Gold-zinc oxide hetero-junction nano-particle array and method for preparing same

A nanoparticle array and nanoparticle technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of weak absorption strength and reduced catalytic reaction efficiency, so as to promote application, high catalytic reaction efficiency, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

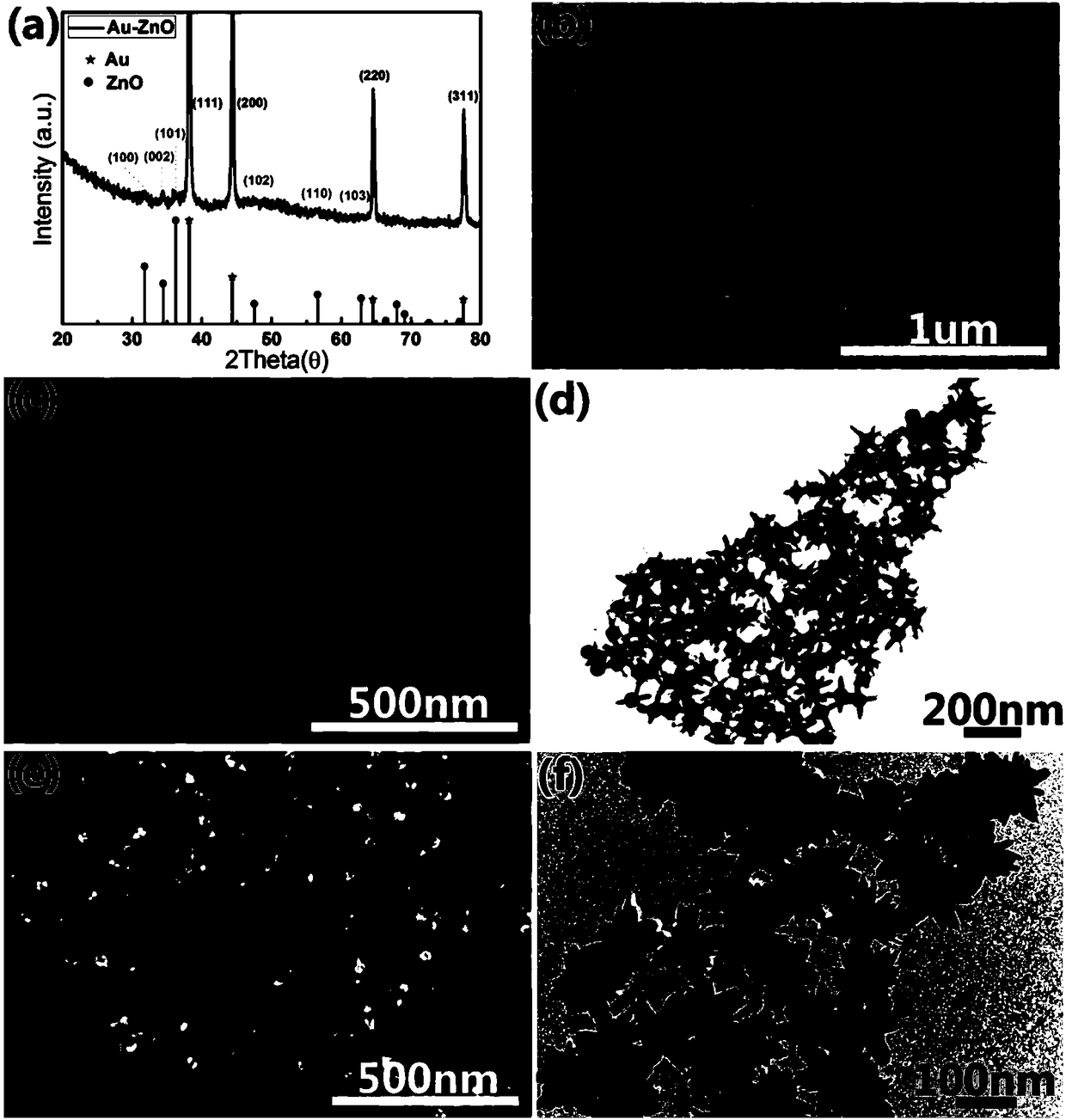

[0029] Specifically, the preparation method of the gold-zinc oxide heterojunction nanoparticle array may include the following steps:

[0030] Step A, mixing gold nanospheres, zinc nitrate, sodium hydroxide, and sodium borohydride in water so that the concentration of gold nanospheres in the mixed solution is 0.2 to 0.3 mmol / L, and the concentration of zinc nitrate is 0.001 to 0.008 mmol / L, the concentration of sodium hydroxide is 15-30 mmol / L, and the concentration of sodium borohydride is 5-20 mmol / L, and the precursor mixed solution is prepared. In practical application, the gold nanospheres are prepared by the following preparation method: adding chloroauric acid, diethylene glycol diacrylate phthalate (PDDA, as a surfactant), and hydrochloric acid to an ethylene glycol solvent , and heated to 195°C in an oil bath, kept for 30 minutes, and then wet-chemically etched with a small amount of hydrochloric acid to obtain a monodisperse colloidal solution of gold nanospheres; t...

