Preparation method of composite nanostructure double-effect sulfur fixation type lithium-sulfur battery anode material

A composite nanostructure and cathode material technology, which is applied in the field of preparation of new energy materials, can solve problems such as side reactions and affecting the cycle stability of lithium-sulfur batteries, and achieve the effects of improving cycle life, improving electrochemical performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Put thioacetamide and stannous chloride with a molar ratio of 5:1 in a certain volume of isopropanol, stir magnetically for 90 minutes to form a clear solution, then add titanium dioxide nanotubes, and react at 170°C for 24 hours Obtained nanotube A modified by tin disulfide nanosheets 1 .

[0020] (2) Add a certain concentration of cysteine ligand to the nanotubes obtained in step (1), after vacuuming for 10 minutes, transfer the nanotubes to a blast drying oven, and dry at 60°C for 3 hours to obtain the ligand Further Modified Nanotube A 2 .

[0021] (3) Dissolve elemental sulfur in carbon disulfide, ultrasonically disperse to form a suspension, and pump the suspension to nanotube A by vacuuming 2 In the process, after evaporating the solvent, put it in a muffle furnace for 24 hours of low-temperature heat treatment at 155 ° C, and then naturally cool to room temperature to obtain the composite material.

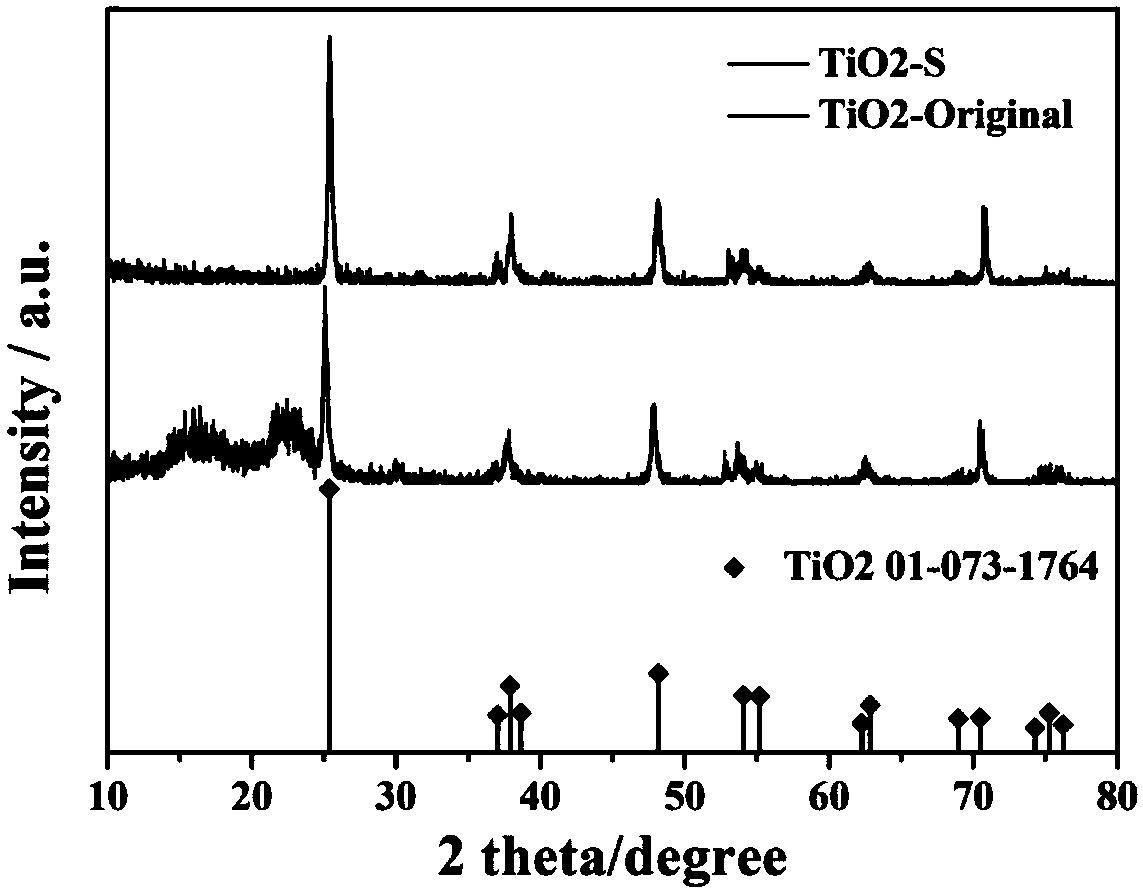

[0022] figure 1 The X-ray diffraction pattern of th...

Embodiment 2

[0024] (1) Put thioacetamide and cobalt acetate at a molar ratio of 6:1 in a certain volume of n-propanol, stir magnetically for 70 minutes to form a clear solution, then add titanium dioxide nanotubes, react at 190°C for 18 hours to obtain vulcanization Cobalt nanosheet-modified nanotube A 1 .

