Photochromic glass paint and preparation method thereof

A photochromic glass and coating technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of complex process, inability to construct photochromic glass, etc., and achieve good transparency and visible light. The effect of high transmittance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation and detection of photochromic glass coating (1)

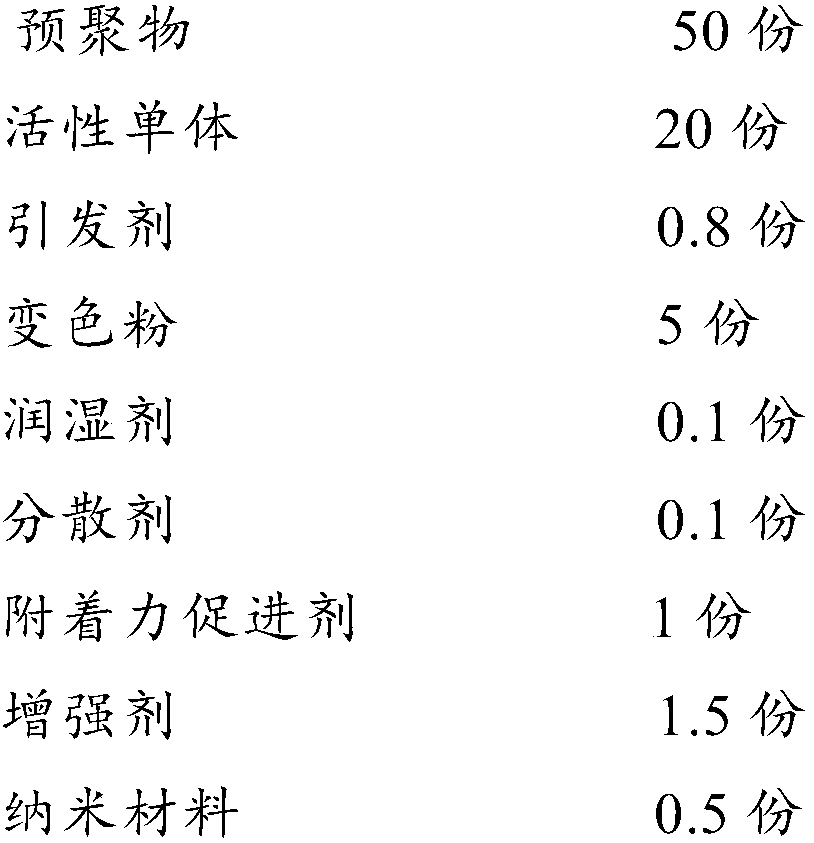

[0030] Prepare the photochromic glass coating with the raw materials in the following weight ratio.

[0031]

[0032] The prepolymer is polyurethane acrylate; the active monomer is tripropylene glycol dipropylene glycol; the initiator is 2-hydroxy-2-methyl-1-phenylacetone; the color changing powder is diarylethene, and the average particle size The diameter is 3 microns; the wetting agent is TEGO-4100; the dispersant is DISPERBYK-110; the adhesion promoter is aminopropyltrimethoxysilane; the strengthening agent is KH570; 10nm.

[0033] The specific preparation process method is as follows.

[0034] (1) First weigh the active monomer, add a wetting agent and a dispersant under stirring, and continue stirring for 30 minutes;

[0035] (2) Add color-changing powder and nanomaterials, and continue to stir and disperse for 30 minutes;

[0036] (3) Add reinforcing agent, initiator, prepolymer, c...

Embodiment 2

[0040] Embodiment 2: Preparation and detection of photochromic glass coating (two)