Embodiment 1

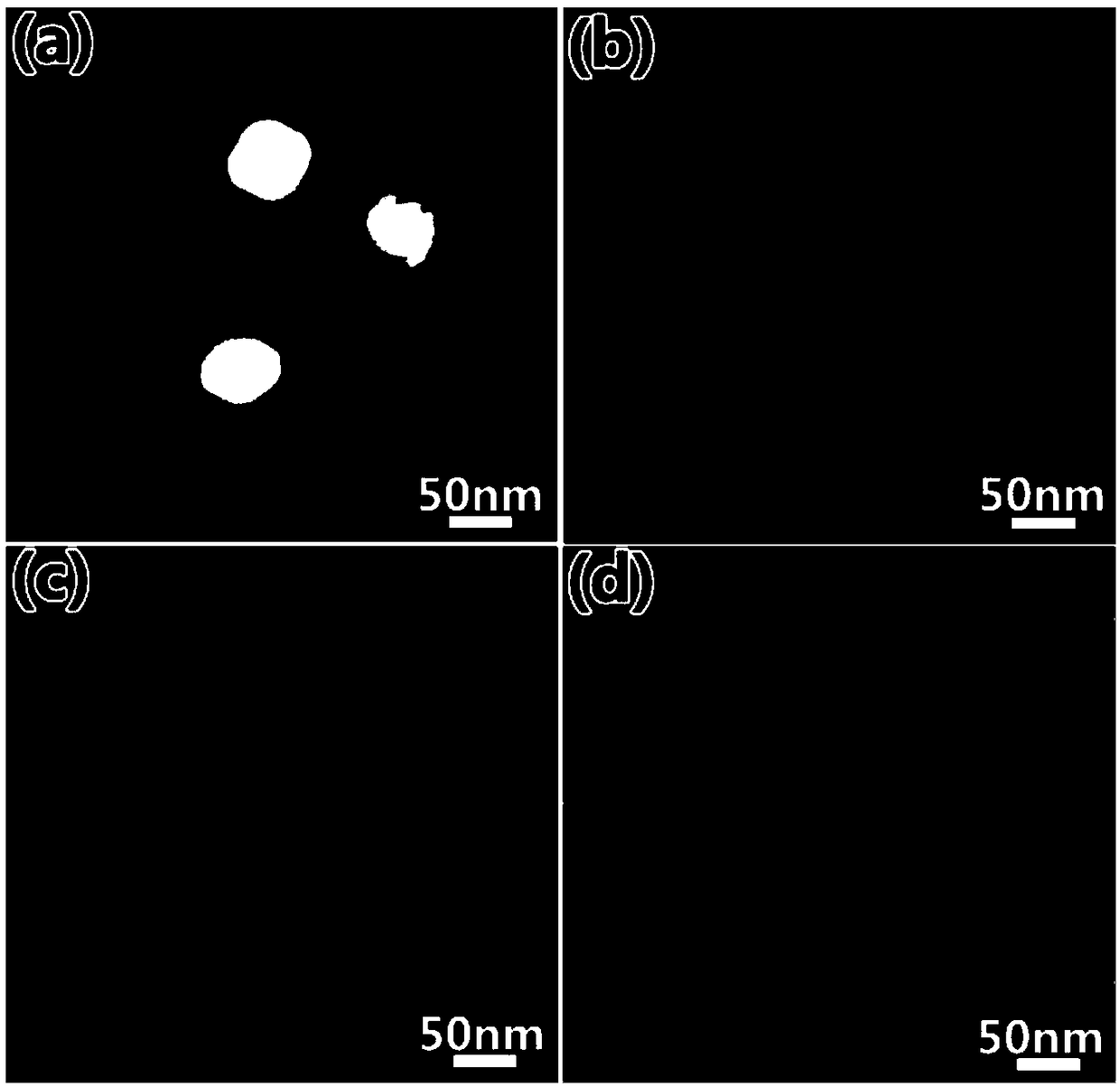

[0042] A gold-zinc oxide heterojunction nanoparticle array, the preparation method of which comprises the following steps:

[0043] Step a1: Add chloroauric acid, diethylene glycol diacrylate phthalate (PDDA, as a surfactant), and hydrochloric acid into ethylene glycol solvent, and heat to 195° C. in an oil bath, and keep the temperature for 30 minutes. Then, a small amount of hydrochloric acid is used for wet chemical etching to obtain a monodisperse gold nanosphere colloidal solution; then, the gold nanosphere colloidal solution is centrifuged to obtain gold nanospheres.

[0044] Step b1: mixing gold nanospheres, zinc nitrate, sodium hydroxide, and sodium borohydride in water so that the concentration of gold nanospheres in the mixed solution is 0.25 mmol / L, the concentration of zinc nitrate is 0.002 mmol / L, hydrogen The concentration of sodium oxide is 30 mmol / L, and the concentration of sodium borohydride is 10 mmol / L to prepare a precursor mixed solution.

