Treatment and utilization method for oxytetracycline bacterial residues

A technology of oxytetracycline and fungus residues, which is applied in the preparation methods of peptides, chemical instruments and methods, organic fertilizers, etc., can solve the problems of refractory utilization and difficult release of macromolecular organic matter, and achieves reduction of oxytetracycline residues, Toxic reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

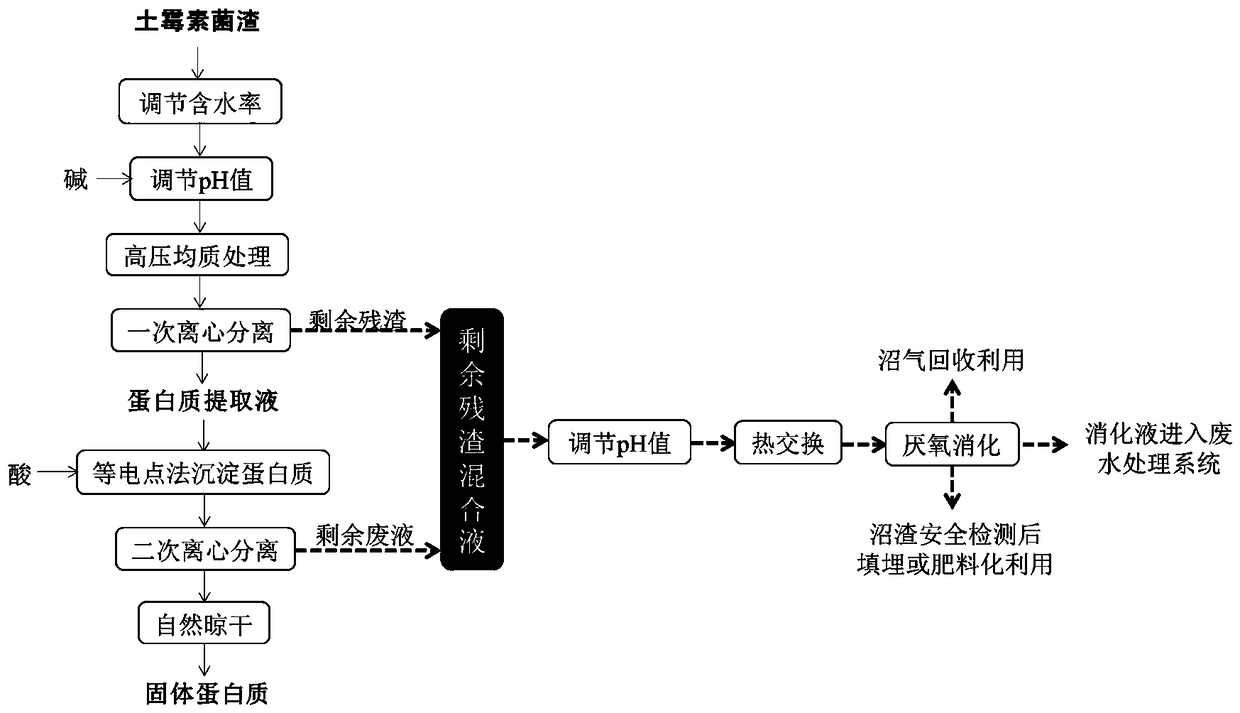

[0039] like figure 1 shown.

[0040] The first step is to adjust the moisture content of the bacteria residue to 95-99%.

[0041] In the second step, alkali is added to adjust the pH of the bacteria residue solution to 11-13.5.

[0042] In the third step, the bacteria residues used in the test are sent to the high-pressure wall breaking machine for processing, and the parameters of the wall breaking are controlled at a pressure of 50-100 MPa and the number of times of wall breaking is 1-5 times; Under the double synergistic effect, the cells were broken and lysed, so that the intracellular substances were released and cracked, the soluble protein content and SCOD concentration in the bacteria residue solution were greatly increased, and the SS concentration in the bacteria residue solution was greatly reduced.

[0043] The fourth step is to centrifuge the broken bacterial residue solution. The centrifugation conditions are controlled at a speed of 3500r / min to 4500r / min and ...

