Aluminum alloy prefabricated branched cable and preparation method thereof

A technology of prefabricating branches and aluminum alloys, which is applied in the direction of insulating cables, cables, circuits, etc., and can solve problems such as inability to apply high temperature environments and insufficient high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

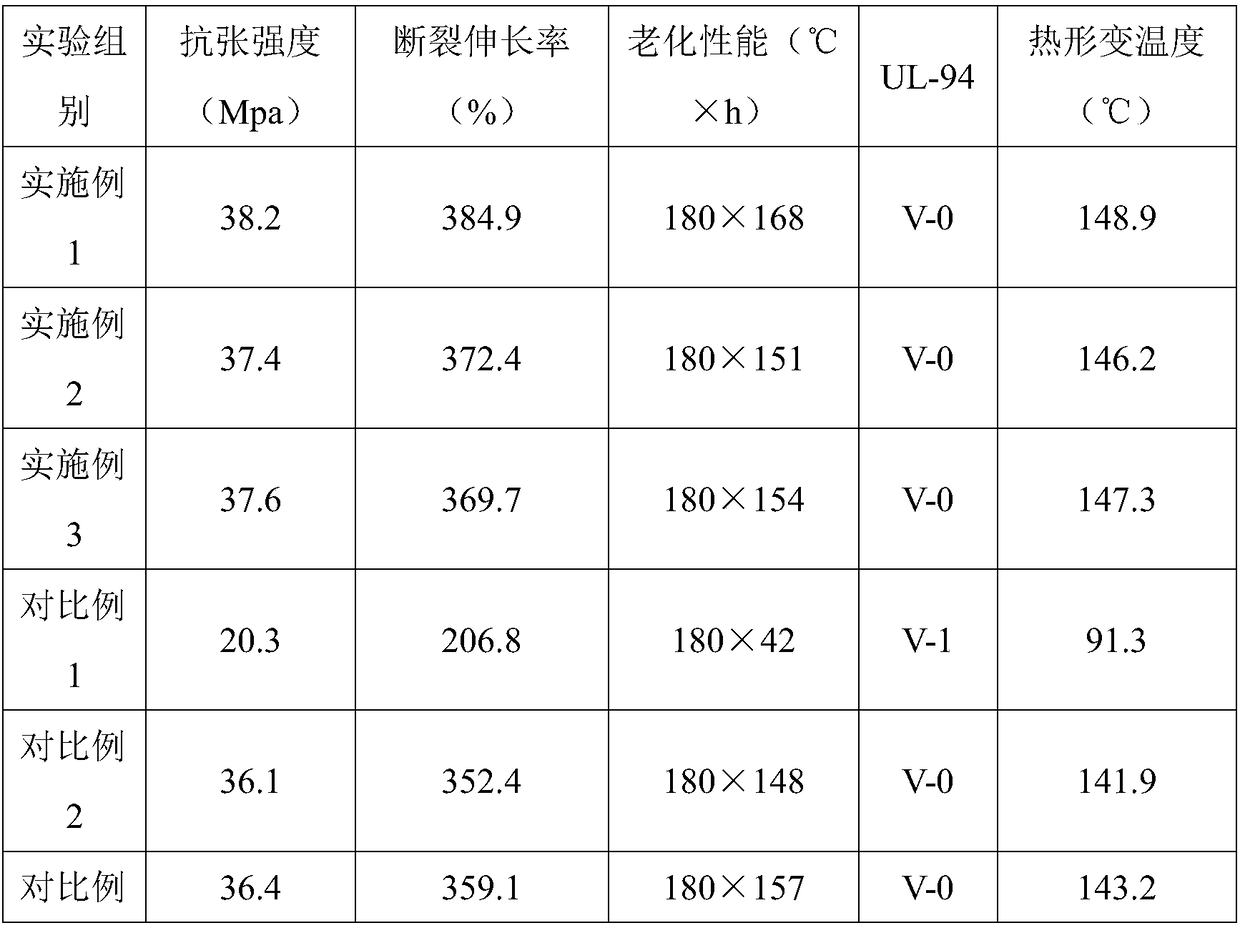

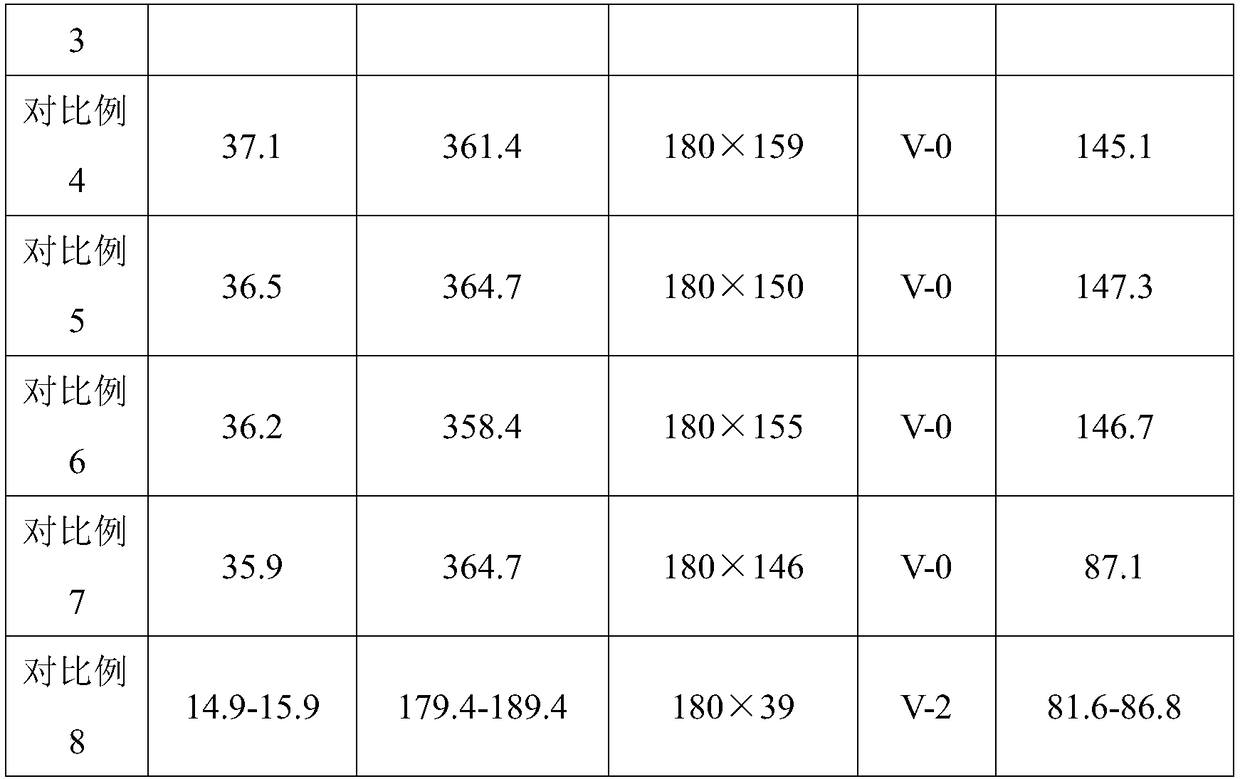

Examples

preparation example Construction

[0025] The preparation method of the aluminum alloy prefabricated branch cable comprises the following steps:

[0026](1) Preparation of cable material: a. Heat up high-density polyethylene and polytetrafluoroethylene to 140-160°C, keep warm for 20-40min, then add polycarbonate, dialkyl phosphoric acid, polyethylene glycol, magnesium carbonate, Mix nano-montmorillonite, calcium nitrate, carbon black, graphite, hydroxyapatite and nano-silicon dioxide evenly, continue to heat up to 180-220°C, keep warm for 5-15min, stir at 3500-5500r / min for 1-2h, Cool to room temperature to obtain base material;

[0027] b. Mix polypropylene and styrene evenly, raise the temperature to 80-120°C, keep it warm for 10-30min, then under the protection of nitrogen, reflux at 110-130°C for 4-8h, then cool to room temperature, add diisopropyl peroxide Mix benzene evenly, wash and dry by rotary evaporation to constant weight, cool to room temperature, then add chloroform and mix evenly, blend at 160-2...

Embodiment 1

[0038] An aluminum alloy prefabricated branch cable, including injection molded as a whole main cable, branch cables and aluminum alloy CL-shaped clamp, the aluminum alloy CL-shaped clamp connects the main cable and branch cables together, and wraps them in turn There is a