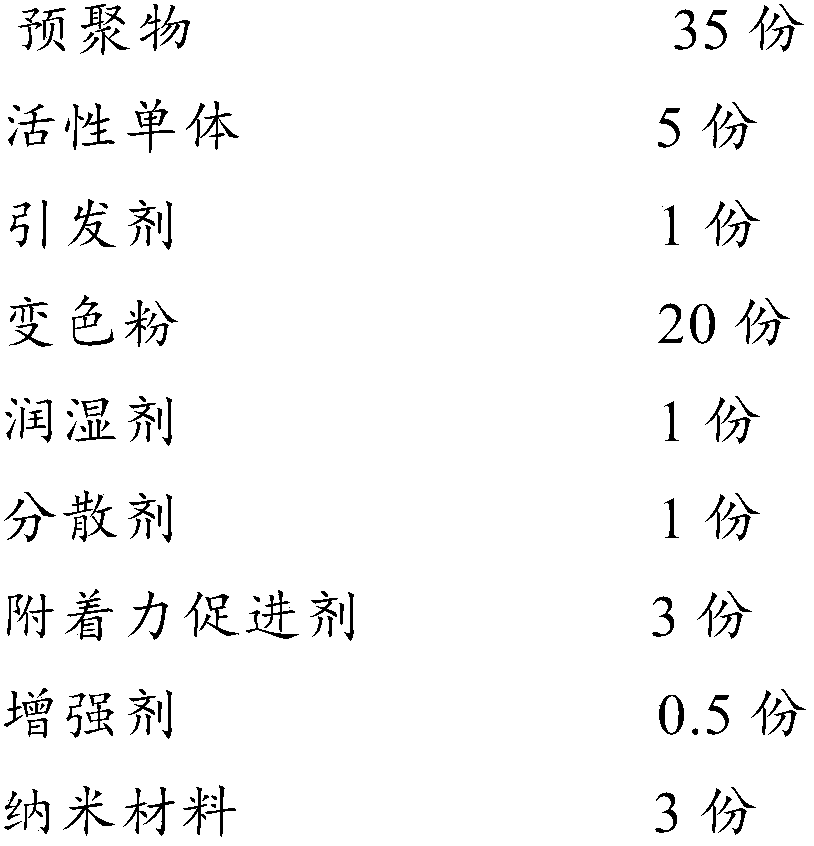

[0041] Prepare the photochromic glass coating with the raw materials in the following weight ratio.

[0042]

[0043] Among them, the prepolymer is epoxy acrylate; the active monomer is isobornyl acrylate, diethylene glycol diacrylate, and pentaerythritol tripropylene triester, and the weight ratio of the three is 1:2:0.5; the initiator is 1-hydroxy Cyclohexyl phenyl ketone, 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone, the weight ratio of the two is 1:0.5; discoloration Powder is M O o 3 , the average particle size is 1 micron; the wetting agent is TEGO-270; the dispersant is DISPERBYK-116; the adhesion promoter is aminopropylmethyldimethoxysilane; the reinforcing agent is KH550; the nanomaterial is zirconium dioxide, The average particle size is 50nm.

[0044] The specific preparation process method is the same as in Example 1.

[0045] After the prepared photochromi...

Embodiment 3

[0046] Embodiment 3: Preparation and detection of photochromic glass coating (three)

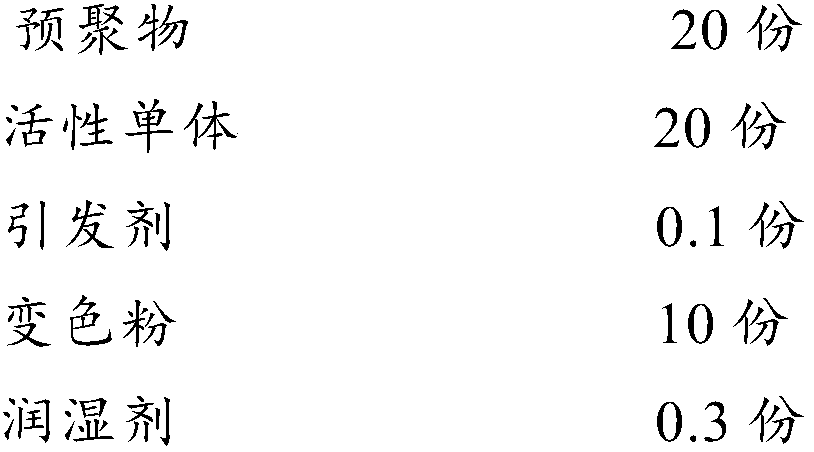

[0047] Prepare the photochromic glass coating with the raw materials in the following weight ratio.

[0048]

[0049]

[0050] The prepolymer is epoxy acrylate; the active monomer is hexanediol diacrylate and trimethylolpropane triacrylate, and the weight ratio of the two is 1:1; the initiator is 2-hydroxyl-2-methyl -1-phenylacetone, 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester, 2-dimethylamino-2-benzyl-1-[4-(4-morpholinyl)benzene Base] -1-butanone, the weight ratio of the three is 1:2:0.5; the color changing powder is benzopyran, the average particle size is 10 microns; the wetting agent is TEGO-280; the dispersant is DISPERBYK-112; The focus accelerator is aminopropyltriethoxysilane; the enhancer is DL602; the nanomaterials are aluminum oxide (average particle size 20nm) and silicon dioxide (average particle size 30nm), and the weight ratio of the two is 1:1 .

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com