Embodiment 2

[0049] Synergistic pretreatment of oxytetracycline slag by alkali / high pressure wall breaking. Orthogonal experiment design and steps:

[0050] (1) Orthogonal test design: four factors were considered as moisture content of bacteria residue, reaction pH, wall breaking pressure and number of wall breaking, each factor controlled three levels, and L9 (4 3 ) Orthogonal experiment, the experimental design is shown in Table 1.

[0051] (2) Orthogonal test procedure: Weigh a certain amount of oxytetracycline bacteria residue into a beaker, add distilled water to adjust the moisture content of the bacteria residue to a certain moisture content, stir well, and adjust the pH value of the bacteria residue solution through 4 mol / L NaOH solution , and then pour the bacteria residue into the high-pressure wall breaking machine for high-pressure wall breaking treatment. After the high-pressure wall breaking was completed, the mixture of bacteria residue was centrifuged at 3800 r / min for 1...

Embodiment 3

[0056] Single factor level experiment (with protein dissolution rate as the main reference index).

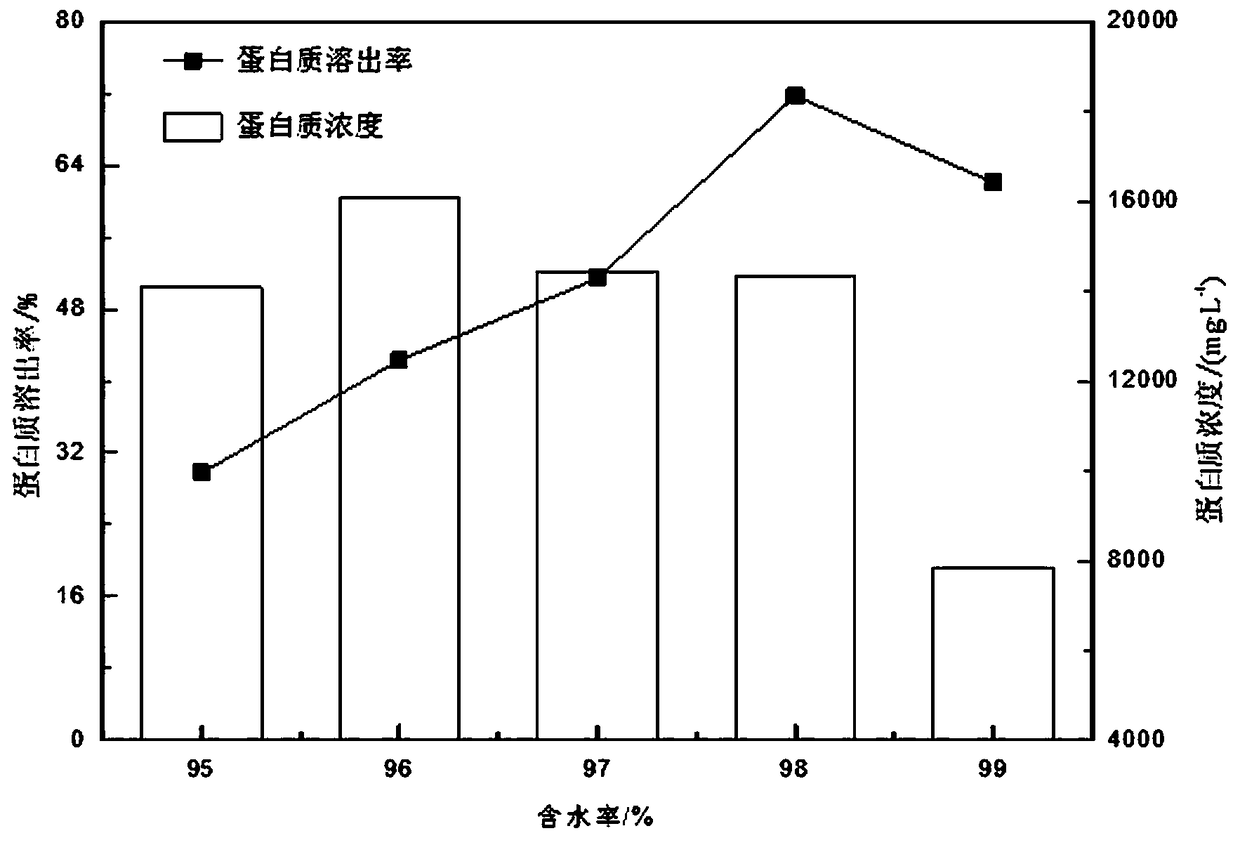

[0057] (1) Effect of water content on protein dissolution rate in oxytetracycline residue