layer of self-adhesive waterproof tape and two layers of hot-melt adhesive. The main cable includes a main conductor, a main cable insulation layer, a main cable filling core, a main cable wrapping tape and a main cable outer sheath, which are arranged in sequence from the built-in outside. The branch cable includes a branch conductor, a branch cable insulation layer, a branch cable filling core, a branch cable wrapping tape and a branch cable outer sheath arranged in sequence from inside to outside; the main conductor of the main cable and the branch conductor of the branch cable They are all composed of multiple aluminum alloy conductor cores. The main cable insulation layer, main cable outer sheath, branch...

Embodiment 2

[0046] An aluminum alloy prefabricated branch cable, including injection molded as a whole main cable, branch cables and aluminum alloy CL-shaped clamp, the aluminum alloy CL-shaped clamp connects the main cable and branch cables together, and wraps them in turn There is a layer of self-adhesive waterproof tape and two layers of hot-melt adhesive. The main cable includes a main conductor, a main cable insulation layer, a main cable filling core, a main cable wrapping tape and a main cable outer sheath, which are arranged in sequence from the built-in outside. The branch cable includes a branch conductor, a branch cable insulation layer, a branch cable filling core, a branch cable wrapping tape and a branch cable outer sheath arranged in sequence from inside to outside; the main conductor of the main cable and the branch conductor of the branch cable They are all composed of multiple aluminum alloy conductor cores. The main cable insulation layer, main cable outer sheath, branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com