[0045] Step c...

Embodiment 2

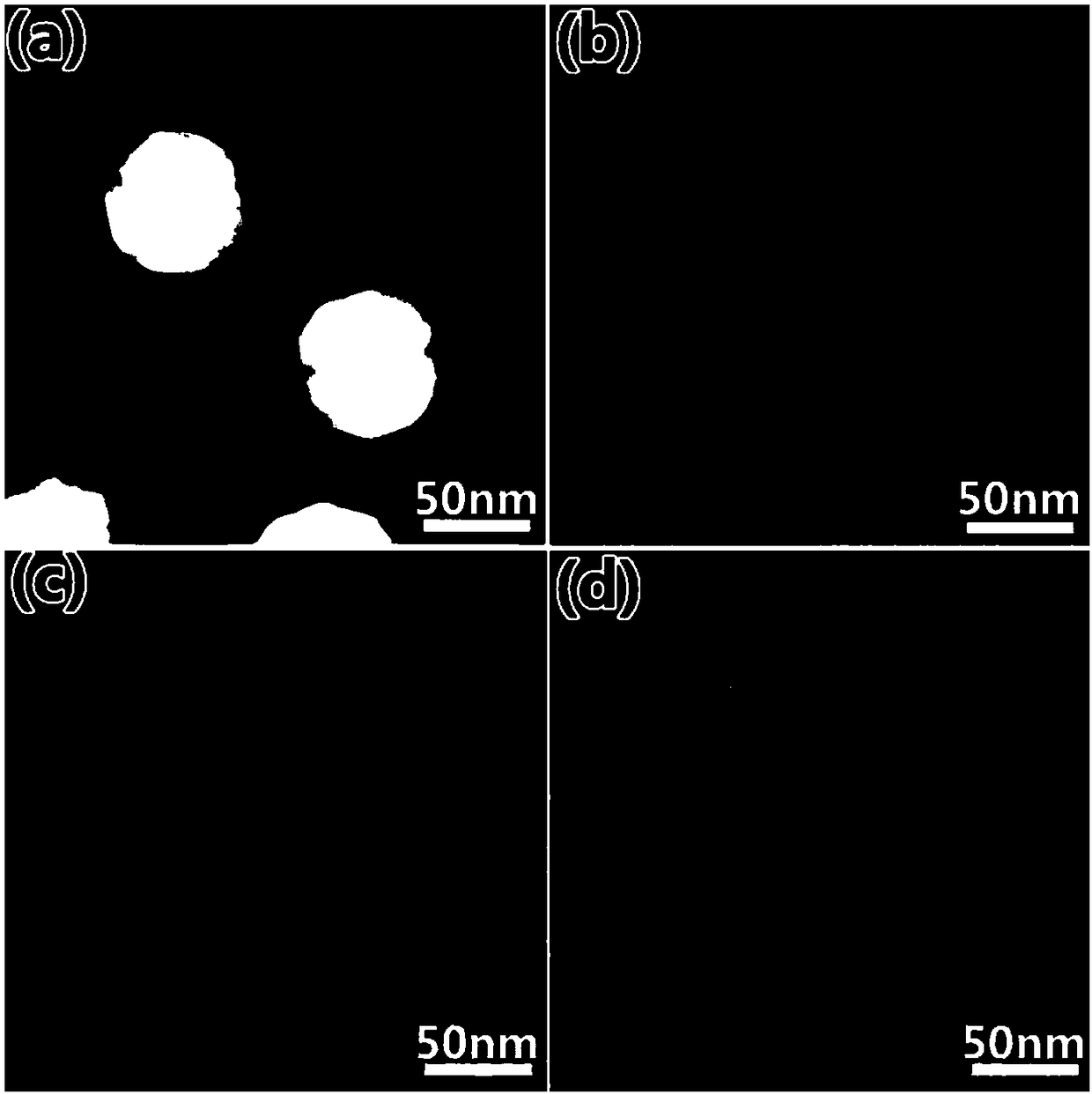

[0049] A gold-zinc oxide heterojunction nanoparticle array, the preparation method of which comprises the following steps:

[0050] Step a2: Add chloroauric acid, diethylene glycol diacrylate phthalate (PDDA, as a surfactant), and hydrochloric acid into the ethylene glycol solvent, and heat it to 195° C. in an oil bath, and keep it warm for 30 minutes. Then, a small amount of hydrochloric acid is used for wet chemical etching to obtain a monodisperse gold nanosphere colloidal solution; then, the gold nanosphere colloidal solution is centrifuged to obtain gold nanospheres.

[0051] Step b2: Mix gold nanospheres, zinc nitrate, sodium hydroxide, and sodium borohydride in water so that the concentration of gold nanospheres in the mixed solution is 0.25 mmol / L, the concentration of zinc nitrate is 0.004 mmol / L, hydrogen The concentration of sodium oxide was 15 mmol / L, and the concentration of sodium borohydride was 10 mmol / L to prepare a precursor mixed solution.

[0052] Step c2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com