[0058] The selected water content is 95%, 96%, 97%, 98% and 99%, and the other conditions are: pH=13, the number of wall breaking times is 1, and the wall breaking pressure is 70MPa. Test results such as figure 2 . The results showed that the change of water content had a significant effect on the dissolution rate of protein in the bacteria residue. When the water content is lower than 98%, the protein dissolution effect tends to increase. When the water content exceeds 98%, the protein dissolution efficiency decreases instead, which shows that the dissolved concentration of protein in oxytetracycline slag can reach saturation under the test conditions.

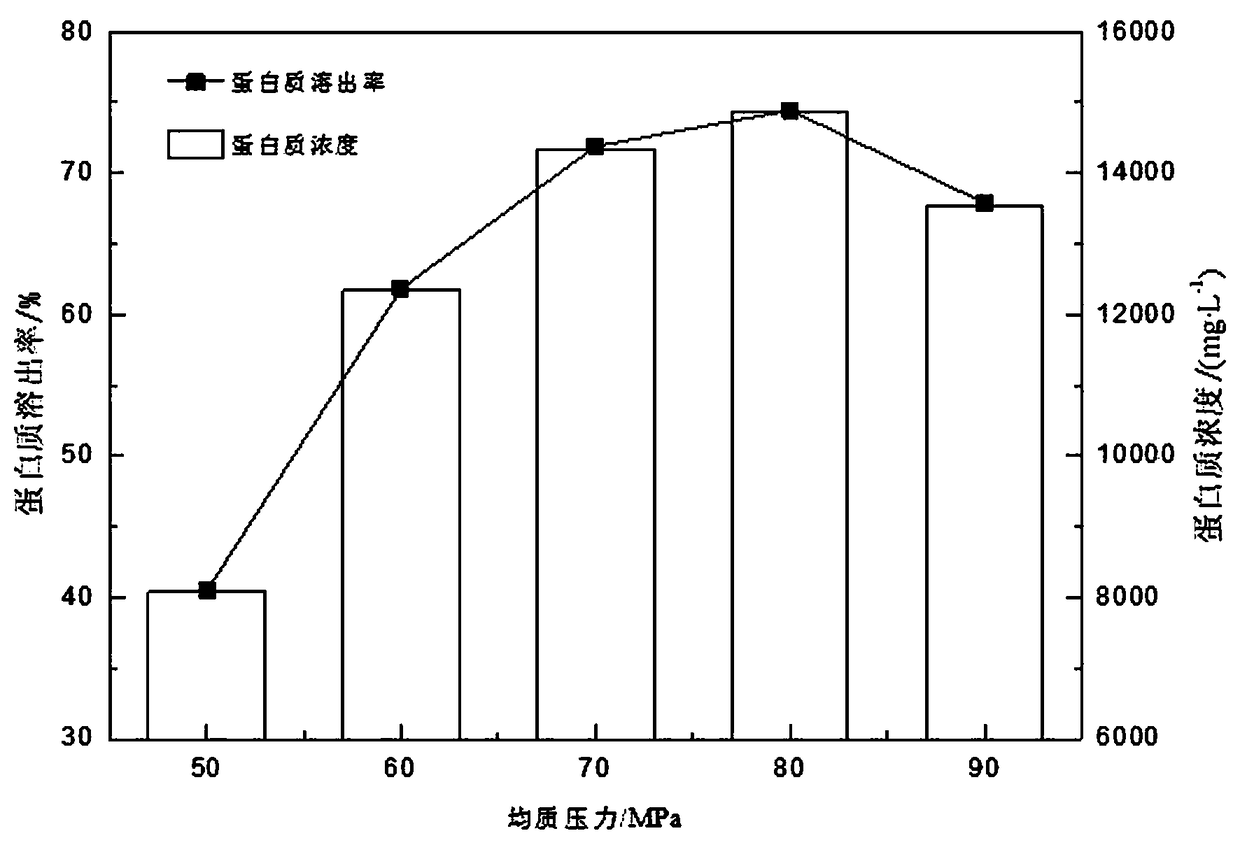

[0059] (2) Effect of wall-breaking pressure on protein dissolution rate from oxytetracycline residue

[0060] The wall-breaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com