Insulating rubber tape and preparation method thereof

An insulating tape and rubber technology, applied in the direction of adhesives, polyether adhesives, film/sheet-like adhesives, etc. The effect of reducing dielectric loss, increasing dielectric constant and breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

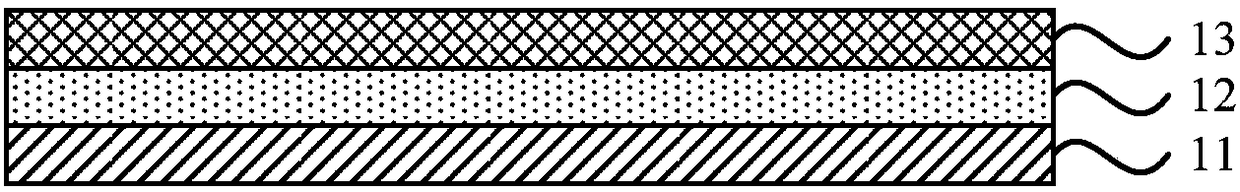

[0066] An insulating tape, comprising a substrate 11, a first dielectric layer 12 and a second dielectric layer 13 stacked in sequence;

[0067] Wherein, base material 11 is kraft paper;

[0068] The first dielectric layer 12 is composed of the following components in parts by mass: 200 parts of styrene-butadiene rubber SBR1502, 18 parts of carbon powder, 15 parts of hydrogenated rosin resin, 15 parts of γ-chloropropyl trimethoxysilane and 15 parts of butyl octyl Diphenylamine, the thickness of which is 0.3mm;

[0069] The second dielectric layer 13 is composed of the following components by mass: 140 parts of butyl rubber IIR1751, 90 parts of barium titanate, 15 parts of hydrogenated rosin resin, 15 parts of vinyltrimethoxysilane and 15 parts of bis-octyldi Aniline, its thickness is 0.5mm.

[0070] The preparation method of above-mentioned insulation tape is as follows:

[0071] (1) Put the components of the first dielectric layer 12 into the internal mixer, melt and knead a...

Embodiment 2

[0076] An insulating tape, comprising a substrate 11, a first dielectric layer 12 and a second dielectric layer 13 stacked in sequence;

[0077] Wherein, base material 11 is PE (polyethylene) film;

[0078] The first dielectric layer 12 is composed of the following components in parts by mass: 200 parts of butyl rubber IIR1751, 16 parts of acetylene black, 15 parts of aromatic petroleum resin (C9), 15 parts of γ-mercaptopropyltriethoxysilane and 15 parts of alkylated N-phenyl-α-naphthylamine having a thickness of 0.3 mm;

[0079] The second dielectric layer 13 is composed of the following components in parts by mass: 140 parts of styrene-butadiene rubber, 90 parts of strontium barium titanate, 15 parts of aromatic petroleum resin (C9), 12 parts of γ-mercaptopropyltriethoxy Silane and 15 parts of alkylated N-phenyl-α-naphthylamine to a thickness of 0.5 mm.

[0080] The preparation method of above-mentioned insulation tape is as follows:

[0081] (1) Put the components of the...

Embodiment 3

[0086] An insulating tape, comprising a substrate 11, a first dielectric layer 12 and a second dielectric layer 13 stacked in sequence;

[0087] Wherein, base material 11 is PVC (polyvinyl chloride) film;

[0088] The first dielectric layer 12 is composed of the following components in parts by mass: 200 parts of nitrile rubber 1051M50, 14 parts of polyaniline, 15 parts of disproportionated rosin resin, 15 parts of anilinomethyltrimethoxysilane and 15 parts of 2,6- Di-tert-butyl-4-methylphenol, the thickness of which is 0.2 mm;

[0089] The second dielectric layer 13 is composed of the following components in parts by mass: 140 parts of butadiene rubber BR9000, 90 parts of lead zirconate titanate, 15 parts of disproportionated rosin resin, 15 parts of anilinomethyltrimethoxysilane and 15 parts of 2, 6-di-tert-butyl-4-methylphenol with a thickness of 0.4 mm.

[0090] The preparation method of above-mentioned insulation tape is as follows:

[0091] (1) Put the components of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com