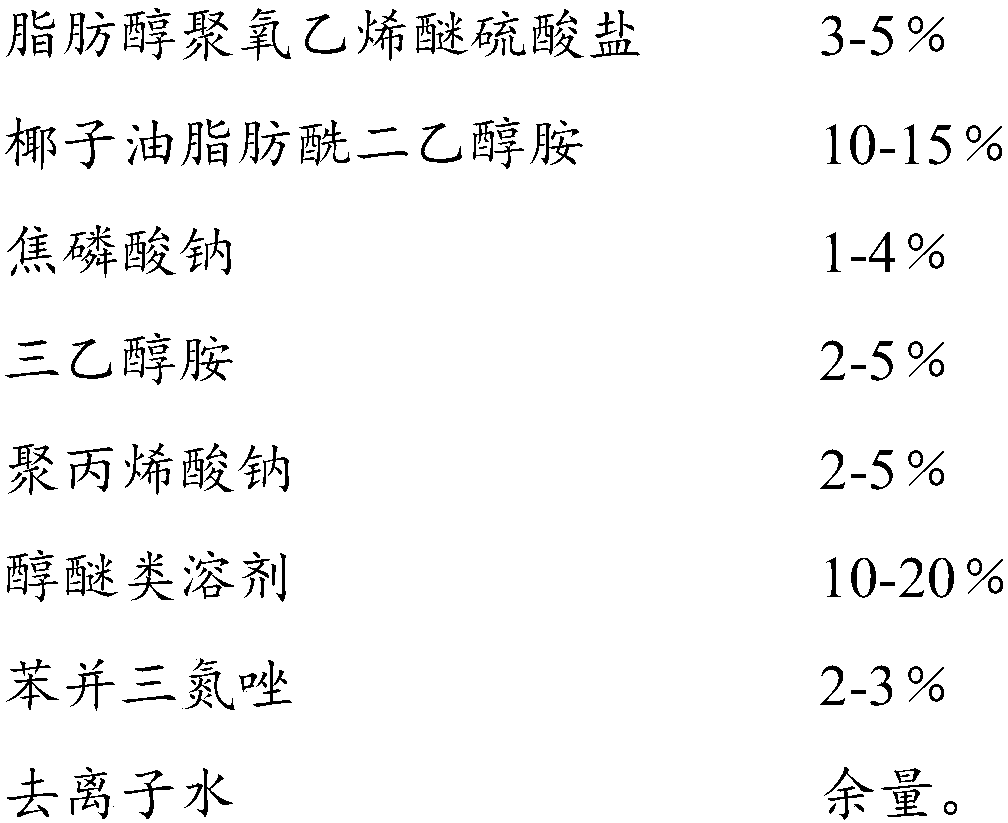

Method used

Image

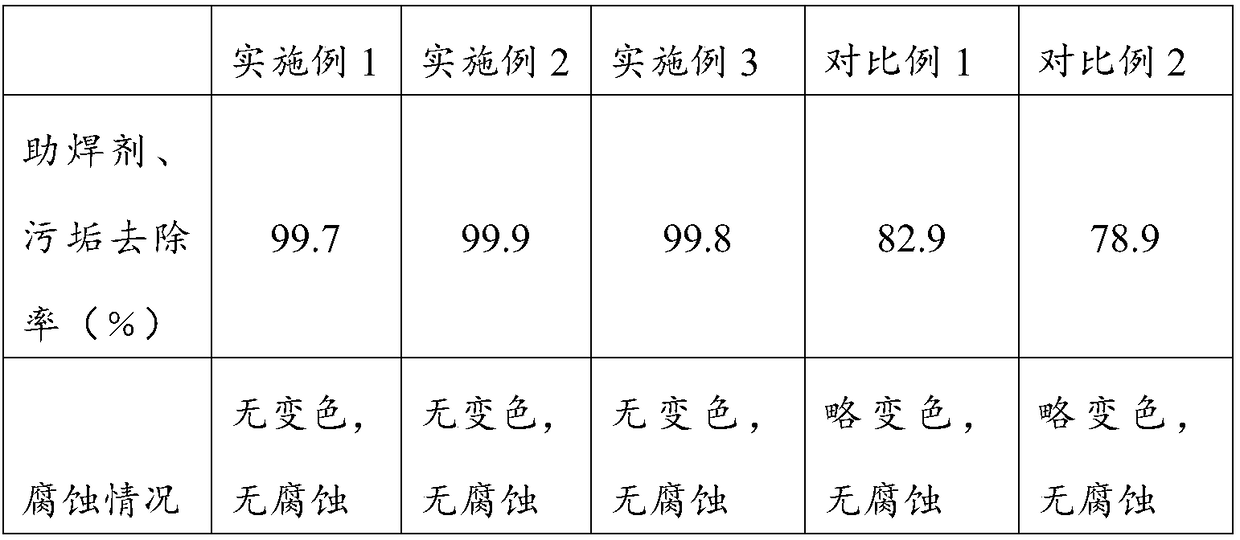

Examples

Embodiment example 1

[0020] A special cleaning agent for flexible circuit boards, including: 3% fatty alcohol polyoxyethylene ether sulfate, 12% coconut oil fatty acyldiethanolamine, 2% sodium pyrophosphate, 3% triethanolamine, and sodium polyacrylate 3%, ethanol 10%, n-butanol 8%, benzotriazole 3%, deionized water balance.

[0021] The preparation method step of this cleaning agent is as follows:

[0022] 1) taking each raw material by weight for subsequent use;

[0023] 2) Mix deionized water, sodium pyrophosphate, sodium polyacrylate, and benzotriazole into a blender, and stir for 10 minutes at normal temperature and pressure;

[0024] 3) Pour fatty alcohol polyoxyethylene ether sulfate, coconut oil fatty acid acyl diethanolamine, triethanolamine, ethanol, and n-butanol into the mixing tank, and continue stirring for 20 minutes to obtain the product.

Embodiment example 2

[0026] A cleaning agent for flexible circuit boards, prepared from the following raw materials in weight percentage: 5% fatty alcohol polyoxyethylene ether sulfate, 10% coconut oil fatty acyldiethanolamine, 3% sodium pyrophosphate, 5% triethanolamine, poly Sodium acrylate 2%, polyethylene glycol 10%, propylene glycol butyl ether 10%, benzotriazole 2%, deionized water balance.

[0027] The preparation method step of this cleaning agent is as follows:

[0028] 1) taking each raw material by weight for subsequent use;

