Lithium cell based preparation method of multi-layer metal-carbon navigate electrode

A multi-layer metal and lithium battery technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as weak structural stability, affecting the stability of lithium ion deintercalation channels, and large internal resistance, achieving increased stability performance, improve the effect of high internal resistance and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

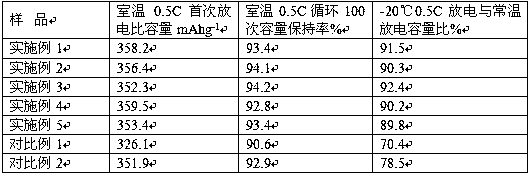

Examples

Embodiment 1

[0028] (1) Immerse the sheet copper foil with a thickness of 80 microns in the acetone solution, set the ultrasonic power to 50kW, and ultrasonic time for 5 minutes, clean and remove the oil stains on the surface, and put the sheet copper foil degreased on the surface into the pH value In the acetic acid solution of 5, the temperature of the acetic acid solution is controlled to be 40°C, and the treatment time is 16 minutes, and the surface oxide layer is corroded by the acetic acid surface to obtain pure copper foil;

[0029] (2) The pure copper foil is grooved on one side by etching process, using hydrogen peroxide and dilute hydrochloric acid with a volume concentration of 15% as the corrosion solution, the corrosion time is 10 minutes, the corrosion depth is 5 microns, and after cleaning with deionized water, A copper foil with raised arrays obtained through nitrogen blowing intervention;

[0030] (3) Using PECVD technology, set the background vacuum of the deposition cham...

Embodiment 2

[0035] (1) Immerse the sheet copper foil with a thickness of 120 microns in the acetone solution, set the ultrasonic power to 30kW, and ultrasonic time for 20 minutes, clean and remove the surface oil stains, and put the sheet copper foil with degreased surface into the pH value In the acetic acid solution of 3, the temperature of the acetic acid solution is controlled at 70°C, and the treatment time is 10 minutes, and the surface oxide layer is corroded by the acetic acid surface to obtain pure copper foil;

[0036] (2) The pure copper foil is grooved on one side by etching process, hydrogen peroxide and dilute hydrochloric acid with a volume concentration of 17% are used as the corrosion solution, the corrosion time is 5 minutes, the corrosion depth is 9 microns, and after cleaning with deionized water, A copper foil with raised arrays obtained through nitrogen blowing intervention;

[0037] (3) Using PECVD technology, set the background vacuum of the deposition chamber to 1...

Embodiment 3

[0042] (1) Immerse the sheet copper foil with a thickness of 100 microns in the acetone solution, set the ultrasonic power to 40kW, and ultrasonic time for 12 minutes, clean and remove the oil stains on the surface, and put the sheet copper foil degreased on the surface into the pH value In the acetic acid solution of 3, the temperature of the acetic acid solution is controlled to be 55°C, and the treatment time is 12 minutes, and the surface oxide layer is corroded by the acetic acid surface to obtain pure copper foil;

[0043] (2) The pure copper foil is grooved on one side by etching process, hydrogen peroxide and dilute hydrochloric acid with a volume concentration of 16% are used as the corrosion solution, the corrosion time is 8 minutes, the corrosion depth is 6 microns, and after cleaning with deionized water, A copper foil with raised arrays obtained through nitrogen blowing intervention;

[0044] (3) Using PECVD technology, set the background vacuum degree of the depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com