Preparation method of chlorosulfonated polyether-ether-ketone composite material film

A technology of composite film and chlorosulfonated polyether, which is applied in the field of polyether ether ketone materials, can solve the requirements of an energy system that cannot meet the requirements of efficient, clean, economical and safe energy systems, dimensional stability, and the decline in mechanical strength and alcohol resistance , Reaction catalyst poisonous cathode performance decline and other problems, to achieve the effect of improving water absorption and water retention capacity, good anti-protonic acid corrosion performance, and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

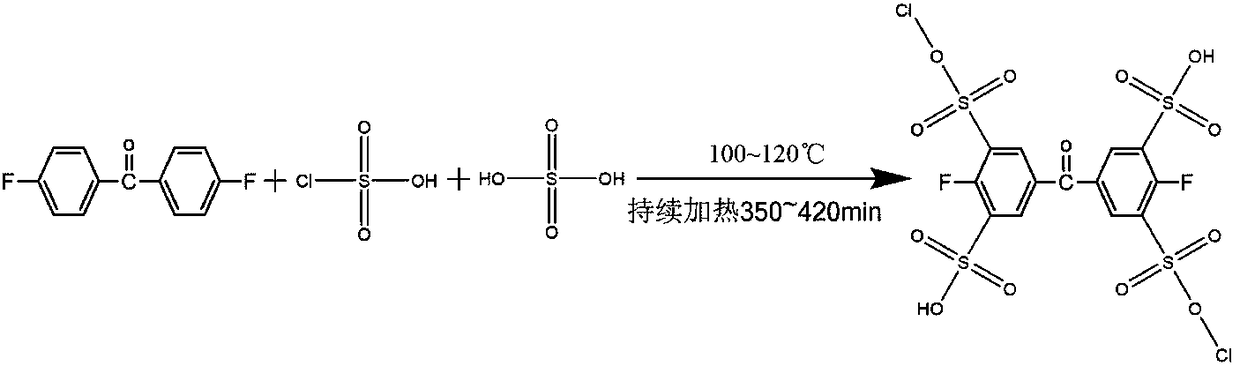

[0038] 1. Synthesis of chlorosulfonated fluoroketones

[0039]Put 20 parts of 4,4-difluorobenzophenone, 15 parts of chlorosulfonic acid, and 65 parts of oleum into a three-necked flask equipped with a mechanical stirring device, a thermometer and a coil condenser, and continuously stir at 2°C / Min heating rate, heating to 110°C, continuous insulation reaction for 360min, cooling down to 40°C, and putting the mixture into ice water for cooling, using potassium hydroxide solution to neutralize the solution to neutral, using sodium chloride Salt out, filter to obtain solid crude product, recrystallize with ethanol and water, and finally obtain chlorosulfonated fluoroketone;

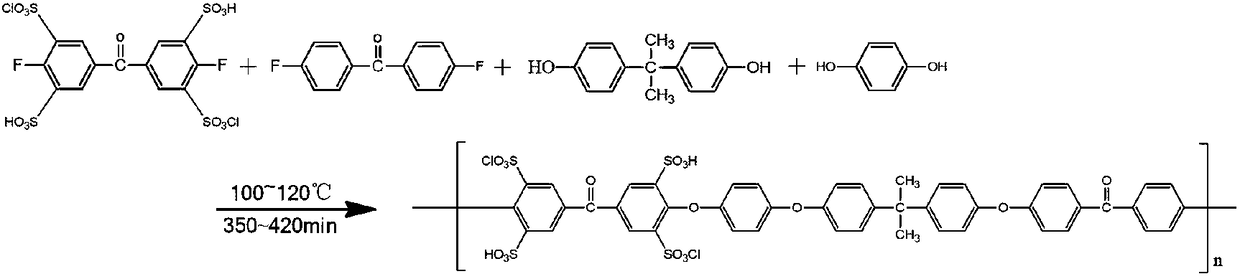

[0040] 2. Synthesis of chlorosulfonated polyetheretherketone

[0041] In a three-necked flask equipped with a stirrer, a thermometer, and a coil condenser, add 3 parts of 4,4-difluorobenzophenone, 5 parts of chlorosulfonated fluoroketone, 3 parts of potassium carbonate, 1 part of sodium carbonate, 5 parts ...

Embodiment 2

[0045] 1. Synthesis of chlorosulfonated fluoroketones

[0046] Put 25 parts of 4,4-difluorobenzophenone, 15 parts of chlorosulfonic acid, and 60 parts of oleum into a three-necked flask equipped with a mechanical stirring device, a thermometer and a coil condenser, and continuously stir at 2°C / Min heating rate, heating to 110°C, continuous insulation reaction for 390min, then cooling down to 50°C, and putting the mixture into ice water for cooling, using potassium hydroxide solution to neutralize the solution to neutral, using sodium chloride for Salt out, filter to obtain solid crude product, recrystallize with ethanol and water, and finally obtain chlorosulfonated fluoroketone;

[0047] 2. Synthesis of chlorosulfonated polyetheretherketone

[0048] In a three-neck flask equipped with a stirrer, a thermometer, and a coil condenser, add 4 parts of 4,4-difluorobenzophenone, 7 parts of chlorosulfonated fluoroketone, 4 parts of potassium carbonate, 2 parts of sodium carbonate, ...

Embodiment 3

[0052] 1. Synthesis of chlorosulfonated fluoroketones

[0053] Put 30 parts of 4,4-difluorobenzophenone, 20 parts of chlorosulfonic acid, and 50 parts of oleum into a three-necked flask equipped with a mechanical stirring device, a thermometer and a coil condenser, and continuously stir at 4 ° C / Min heating rate, heating to 110°C, continuous insulation reaction for 420min, then cooling down to 40°C, and putting the mixture into ice water for cooling, using potassium hydroxide solution to neutralize the solution to neutral, using sodium chloride Salt out, filter to obtain solid crude product, recrystallize with ethanol and water, and finally obtain chlorosulfonated fluoroketone;

[0054] 2. Synthesis of chlorosulfonated polyetheretherketone

[0055] In a three-necked flask equipped with a stirrer, a thermometer, and a coil condenser, add 5 parts of 4,4-difluorobenzophenone, 8 parts of chlorosulfonated fluoroketone, 5 parts of potassium carbonate, 2 parts of sodium carbonate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com