Granular manganese dioxide/titanium carbide composite material and preparation method thereof

A technology of manganese dioxide and composite materials, applied in the direction of manganese oxide/manganese hydroxide, titanium carbide, carbide, etc., can solve the problems of inability to control the structure of composite materials, easy agglomeration, and affecting electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention comprises the following steps:

[0025] Step 1, ternary layered Ti 3 AlC 2 Preparation of ceramic powder;

[0026] Synthesize ternary layered Ti according to the method of patent ZL201310497696.9 3 AlC 2 The preparation steps of the ceramic powder specifically include: firstly, mixing the experimental raw materials TiC, Ti, and Al powder according to the molar ratio of TiC:Ti:Al=2.0:1.0:1.2; secondly, mixing the mixture, alumina balls Alumina and absolute ethanol are ball milled in a corundum ball milling tank according to the mass ratio of 1:3:1, in which absolute ethanol is used as a ball milling aid, alumina balls are used as a grinding medium, the speed of the ball mill is 300r / min, and the wet ball milling is 4h Finally, dry in a constant temperature drying oven at 40°C for 24 hours; then, put the dried mixture into a corundum crucible, and carry out vacuum pressureless sintering in a vacuum hot-pressed carbon tub...

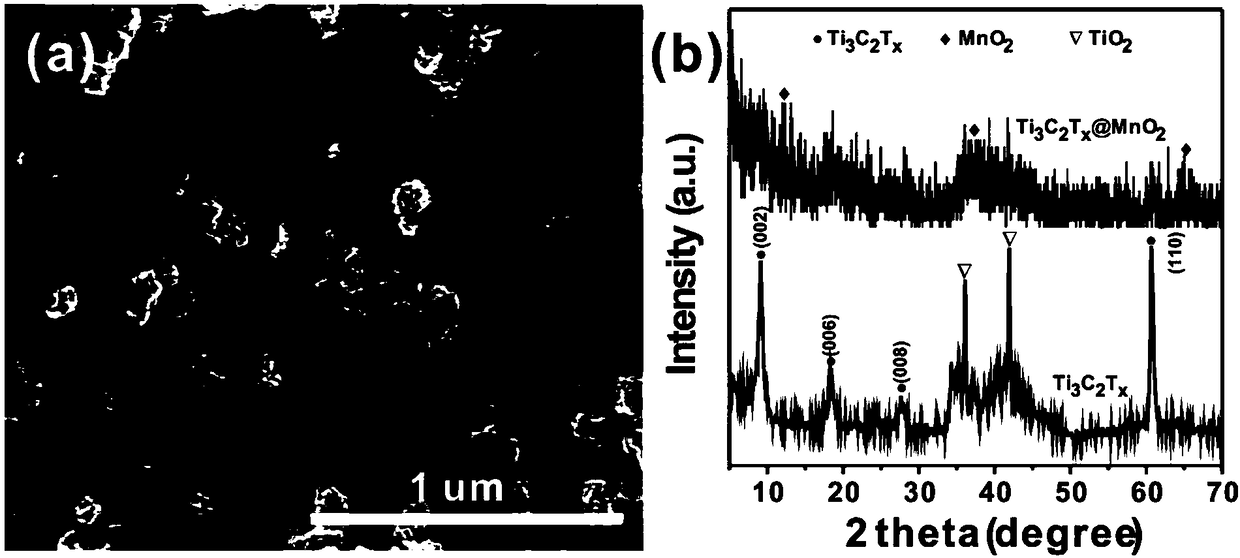

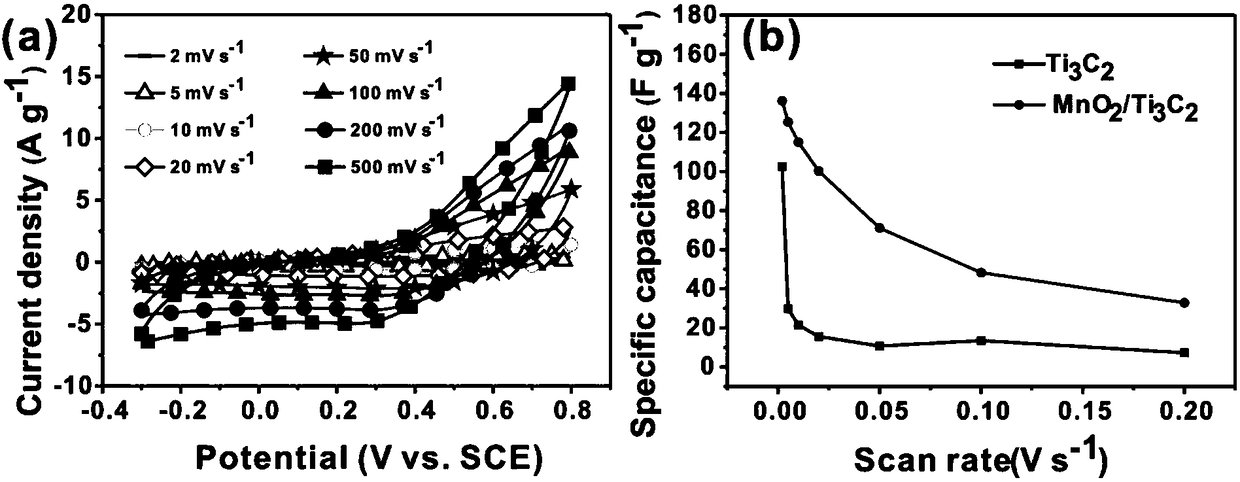

Embodiment 1

[0036] First, prepare 10mL 100mmolL -1 CTAB solution, stirred at room temperature for 30min to completely dissolve CTAB in ultrapure water; 30mg of Ti 3 C 2 Add @PDA nanopowder into CTAB solution, ultrasonically disperse for 30min, and then stir for 1h; after stirring well, add 10mL of 50mmolL -1 KMnO 4 The solution was heated in a water bath at 70° C., stirred and reacted for 3 hours; after the reaction was completed, it was naturally cooled to obtain a rice grain-shaped manganese dioxide / titanium carbide composite material.

Embodiment 2

[0038] First, prepare 10mL 100mmolL -1 CTAB solution, stirred at room temperature for 30min to completely dissolve CTAB in ultrapure water; 30mg of Ti 3 C 2 Add @PDA nanopowder into CTAB solution, ultrasonically disperse for 30min, and then stir for 1h; after stirring well, add 10mL of 100mmolL -1 KMnO 4 The solution was heated in a water bath at 70° C., stirred and reacted for 3 hours; after the reaction was completed, it was naturally cooled to obtain a rice grain-shaped manganese dioxide / titanium carbide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com