[0029] 2) Mix deionized water, sodium pyrophosphate, sodium polyacrylate, and benzotriazole into a blender, and stir for 15 minutes at normal temperature and pressure;

[0030] 3) Pour fatty alcohol polyoxyethylene ether sulfate, coconut oil fatty acyl diethanolamine, triethanolamine, polyethylene glycol, and propylene glycol butyl ether into the mixing tank, and continue stirring for 15 minutes to obtain the product.

Embodiment example 3

[0032] A cleaning agent for flexible circuit boards, prepared from the following raw materials in weight percentage: 4% fatty alcohol polyoxyethylene ether sulfate, 15% coconut oil fatty acyldiethanolamine, 2% sodium pyrophosphate, 4% triethanolamine, poly Sodium acrylate 4%, ethylene glycol methyl ether 8%, isopropanol 10%, benzotriazole 3%, deionized water balance.

[0033] The preparation method step of this cleaning agent is as follows:

[0034] 1) taking each raw material by weight for subsequent use;

[0035] 2) Mix deionized water, sodium pyrophosphate, sodium polyacrylate, and benzotriazole into a blender, and stir for 20 minutes at normal temperature and pressure;

[0036] 3) Continue to pour fatty alcohol polyoxyethylene ether sulfate, coconut oil fatty acid acyl diethanolamine, triethanolamine, ethylene glycol methyl ether, and isopropanol into the mixing tank, and continue stirring for 10 minutes to obtain the product.

[0037] How to use: Dilute the flexible cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com