[0025] (2) Add a certain concentration of glycine ligand to the nanotubes obtained in step (1), and after evacuating for 20 minutes, transfer the nanotubes to a blast drying oven, and dry them at 80°C for 2 hours to obtain further modified ligands. Nanotube A 2 .

[0026] (3) Dissolve elemental sulfur in carbon disulfide, ultrasonically disperse to form a suspension, and pump the suspension to nanotube A by vacuuming 2 The composite material was obtained after evaporating the solvent to dryness and putting it into a muffle furnace for 14 hours of low-temperature heat treatment at 165°C, and then cooling it naturally to room temperature.

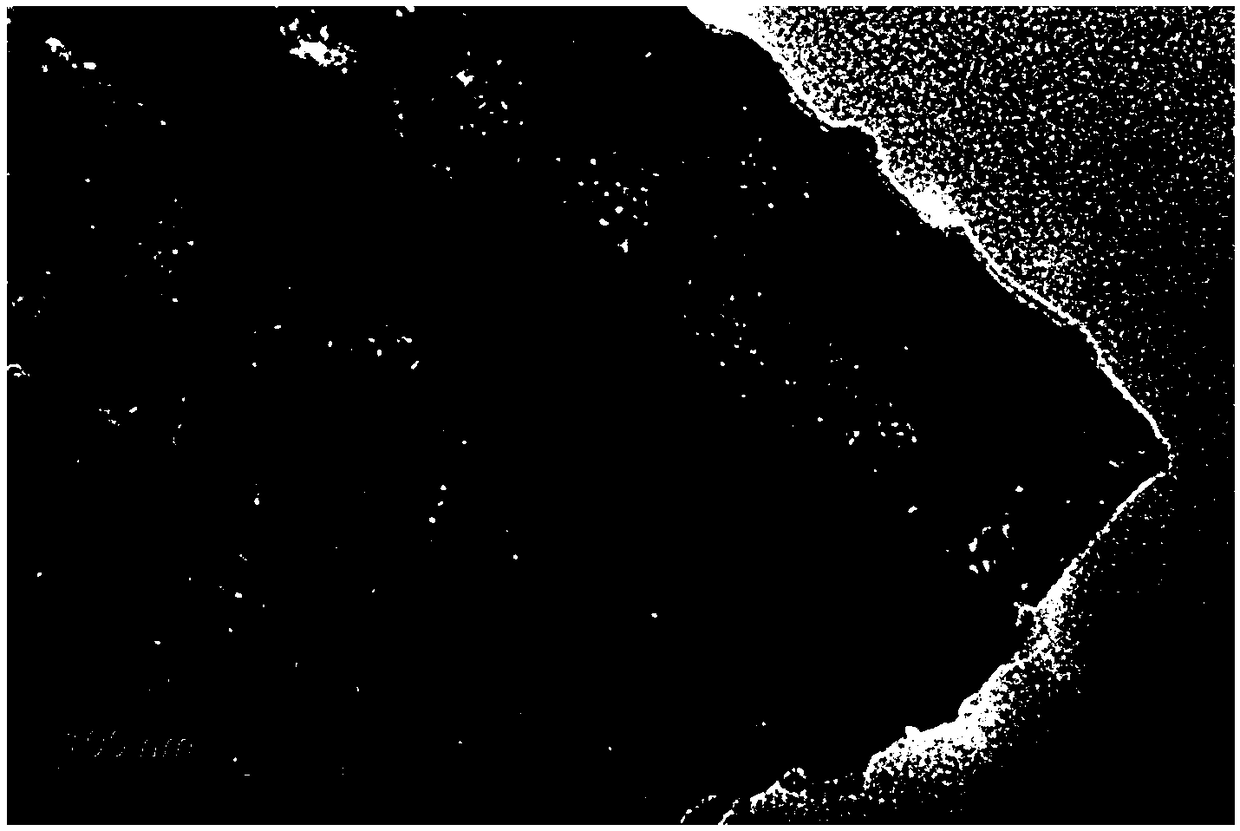

[0027] figure 2 It is a scanning electro...

Embodiment 3

[0029] (1) Put thiourea and tin tetrachloride at a molar ratio of 6:1 in a certain volume of n-butanol, stir magnetically for 30 minutes to form a clear solution, then add vanadium oxide nanotubes, and react at 190°C for 12 hours to obtain Nanotubes A decorated with vanadium sulfide nanosheets 1 .

[0030] (2) Add a certain concentration of thioglycolic acid ligand to the nanotubes obtained in step (1), and after vacuuming for 30 minutes, transfer the nanotubes to a blast drying oven, and dry them at 90°C for 2 hours to obtain the ligands Further Modified Nanotube A 2 .

[0031] (3) Dissolve elemental sulfur in carbon disulfide, ultrasonically disperse to form a suspension, and pump the suspension to nanotube A by vacuuming 2 In the process, after evaporating the solvent, put it into a muffle furnace for 185°C low-temperature heat treatment for 12 hours, and then naturally cool to room temperature to obtain the composite material.

[0032] image 3 It is a transmission el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com